Flame-retardant floor material and method for manufacturing same

A technology of floor material and balance layer, applied in the direction of floor covering, chemical instruments and methods, building construction, etc., to achieve the effect of enhancing overall size, excellent flame retardancy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The construction and function of preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

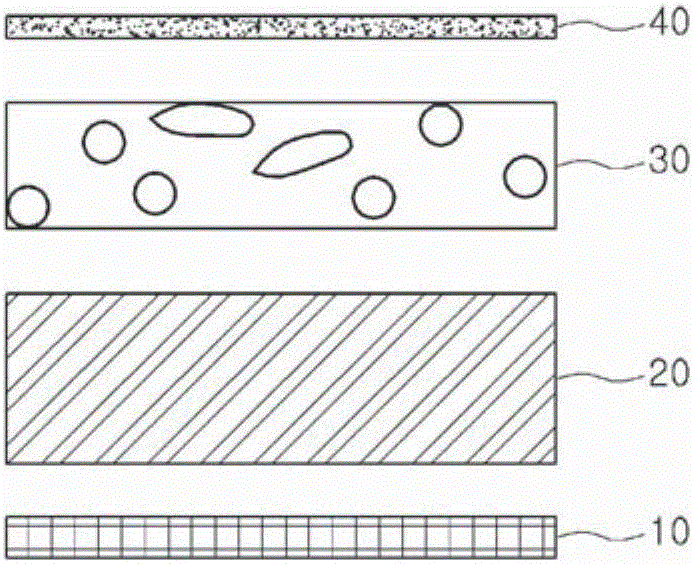

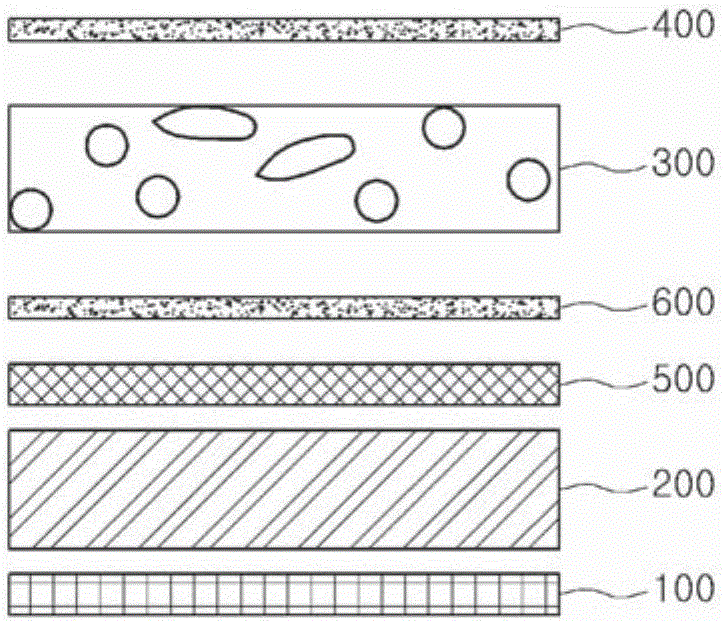

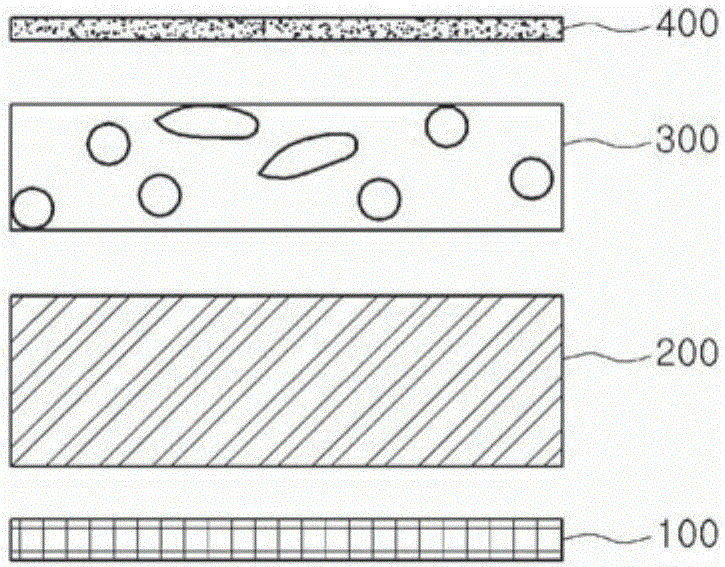

[0037] figure 2 is a cross-sectional view showing the configuration of a flame-retardant flooring material of one embodiment of the present invention, and image 3 is a cross-sectional view showing the configuration of a flame-retardant flooring material according to another embodiment of the present invention.

[0038] refer to figure 2 , the flame retardant flooring material of a preferred embodiment of the present invention comprises: plain weave layer 100; PVB balance layer 200, it is stacked on the upper surface of plain weave layer 100; Size reinforcement layer 500, it uses adhesive to stack on PVB On the upper surface of the balance layer 200; the printing layer 600, which is stacked on the upper surface of the size enhancement layer 500; the transparent PVC layer 300, which is stacked on the upper surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com