Ink supply system

An ink supply and ink cartridge technology, applied in printing and other directions, can solve the problems of poor reliability and high complexity of the ink supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

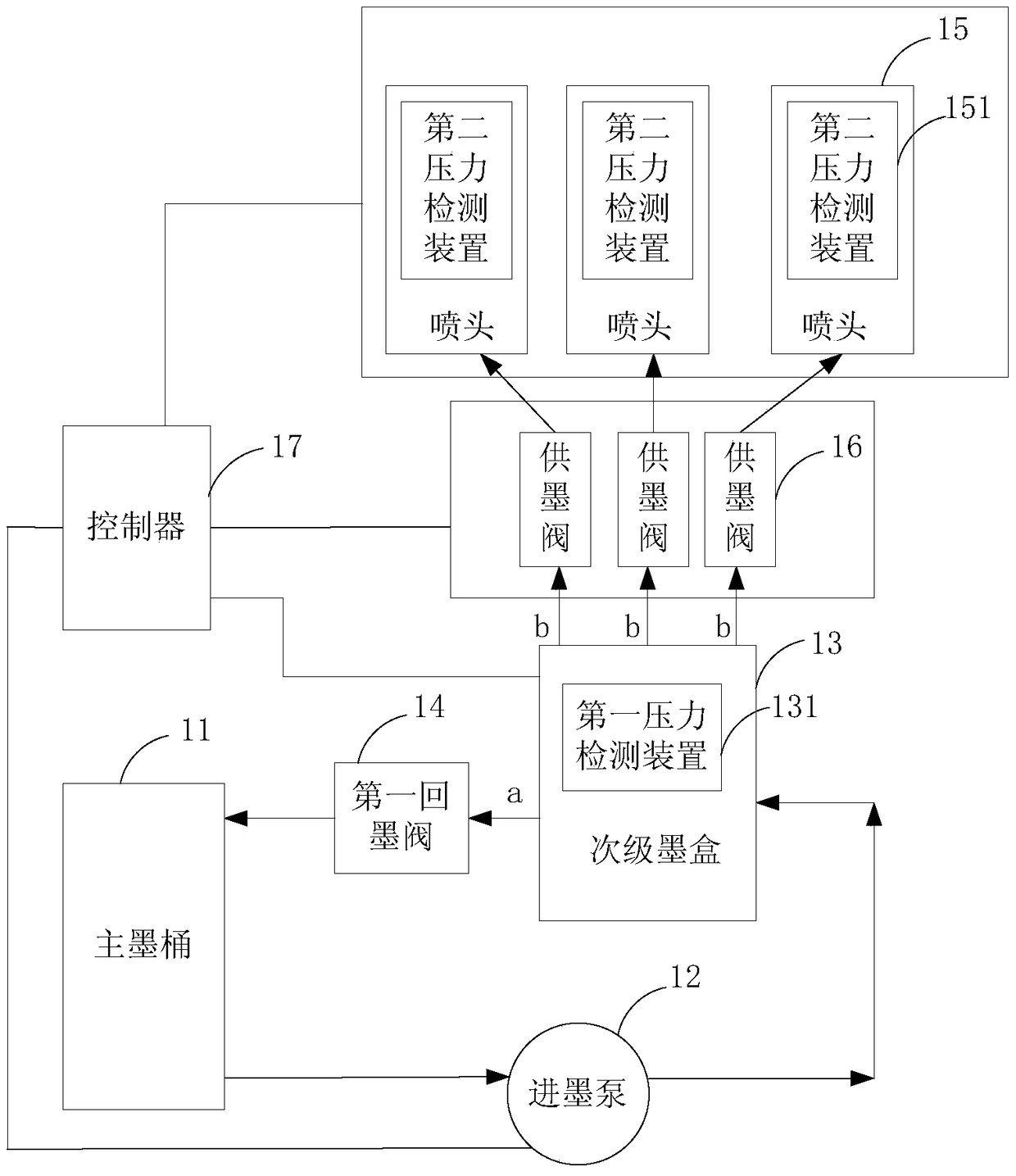

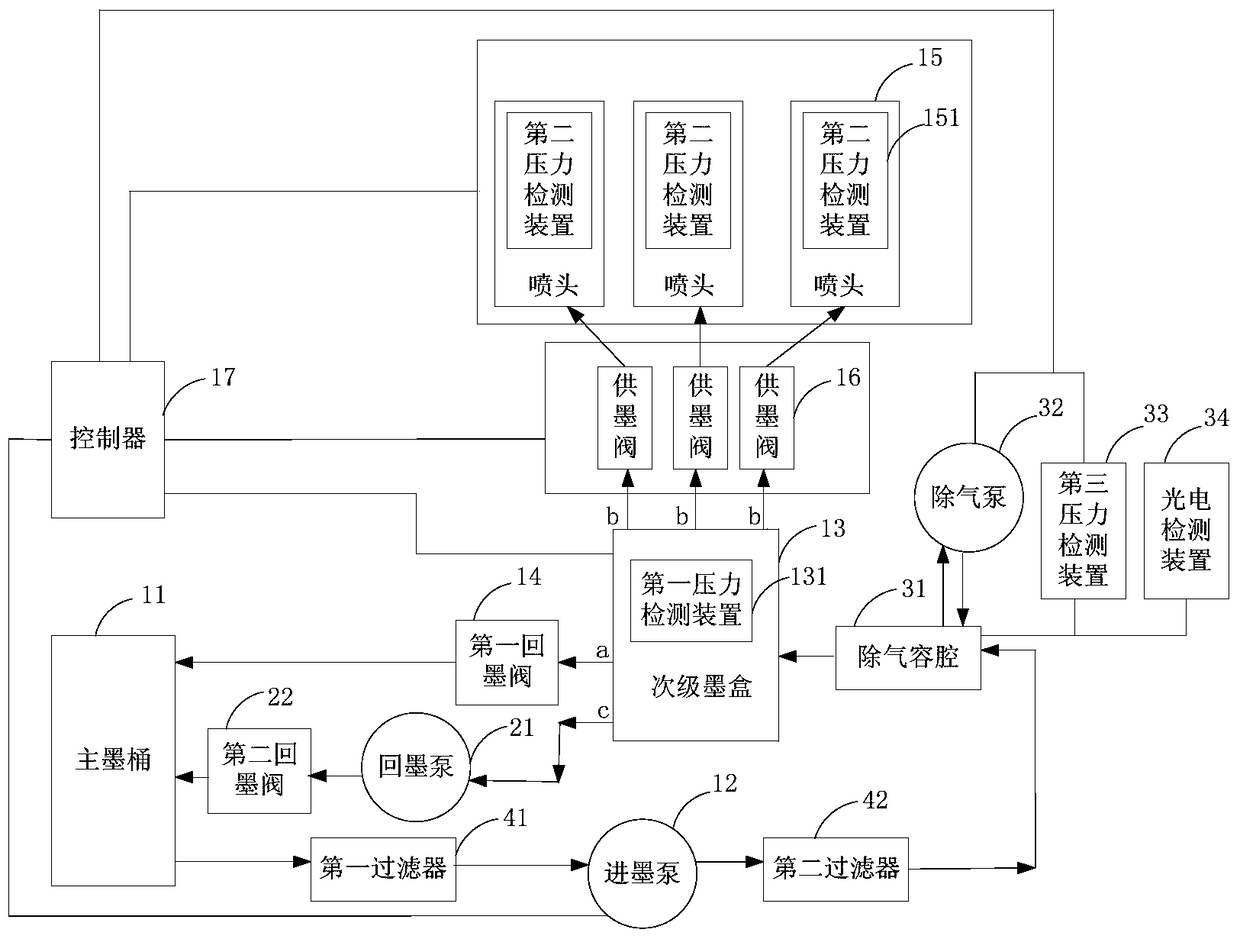

[0015] figure 1 It is a schematic structural diagram of Embodiment 1 of the ink supply system provided by the present invention, and the direction of the arrow in the figure indicates the direction of ink flow. Such as figure 1 As shown, the ink supply system includes:

[0016] Main ink tank 11 , ink inlet pump 12 , secondary ink box 13 , first ink return valve 14 , at least one nozzle 15 , ink supply valve 16 corresponding to each nozzle, and controller 17 .

[0017] The ink outlet of main ink barrel 11 is connected with the ink inlet of ink inlet pump 12, and the ink outlet of ink inlet pump 12 is connected with the ink inlet of secondary ink box 13, and the first ink outlet a of secondary ink box 13 passes through The first ink return valve 14 is connected to the main ink barrel 11 , and each second ink outlet b of the secondary ink box 13 is connected to each nozzle 15 through an ink supply valve 16 corresponding to each nozzle 15 .

[0018] It is worth noting that, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com