Spatial resolution test board and spatial resolution test method for electroluminescent defect detector

A spatial resolution and luminescence technology, which is applied in optical instrument testing, machine/structural component testing, optical performance testing, etc., can solve problems such as inapplicable electroluminescent defect detectors, and achieve easy results and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

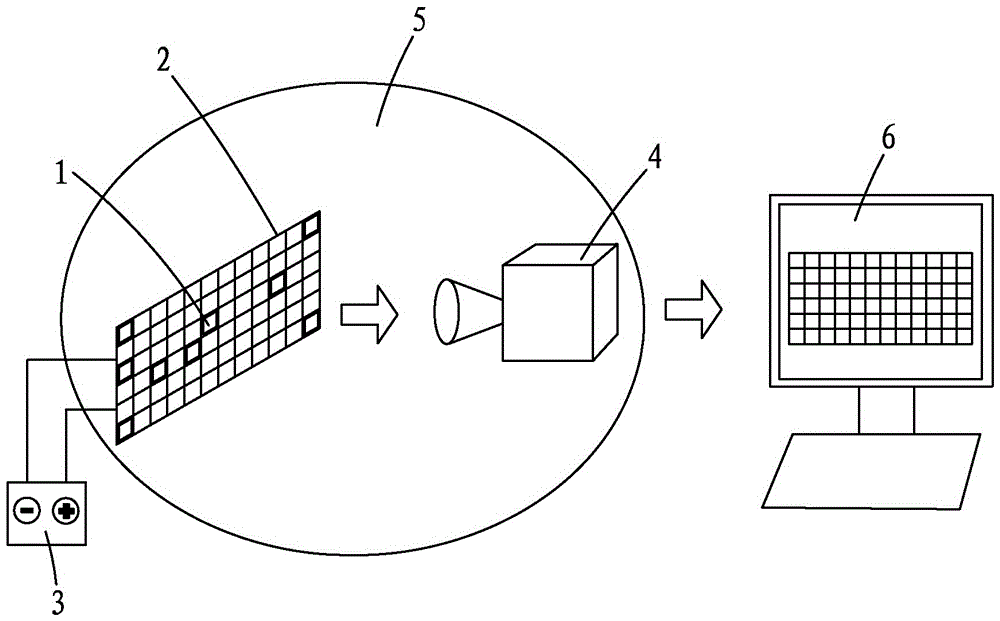

Embodiment 1

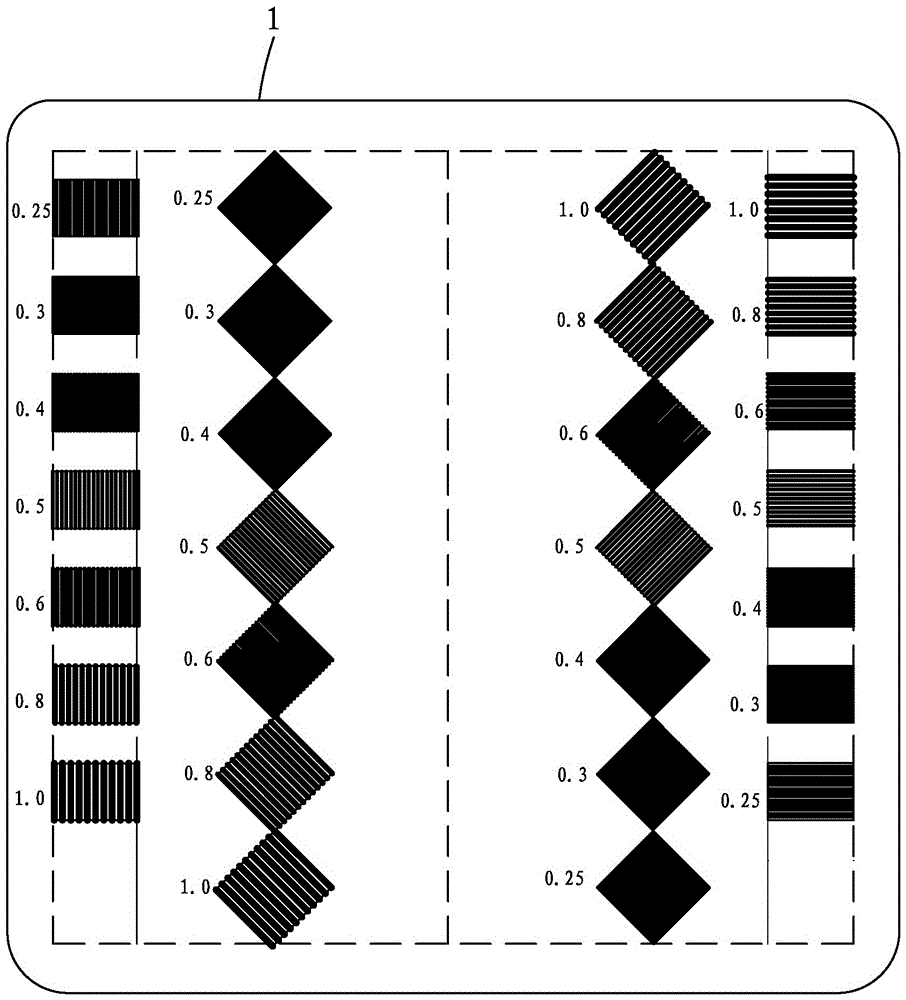

[0039] Such as figure 1As shown, four detection block groups are distributed on the spatial resolution test board 1, and each of the detection block groups includes a plurality of detection squares with different stripe line widths, and each of the detection squares is composed of a plurality of identical lines. Wide black and white spaced line pair stripes, the direction of the line pair stripes in different detection block groups is different, the direction of the line pair stripes in the same detection block group is the same, and the directions of the line pair stripes in the detection block group are horizontal direction, Vertical direction, left oblique direction of 45° and right oblique direction of 45°; the width of a single stripe in the line pair stripes ranges