A Crack Prediction Method for Aeroengine Blades

A technology for aero-engine and blade cracks, which is applied in the field of aero-engines, can solve the problems of high test cost, inability to describe, and difficulty in considering real blade twist and variable cross-section characteristics, and achieve the effect of reducing test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

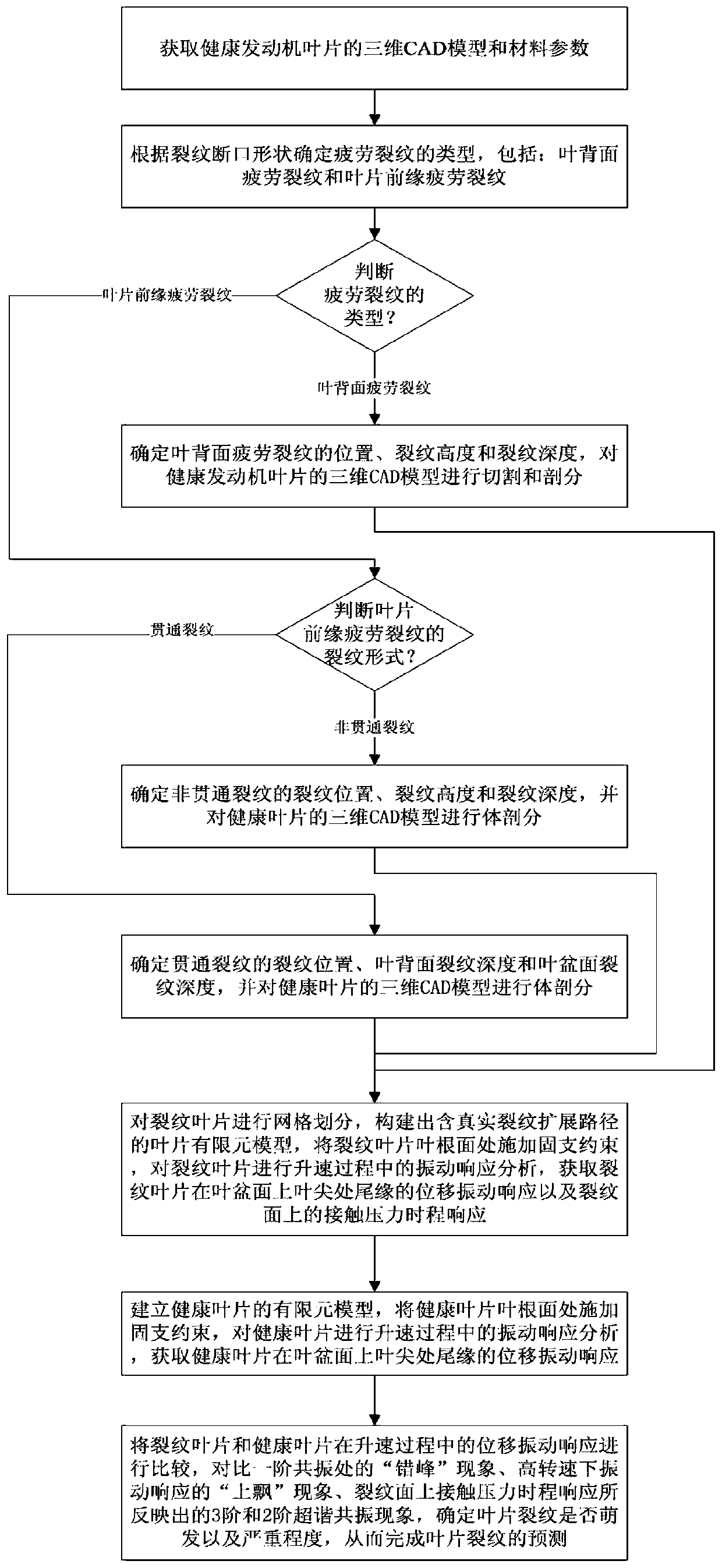

[0066] In the embodiment of the present invention, the aeroengine blade crack prediction method, such as figure 1 shown, including the following steps:

[0067] Step 1, obtain the 3D CAD model and material parameters of the healthy engine blade;

[0068] In the embodiment of the present invention, the three-dimensional CAD model of healthy blade is as figure 2 As shown, the blade material is selected as TA11 alloy, and the material performance data at room temperature are as shown in Table 1, including: modulus of elasticity, Poisson's ratio and material density; the present invention assumes that the blade is an isotropic linear elastic material;

[0069] Table 1 Material property data of TA11 at room temperature

[0070]

[0071] Step 2. Determine the type of fatigue cracks according to the shape of the crack fracture, including: fatigue crack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com