Signal processing method of gas ultrasonic flowmeter based on echo rising segment peak fitting and echo energy point positioning

A technology of echo signal and signal processing, which is applied in the direction of measuring flow/mass flow, measuring device, liquid/fluid solid measurement, etc., and can solve problems such as difficult to determine the arrival time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

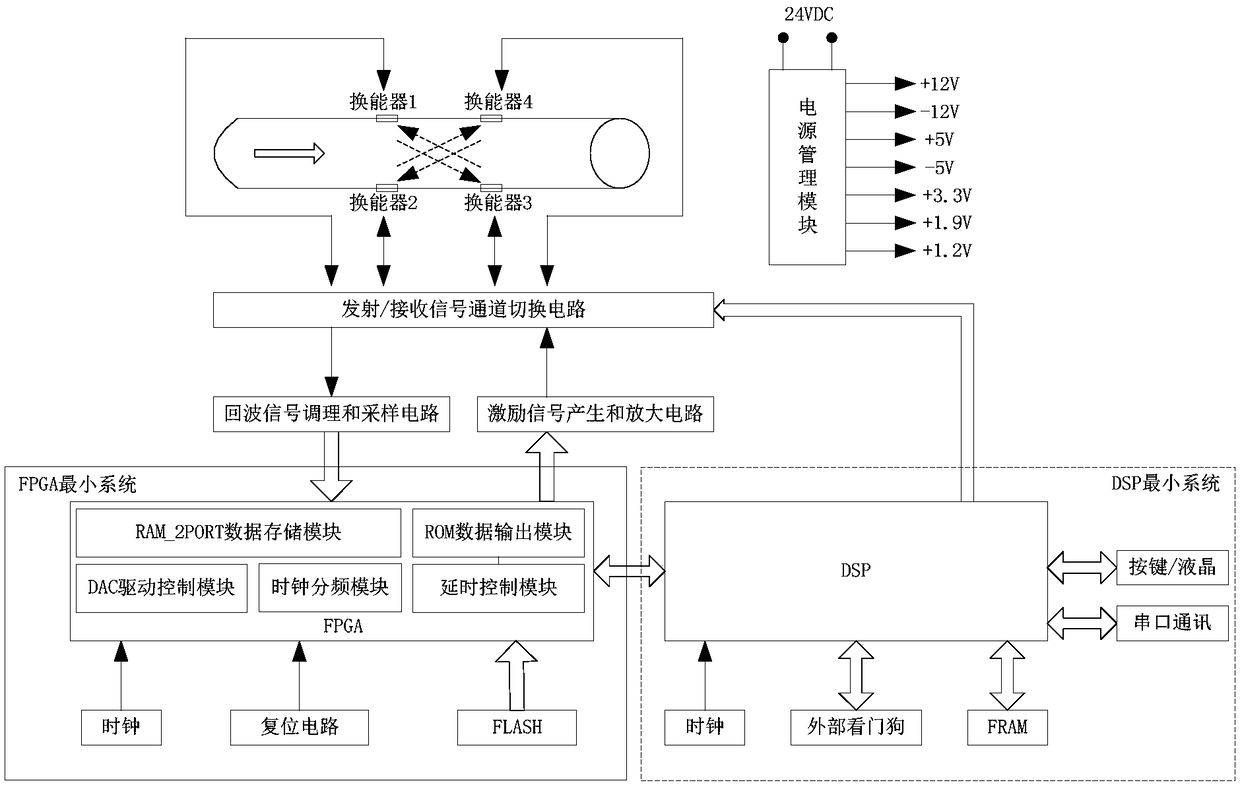

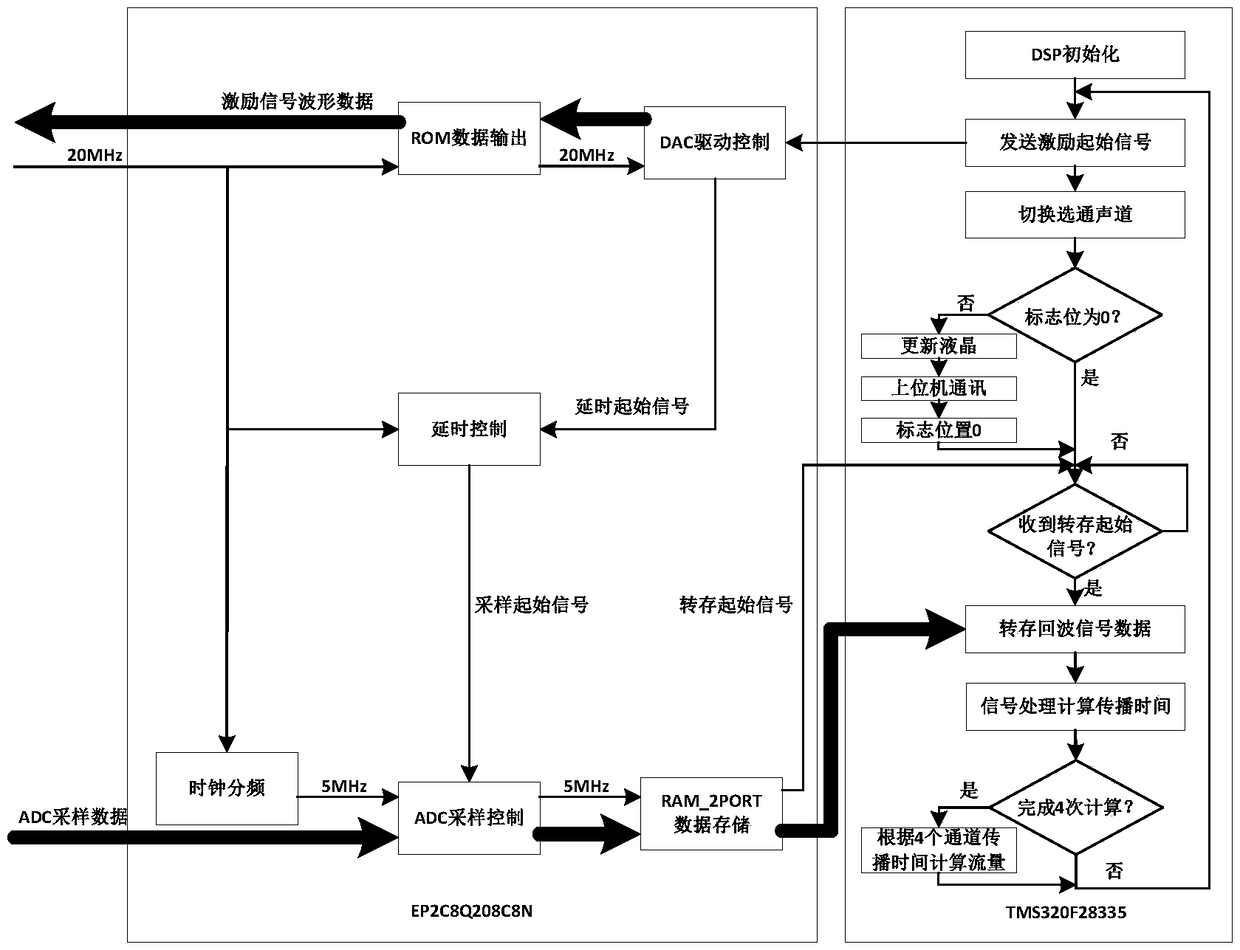

[0035] See figure 1 The hardware system of the present invention is composed of a transducer unit, a transmission / reception signal channel switching circuit, an excitation signal generation and amplification circuit, an echo signal conditioning and sampling circuit, a DSP minimum system, an FPGA minimum system and a power management module.