from 0.25mm to 1.0mm, and the plurality of detected squares in each detection block group The line width of the stripes between the detection squares is arranged gradually; the spatial resolution test board 1 ...

Embodiment 2

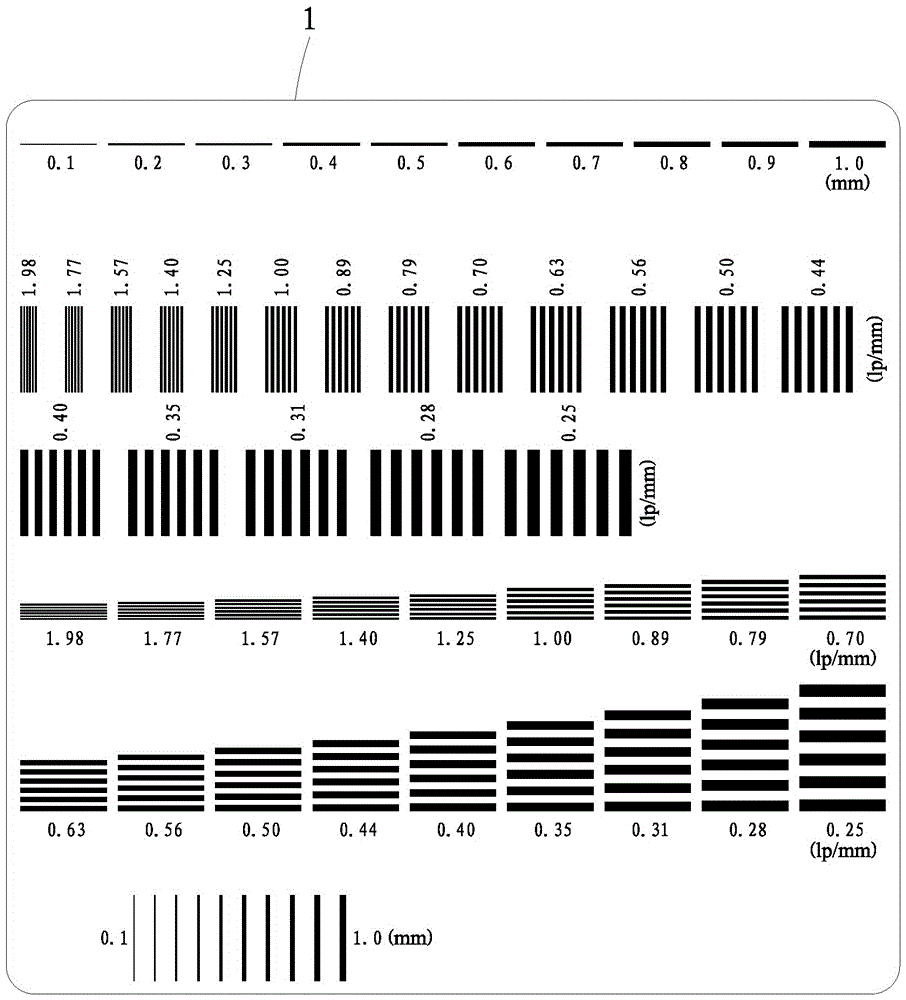

[0041] Such as figure 2 As shown, two detection square groups are distributed on the said spatial resolution test board 1, each said detection square group comprises a plurality of detection squares with different stripe line widths, and each said detection square consists of a plurality of identical lines Wide black and white spaced line pair stripes, the direction of the line pair stripes in different detection block groups is different, the direction of the line pair stripes in the same detection block group is the same, and the directions of the line pair stripes in the detection block group are horizontal direction and horizontal direction respectively. Vertical direction: the width of a single stripe in the line pair stripes ranges from 0.1mm to 2.0mm, and the width of a single stripe in a plurality of detection squares in each detection square group is in a proportional sequence or an equal difference Regular distribution of sequences; the spatial resolution test board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com