Rectifying control system with redundant current feedback

A current feedback and control system technology, applied in the direction of converting AC power input into DC power output, irreversible AC power input into DC power output, electrical components, etc., can solve unit output fluctuations, difficult to improve safety, interference, etc. problems, to achieve the effect of optimizing system security, improving control response speed and overall accuracy, and avoiding abnormal changes in output current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the description of the technical method of the present invention clearer, further elaboration will be made below in conjunction with the accompanying drawings. It should be noted that the accompanying drawings are only used to illustrate the solution, and do not fully represent the entire content of the present invention, nor represent all situations of actual application.

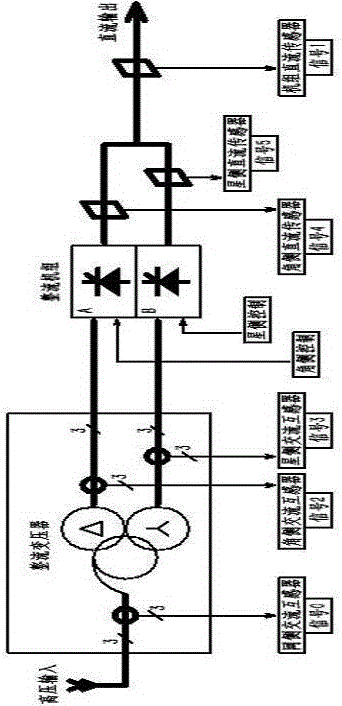

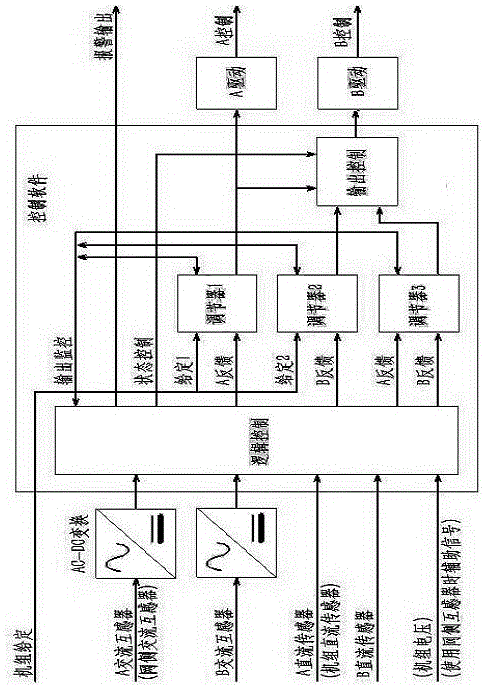

[0028] Such as figure 1 As shown, the large-scale rectification system is divided into several 12-pulse rectifier units based on the number of rectifier transformers, and the unit is divided into two 6-pulse devices, star and corner. The current signals used by the control system as feedback are marked separately in the figure. These relationships exist between the current signals in the system:

[0029] ·There is a linear relationship between the AC current conversion signal of the star-side rectifier device and the DC current measurement signal, but with a small amount of error....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com