[0036] The transducer unit is composed of four transducers, which are respectively fixedly installed on the pipeline for conveying gas flow; the four transducers are transducer 1, transducer 2, transducer 3, and transducer. 4. Set up as a direct-fired two-channel structure; each transducer is used as both a transmitting transducer and a receiving transducer.

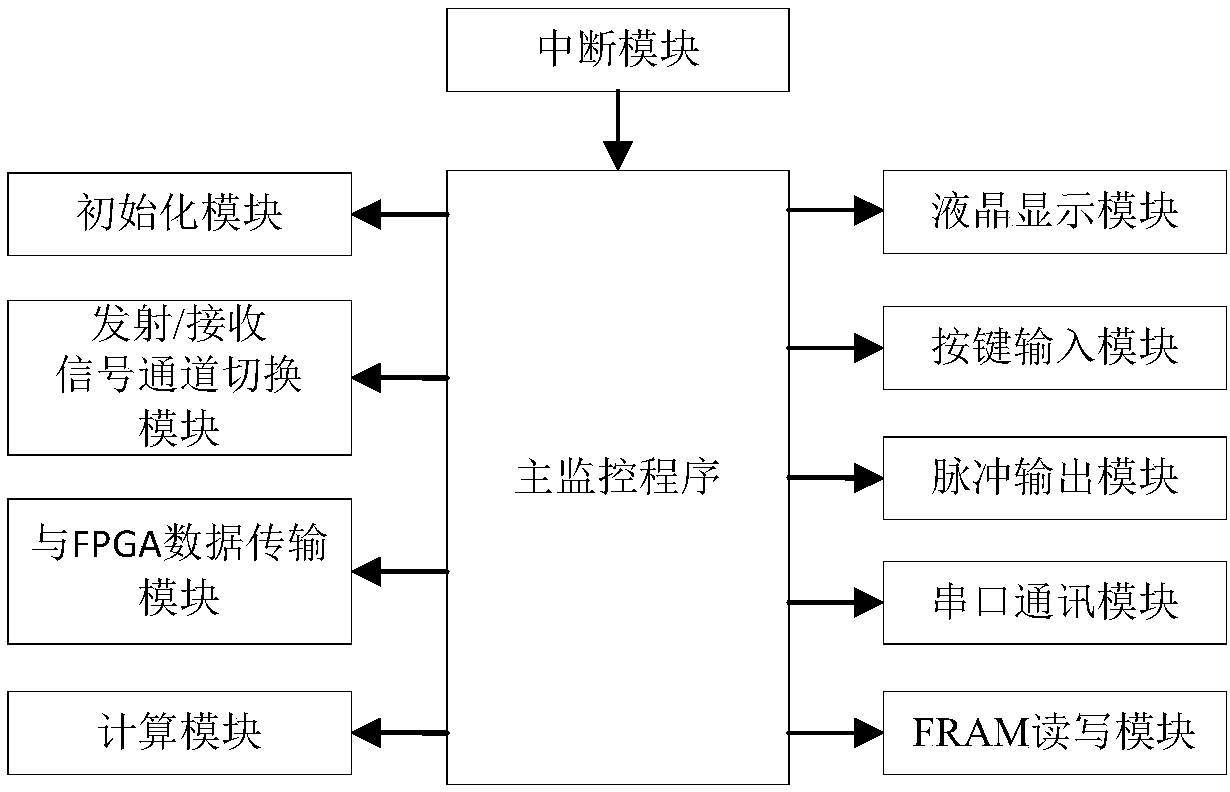

[0037] The DSP minimum system consists of a DSP chip, a clock module, an external watchdog module, a FRAM (ferroelectric memory) module, a serial communication module, and a button / liquid crystal module. The model of the DSP chip is TMS320F28335.

[0038] The FPGA minimum system consists ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com