Lightning rod for high-rise buildings

A high-rise building, lightning rod technology, applied in electrical components, circuits, corona discharge devices, etc., can solve the problems of no heat dissipation function, inconvenient installation, poor lightning rod flashing effect, etc., to achieve good and convenient flashing effect. Easy wiring and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

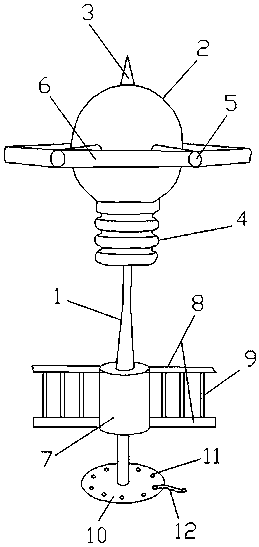

[0013] Such as Figure 1-Figure 2 As shown, a lightning rod for high-rise buildings includes a needle bar 1, a metal ball 2 and a needle tip part 3, an insulator 4 is fixed on the bottom of the metal ball 2, and the insulating character 4 is made of ceramics, and a round hole is provided inside, so that the needle bar 1 The top can go through. The metal ball 2 and the insulator are welded by brazing process, which can keep the surface of the joint clean, good air tightness, stable shape and size, the structure and performance of the weldment do not change much, and the same or different metals and some non-identical parts can be connected. Metal. During brazing, the overall heating of the workpiece can also be used, and many welds can be welded at one time, which improves the productivity. However, the strength of brazed joints is low, and lap joints are mostly used, and the strength of the joints is increased by increasing the length of the lap; in addition, the preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com