Passive Spent Fuel Cooling Storage Unit

A technology for storage devices and spent fuel, applied in cooling devices, reactor fuel elements, nuclear power generation, etc., can solve problems such as unsuitable for storage, and achieve the effects of simple structure, low operating cost, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Using the passive spent fuel cooling storage device of the present invention to store spent fuel discharged from a nuclear reactor, the steps are as follows:

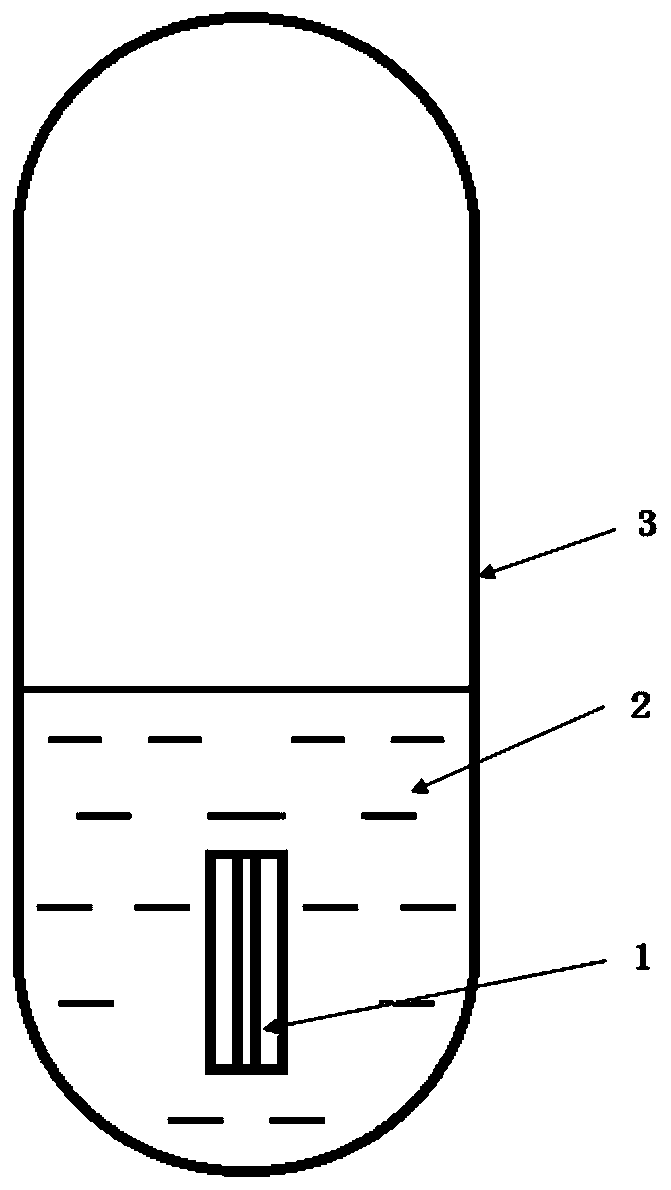

[0027] (1) Place the pressure-tight shell 3 that has been welded on the lower head in the hot chamber, and inject coolant 2 that accounts for about 20% of its volume into the pressure-tight shell 3;

[0028] (2) placing the spent fuel 1 to be stored on the spent fuel support in the coolant 2, and the coolant 2 is water;

[0029] (3) Weld the upper head of the pressure-tight shell 3, and store it after leak detection.

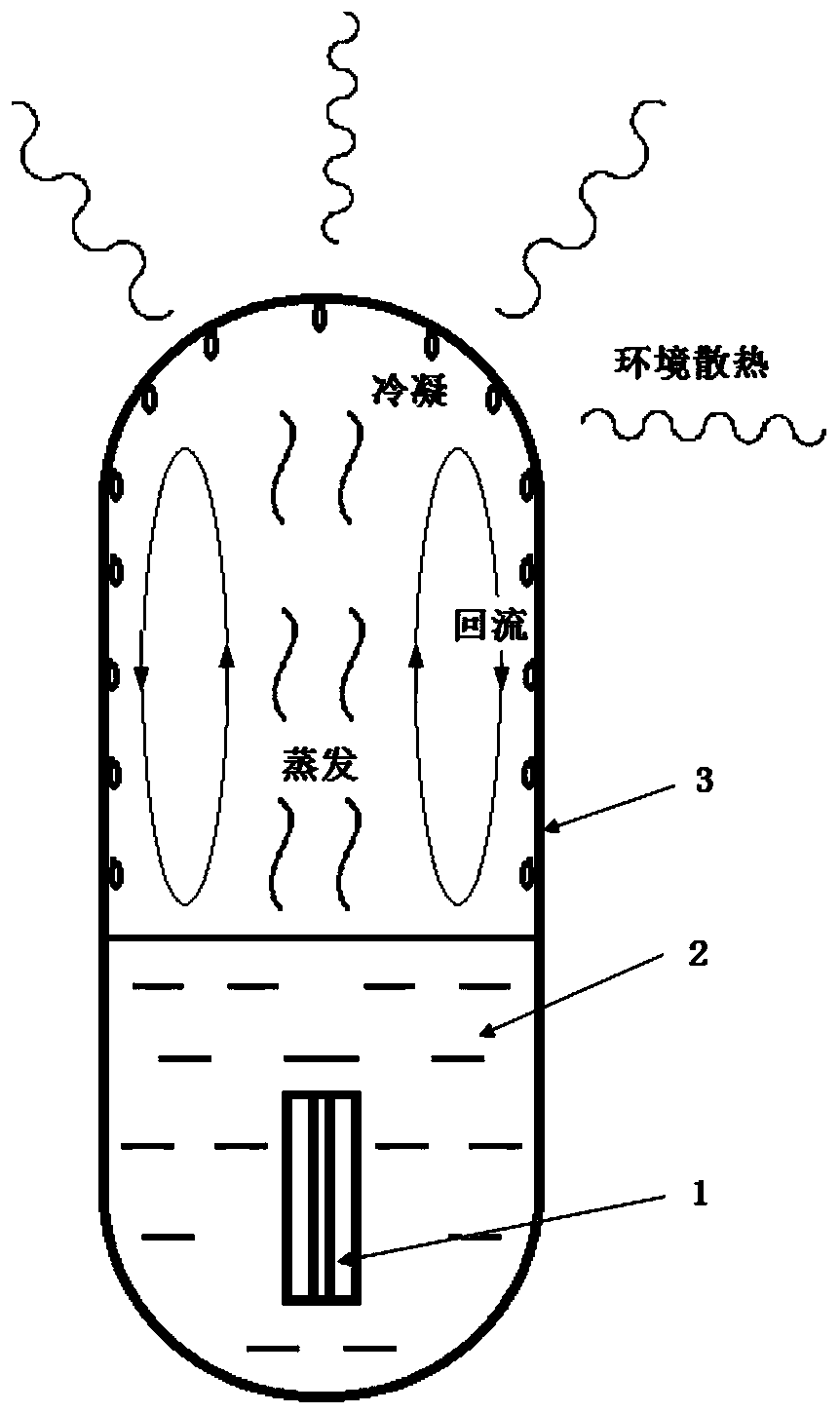

[0030] The temperature of the outer wall of the passive spent fuel cooling storage device stored in Example 1 was monitored, and the monitoring data showed that the temperature continued to rise within 3 days. After 3 days, the temperature of the outer wall of the pressure-sealed vessel no longer increased, indicating that the passive spent fuel cooling storage device reached the balance of heat g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com