Vehicle-mounted cantilever type spherical crown hedge automatic rotor cut molding device

A molding device and cantilever technology, which is applied in the field of automatic rotary cutting and molding devices for spherical crown hedges, can solve the problems of difficulty in completing the spherical crown shape and pruning of plants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

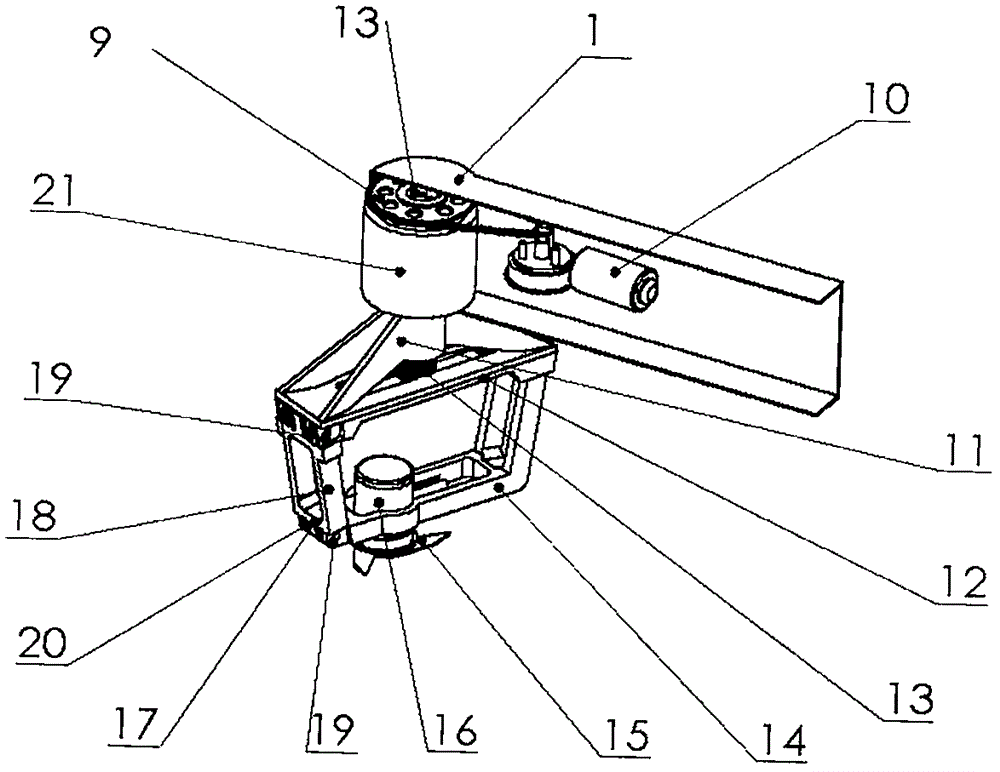

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is further described,

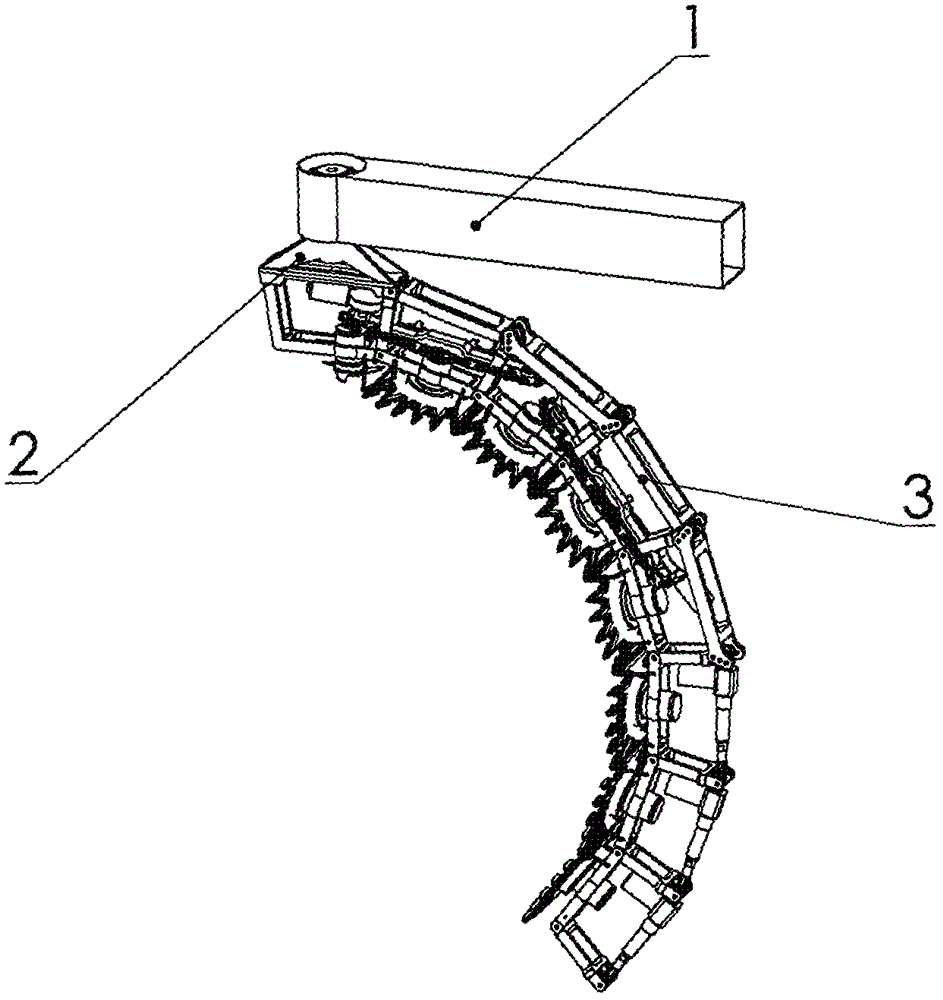

[0026] Such as figure 1 As shown, the present embodiment is a supporting working device for vehicle-mounted or self-propelled hedge trimmers, and requires the carrying vehicle to provide necessary hydraulic