A long time high temperature wind tunnel test chamber

A wind tunnel test, long-term technology, applied in aerodynamic test, machine/structural component test, instrument and other directions, can solve problems such as small heat flow, achieve the effect of simple structure and meet thermal protection technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

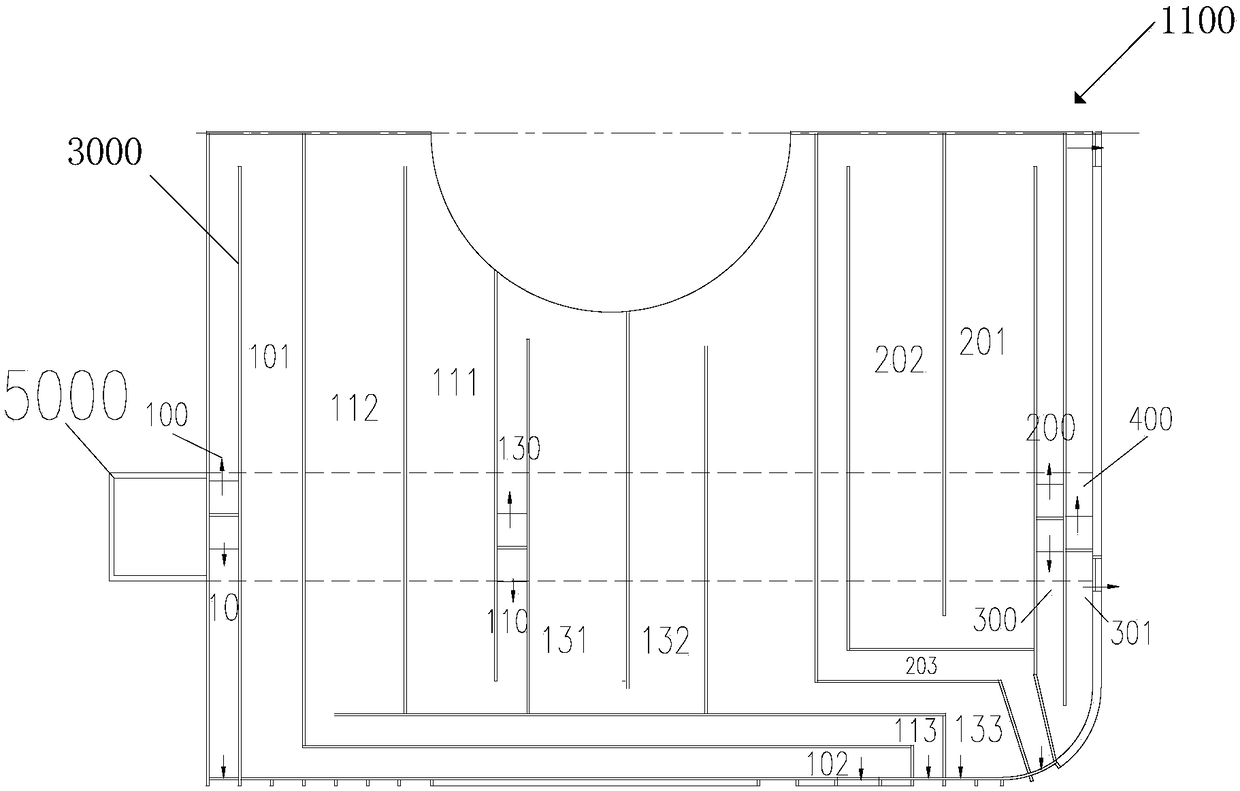

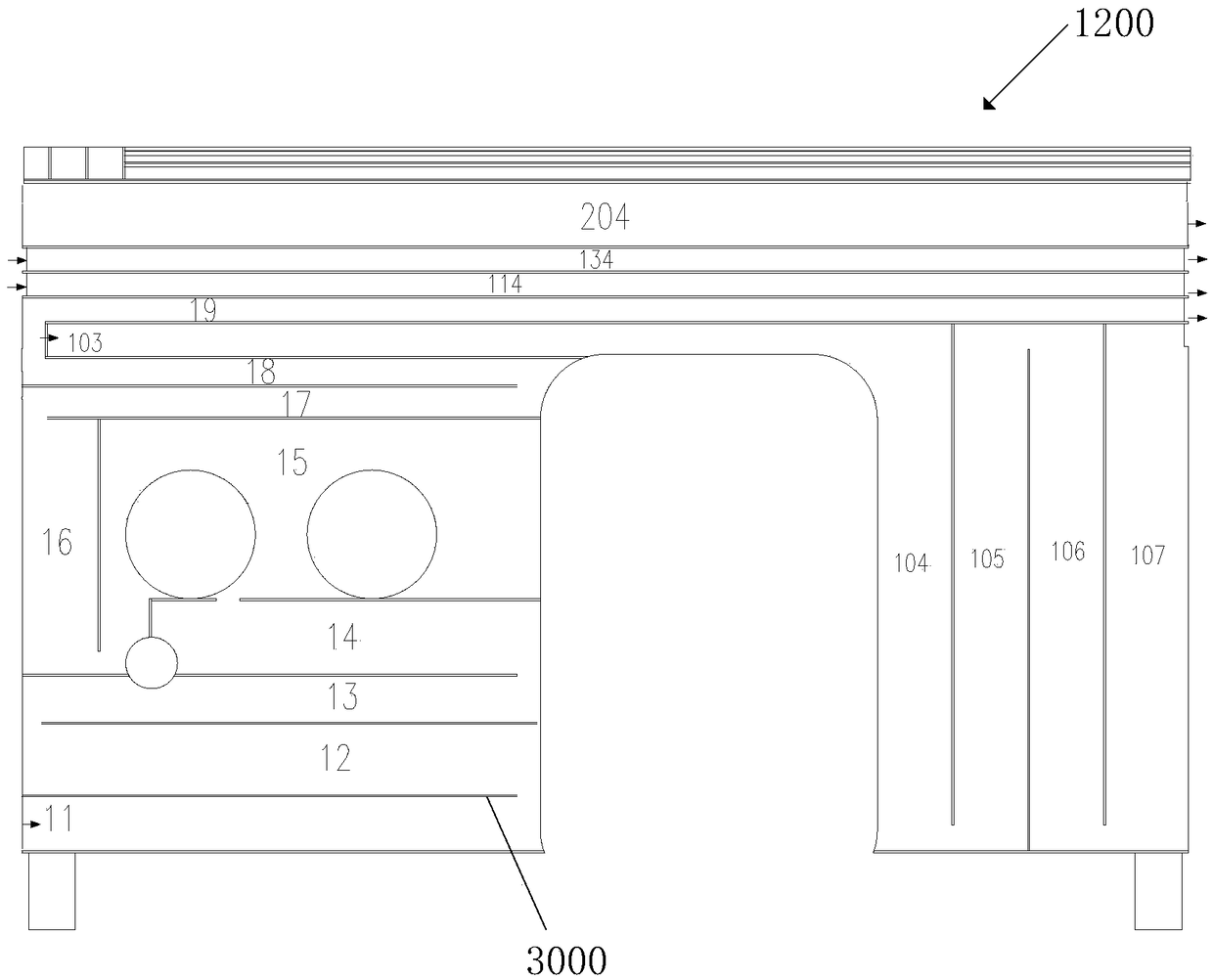

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

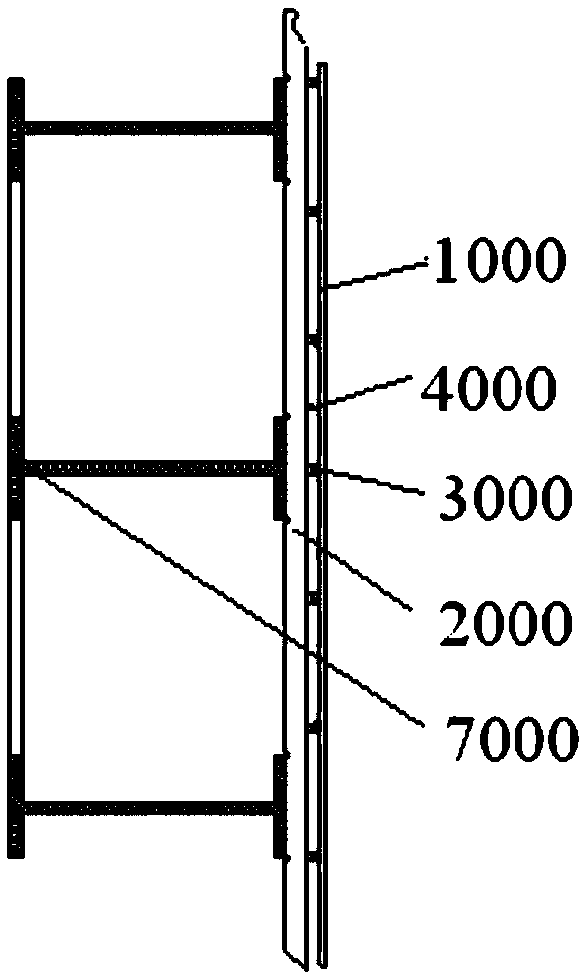

[0033] figure 1It is a structural schematic diagram of the bulkhead of the long-time high-temperature wind tunnel test chamber of the present invention. Such as figure 1 As shown, the long-term high-temperature wind tunnel test cabin includes a bulkhead, and the bulkhead includes an inner wall 1000 and an outer wall 2000; wherein, the inner wall 1000 and the outer wall 2000 are connected by a partition 3000 to form a water cooling channel 4000, and cooling water is introduced into the water cooling channel 4000 .

[0034] In this embodiment, a water-cooling channel is provided between the inner wall and the outer wall of the bulkhead, so that the water-cooling channel of the entire bulkhead is filled with cooling water, and the heat of the wall surface is taken away by means of forced convection heat exchange between the cooling water and the wall surface, ensuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com