Heel board having structuring insert

A technology of heel plate and bottom plate, applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

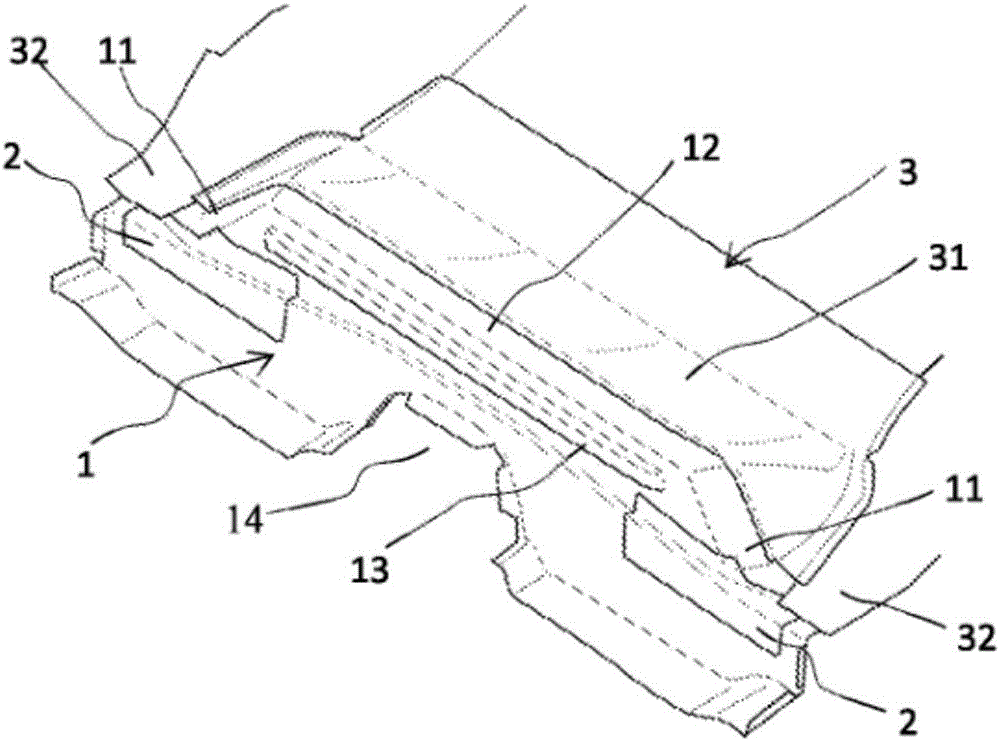

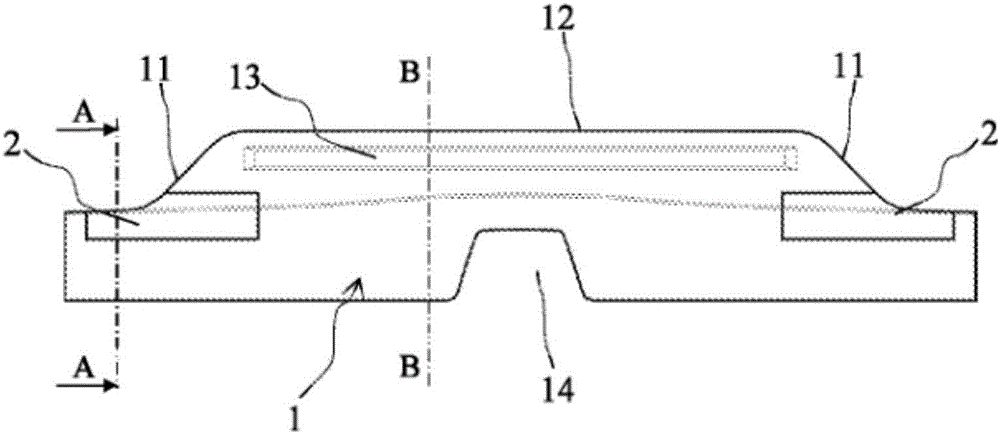

[0030] The accompanying drawings are schematic diagrams to aid in the understanding of the present invention. Components are not necessarily shown to scale. The same reference numbers between the figures correspond to the same components.

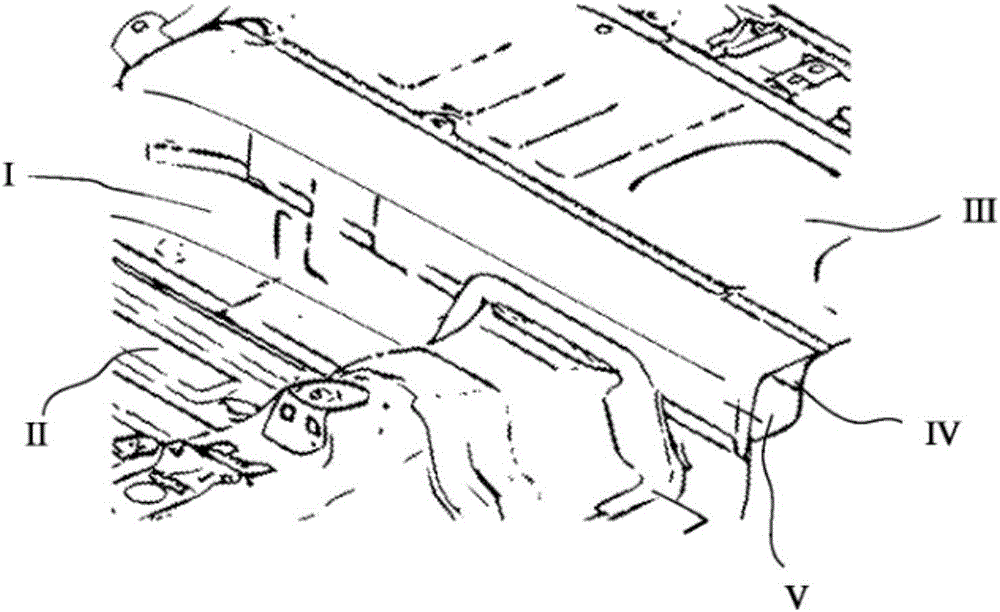

[0031] When the heel plate is mounted on a vehicle, the terms front, rear, upper, lower, sideways are defined with respect to the vehicle. Likewise, the transverse and longitudinal directions correspond to those of the vehicle when the heel plate is secured to the vehicle.

[0032] figure 2 A heel plate 1 equipped with two lateral reinforcements 2 is shown. The heel plate 1 extends between two longitudinal beams, not shown, which are generally located on each side of the vehicle floor.

[0033] Heel plate 1 acts as the front floor ( figure 2 Not shown in ) and the joint between the seat frame bottom plate 3, the seat frame bottom plate 3 is higher than the front bottom plate. The seat frame bottom plate 3 supports one or more seat f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap