Power transmission lead wire temperature detection method, maximum current carrying capacity detection method and system thereof

A technology of power transmission wire and detection method, applied in the field of power transmission and distribution, can solve problems such as inaccurate test results, and achieve the effects of improving transmission capacity, improving stability, and saving investment in monitoring equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation of the method and system for forecasting industry power demand of the present invention will be described in detail below in conjunction with the accompanying drawings.

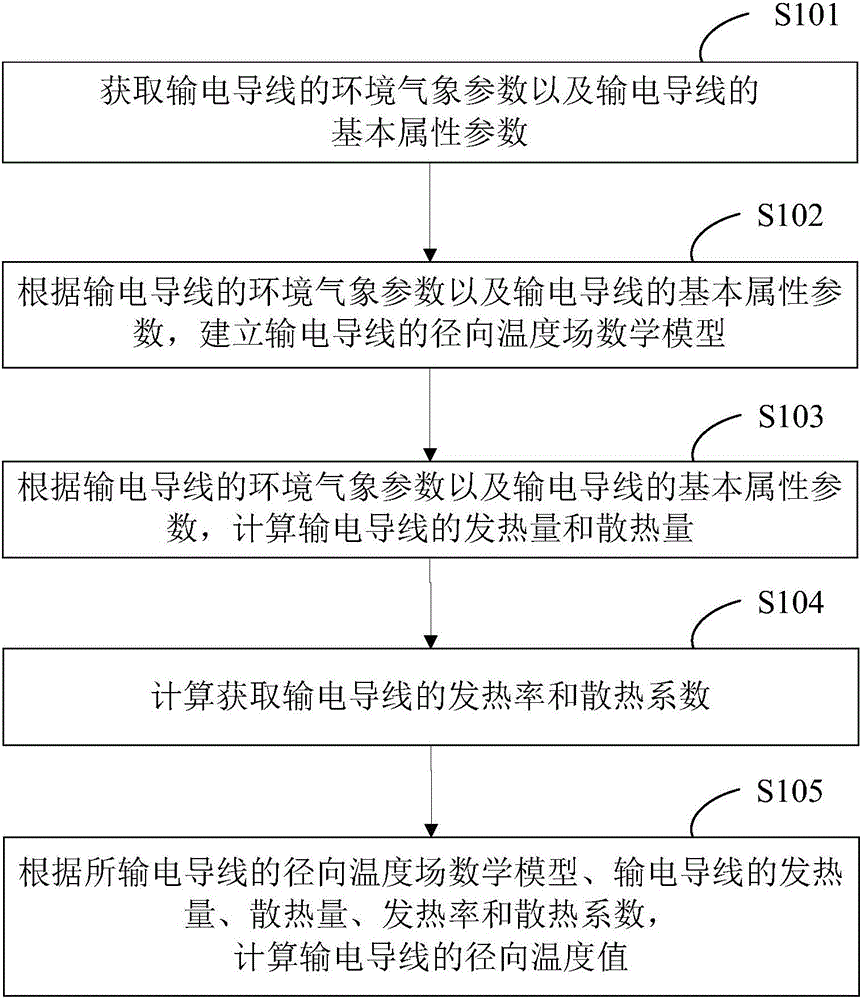

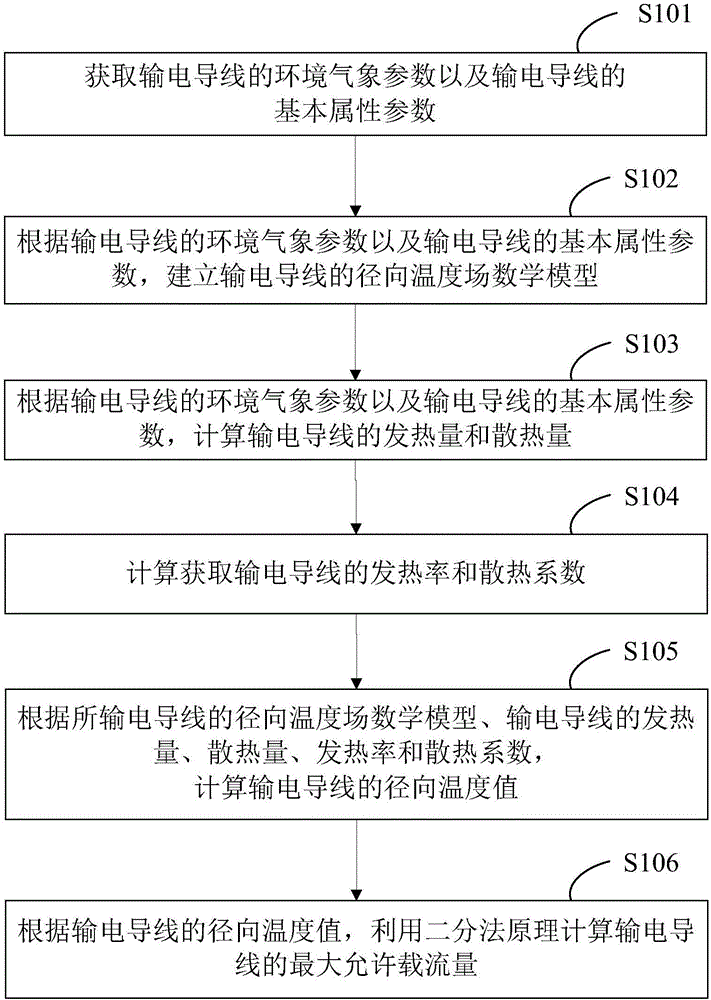

[0046] reference figure 1 , figure 1 Shown is a flowchart of a method for detecting the temperature of a power transmission wire in an embodiment.

[0047] The method for detecting the temperature of a transmission wire is characterized in that it comprises the following steps:

[0048] S101: Obtain environmental meteorological parameters of the transmission wire and basic attribute parameters of the transmission wire;

[0049] S102: Establish a mathematical model of the radial temperature field of the transmission conductor according to the environmental meteorological parameters of the transmission conductor and the basic attribute parameters of the transmission conductor;

[0050] S103: Calculate the heat generation and heat dissipation of the power transmission wire according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com