Heat dissipation device and combined heat dissipation device

A technology of heat dissipation device and drive structure, which is used in instruments, electrical digital data processing, digital data processing parts, etc. The fan is not easy to customize and other problems, to achieve the effect of simple structure, long service life, simple disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

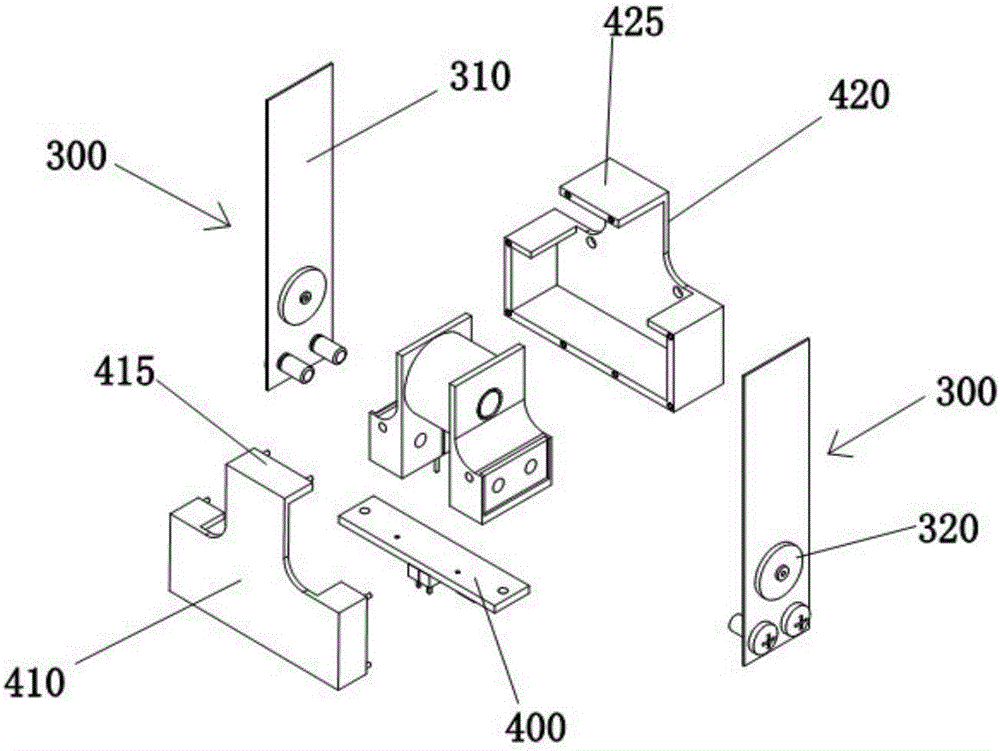

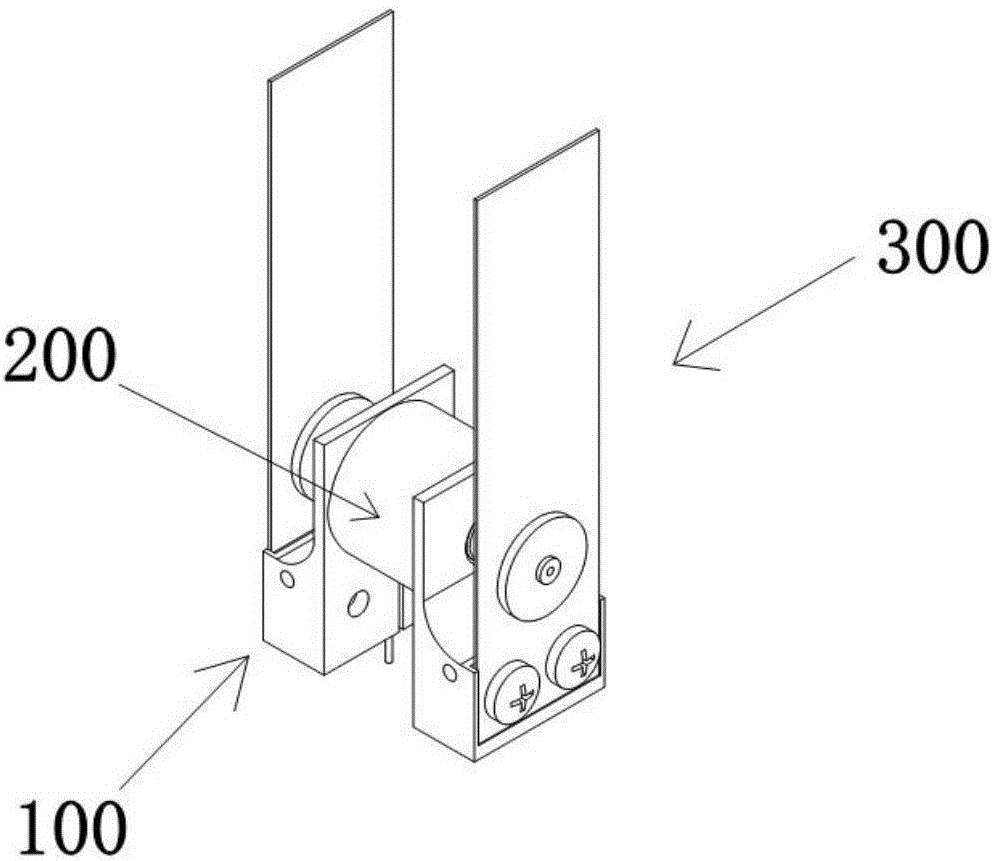

[0031] Such as Figure 1 to Figure 5 As shown, the heat dissipation device provided by the present invention includes a base 100, a driving structure 200 capable of generating a periodic magnetic field, and at least one swinging structure 300. The driving structure 200 is installed on the base 100 for adjusting the swinging frequency of the swinging structure 300. The frequency adjustment module 400 is electrically connected to the drive structure 200, the frequency adjustment module 400 is connected to an external power supply, the fixed end of the swing structure 300 is installed on the base 100, and the swing structure 300 is opposite to the magnetic pole of the drive structure 200, and the free end of the swing structure 300 is driven Under the action of the structure 200, it swings back and forth.

