Anti-water industrial plug with automatic lock

A plug and industrial technology, which is applied in the field of industrial plugs, can solve problems such as complex structure, low assembly efficiency, and high production cost, and achieve the effects of simple overall structure, increased safety, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

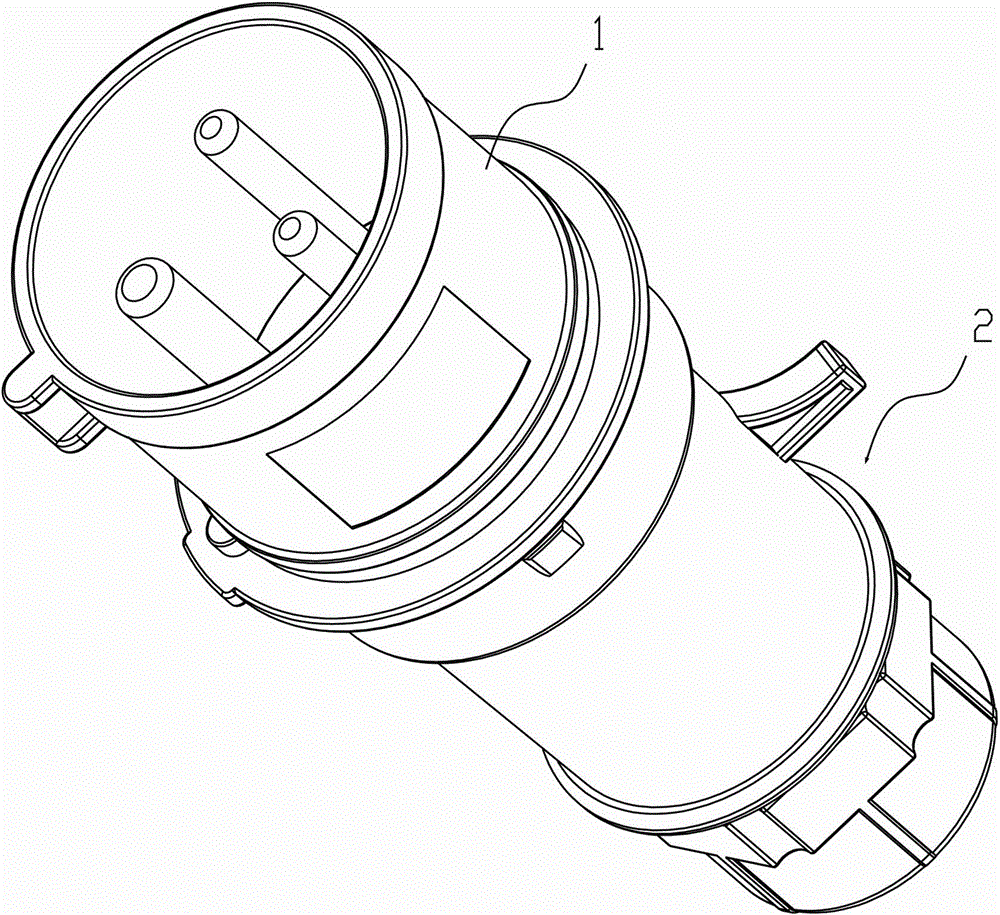

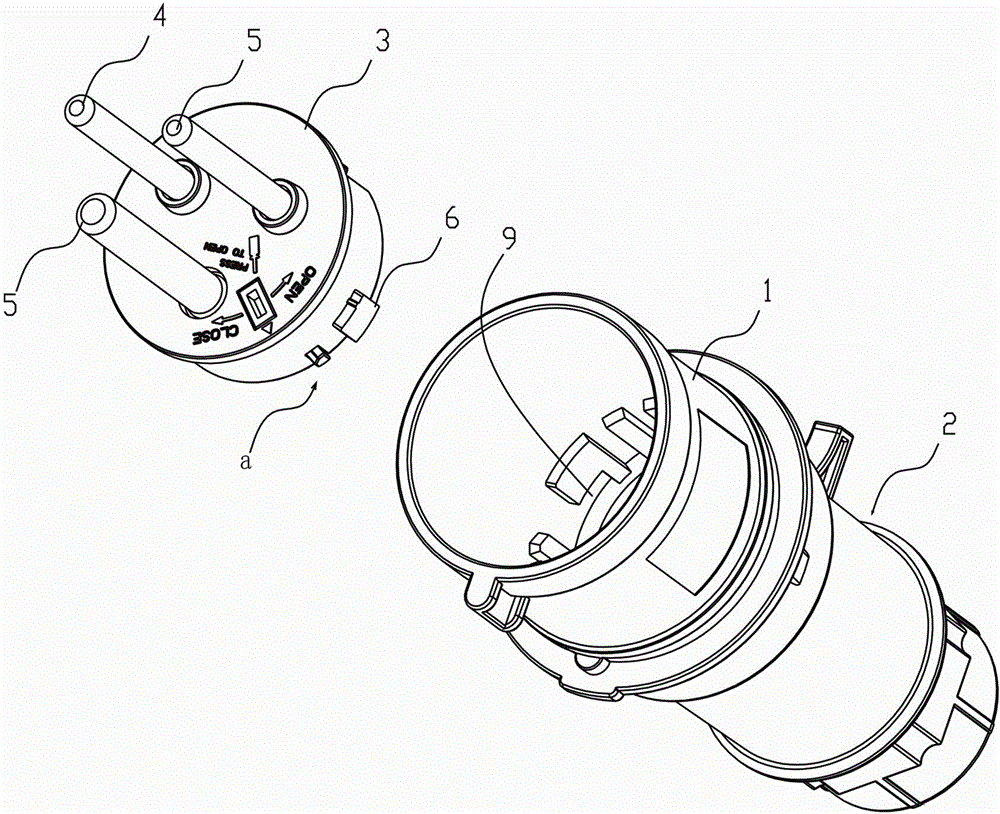

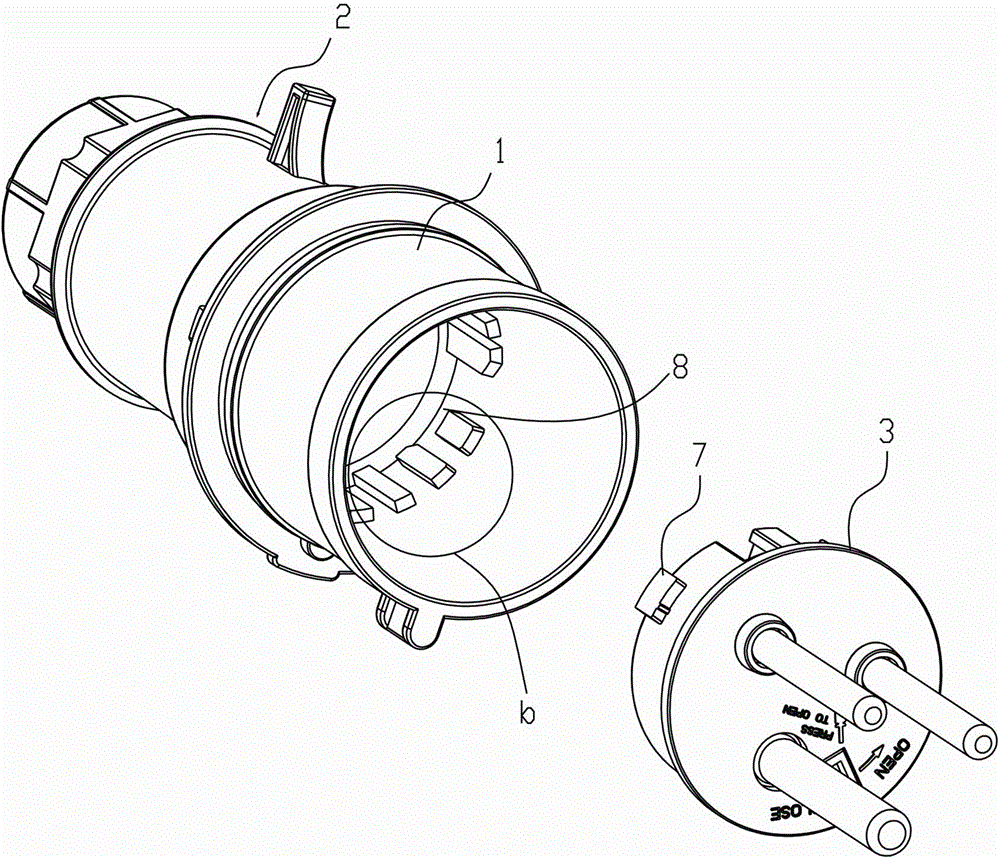

[0022] Such as Figure 1-7 As shown, a waterproof industrial plug with an automatic locking function of the present invention includes an integrally formed plug base 1, a plug sheath assembly 2, and the plug sheath assembly 2 includes a sheath body 201 and a bottom screw Fastener 202. The plug base 1 is fitted with a ferrule mounting seat 3, and the end face of the ferrule mounting seat 3 is inserted with a grounding ferrule assembly 4 and two live wire ferrule assemblies 5, and the bottom of the side of the ferrule mounting seat 3 There are symmetrical first locking protrusions 6 and second locking protrusions 7 , and an automatic locking component a is provided on the side of the ferrule mounting seat 3 corresponding to the first locking protrusions 6 .

[0023] The automatic locking assembly a includes a rotating block a1 installed in the groove 8 of the ferrule mounting seat 3 and a rotating shaft a2 extending from the lower end of the rotating block a1, the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com