Easy-to-sew multilayer composite woven body and application thereof

A multi-layer composite and braided technology, which is applied in the direction of multi-strand fabrics, textiles, fabrics, etc., can solve the problems of braid damage, braids are difficult to achieve rapid high strength, etc., to prevent separation, increase seamability, and scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

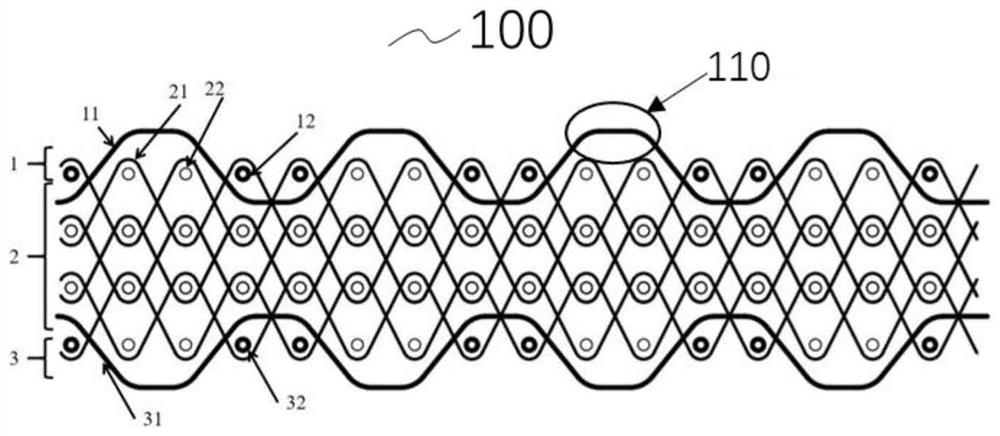

[0054] An easily sutured high-temperature-resistant heat-insulating braided body, comprising: upper-layer stitching warp yarns 11 and upper-layer stitching weft yarns 12 interlaced in sequence from top to bottom; high-temperature-resistant interlaced warp yarns 21 and high-temperature-resistant weft yarns 22; lower-layer stitching warp yarns 31 and lower layer stitching yarns Weft 32.

[0055] Wherein, the upper stitched warp yarns 11 and the upper stitched weft yarns 12 are interwoven to form the upper stitched layer 1 , the high temperature resistant interlaced warp yarns 21 and the high temperature resistant weft yarns 22 are interwoven to form the middle layer functional layer 2 , and the lower stitched warp yarns 31 and the lower layer stitched weft yarns 32 are interwoven to form the lower stitched layer 3 . The middle functional layer 2 is a middle heat insulating layer, which is used to prepare a heat insulating and protective braid.

[0056] In the upper stitched lay...

Embodiment 2

[0061] The difference between Example 2 and Example 1 is:

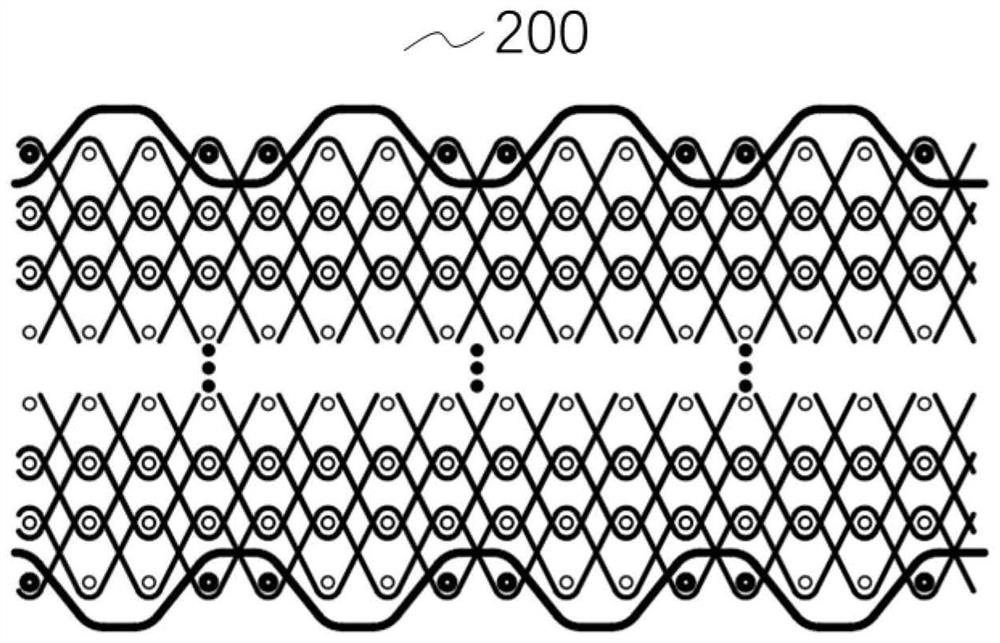

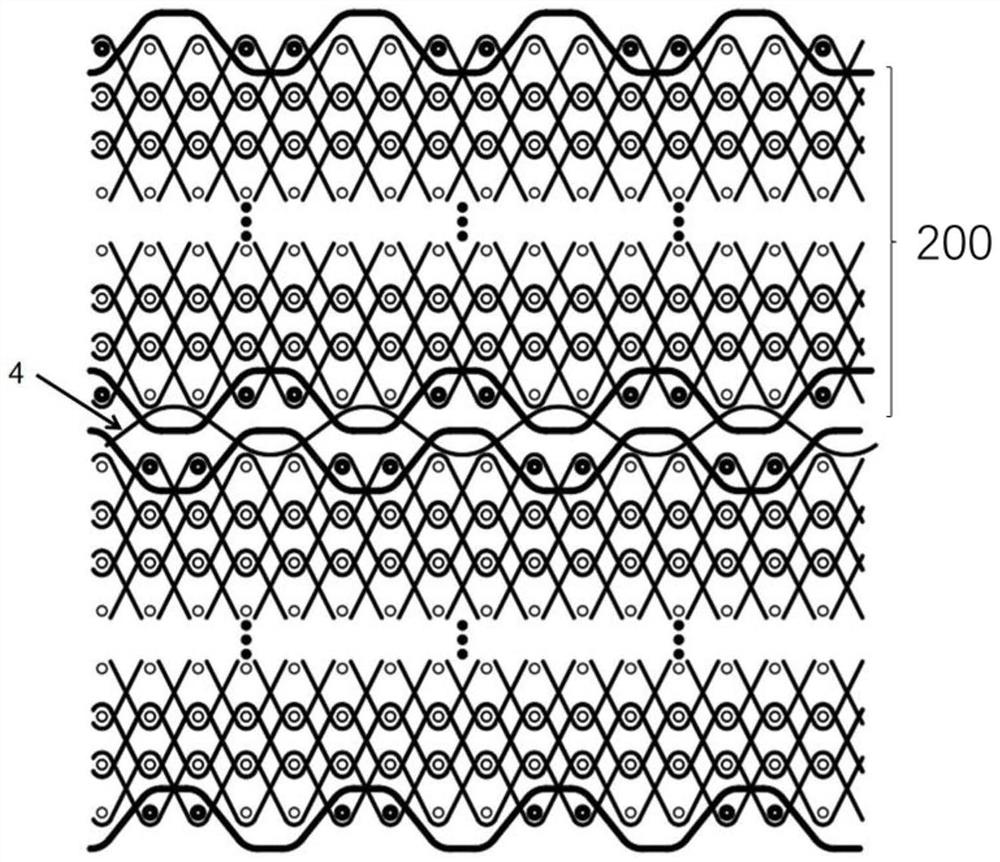

[0062] There are 2-10 layers of high temperature resistant weft yarns 22 (such as figure 2 shown);

[0063] The surface warp density of the upper seam layer 1 and the lower seam layer 3 is 6 pieces / cm, the surface weft density is 4 pieces / cm, the surface warp density of the middle functional layer 2 is 6 pieces / cm, and the surface weft density is 4 pieces / cm. . The upper stitched warp yarn 11, the upper stitched weft yarn 12, the high-temperature-resistant interlocking warp yarn 21, the high-temperature resistant weft yarn 22, the lower-layer stitched warp yarn 31, the lower-layer stitched weft yarn 32 and the high-strength stitching thread 4 are all made of glass fiber, and the high-temperature resistant interlocking warp yarn 21 and the high-temperature resistant weft yarn 22 The fineness of the upper stitching warp yarn 11, the upper stitching weft yarn 12, the lower stitching warp yarn 31, the lower stitching w...

Embodiment 3

[0066] Example 3 is basically the same as Example 2, except that:

[0067] The upper stitched warp yarns 11, the upper stitched weft yarns 12, the high-temperature-resistant interlaced warp yarns 21, the high-temperature resistant weft yarns 22, the lower-layer stitched warp yarns 31, the lower-layer stitched weft yarns 32 and the high-strength sutures 4 are all made of quartz fibers. The fineness of the high temperature resistant interlaced warp yarn 21 and the high temperature resistant weft yarn 22 is 390tex, and the fineness of the upper stitched warp 11, the upper stitched weft 12, the lower stitched warp 31, the lower stitched weft 32, and the high-strength suture 4 is 780tex.

[0068] The thermal insulation fabric of this embodiment is suitable for use in an environment of 800°C to 1000°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com