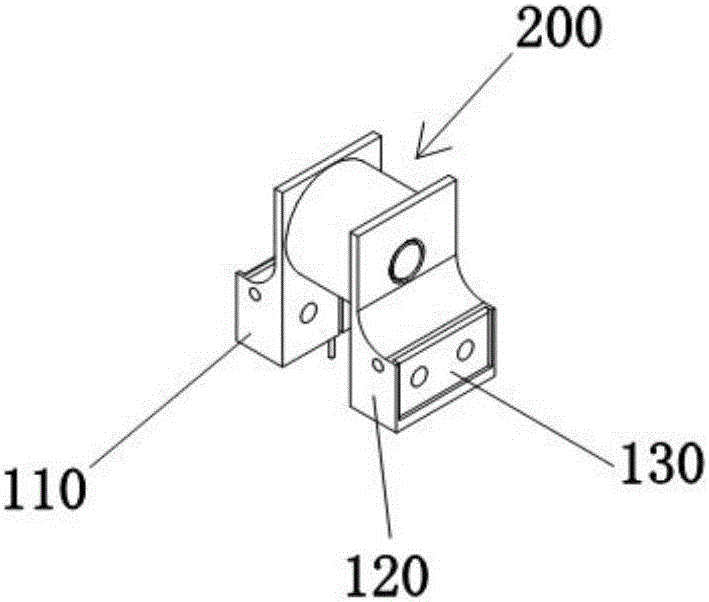

[0032] As a possible implementation manner, the base 100 includes a first base 110 and a second base 120 , and the first base 110 and the second base 120 are both provided wit...

Embodiment 2

[0041] On the basis of Embodiment 1, the present invention also provides a combined heat dissipation device, which also includes a housing, wherein there are multiple bases 100, driving structures 200 and swing structures 300, and a plurality of In the cavity containing the driving structure 200 and the base 100, a plurality of driving structures 200 and the base 100 are sequentially installed in the inner cavity, the iron cores 210 of the multiple driving structures 200 are coaxial, and the magnetic pole directions of adjacent driving structures 200 are opposite , a plurality of drive structures 200 are electrically connected to the frequency adjustment module 400, fixed ends of a plurality of swing structures 300 are sequentially installed between adjacent drive structures 200, and free ends of the swing structures 300 are driven by the drive structure 200 to swing back and forth.

[0042] The present invention adopts the above technical scheme, and the technical effect achie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com