stations and DC power supplies, and is equipped with a three-dimensionally controllable cantilever beam (1) to ensure that the cantilever beam (1) The central rotating body (2) of the arc-shaped combined spherical crown header (3) suspended at the end can be aligned with the required height directly above the pre-trimmed spherical crown hedge. The central rotating body (2) installed at the end of the cantilever beam (1) drives the arc-shaped combined spherical crown header (3) to rotate with the vertical main rotating hollow shaft. The arc-shaped combined spherical crown header (3) is a combination of multiple single headers.

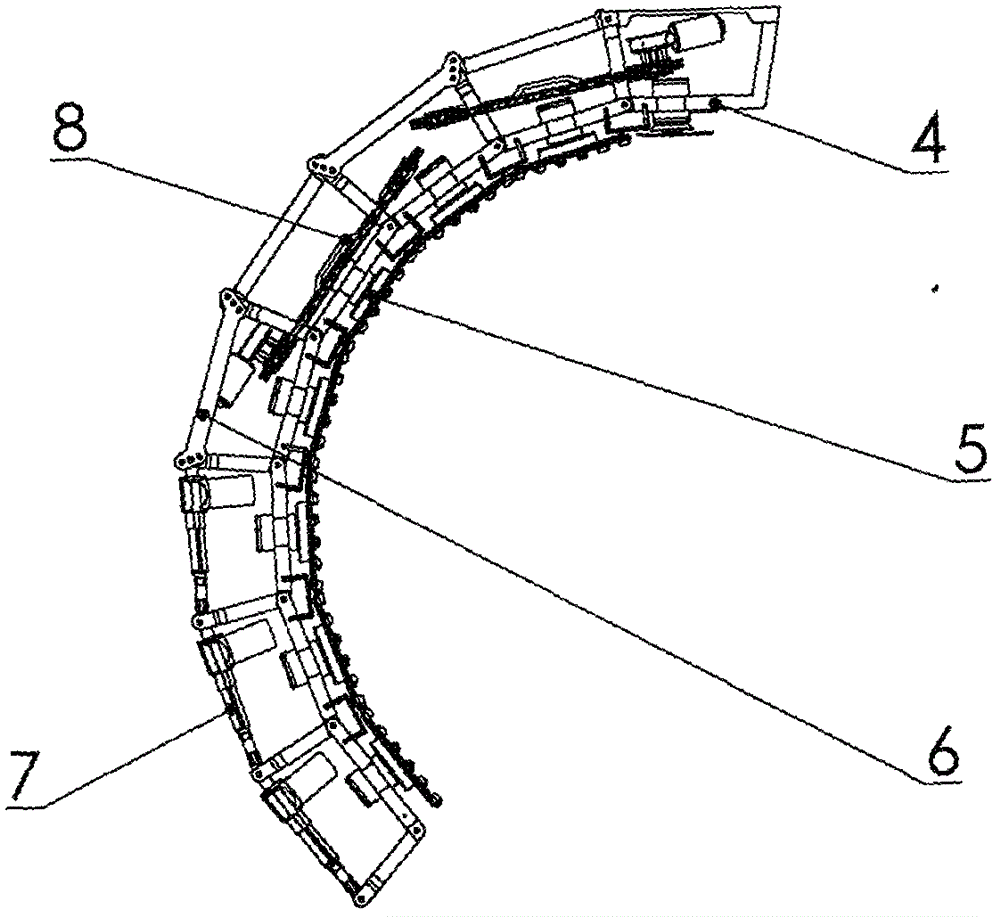

[0027] Such as figure 2As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com