Plate type processing machine

A processing machine and plate-type technology, applied in the field of plate processing, can solve the problems of low efficiency of plate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

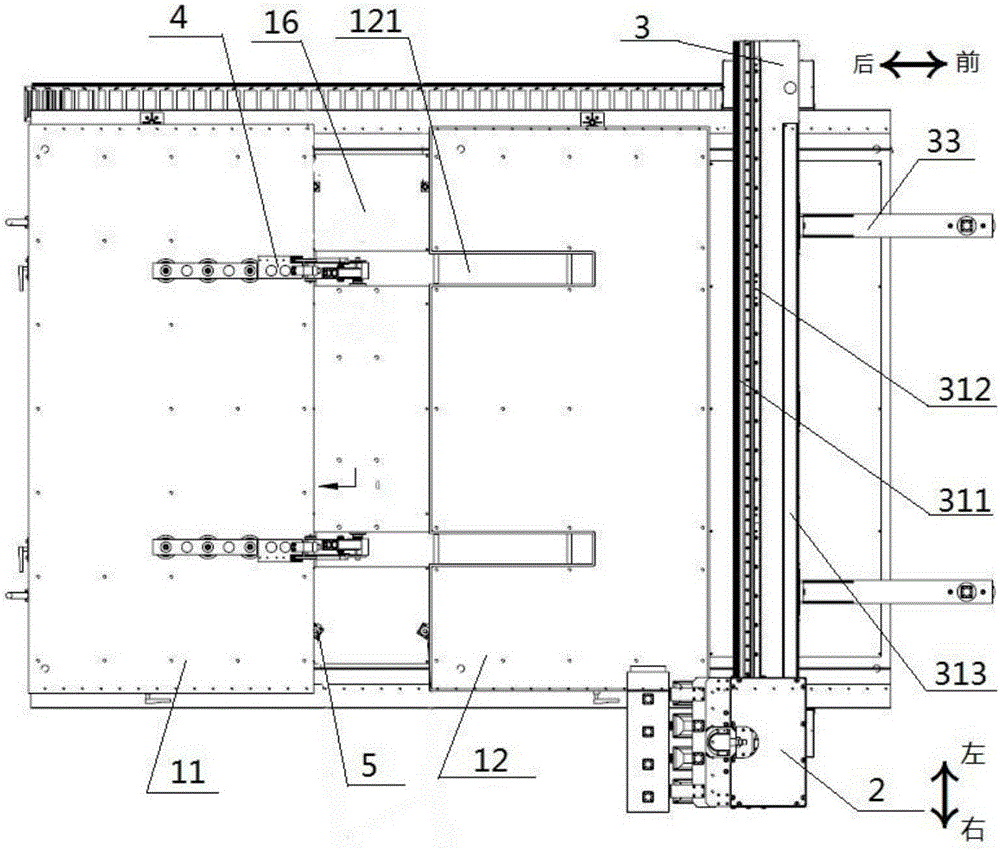

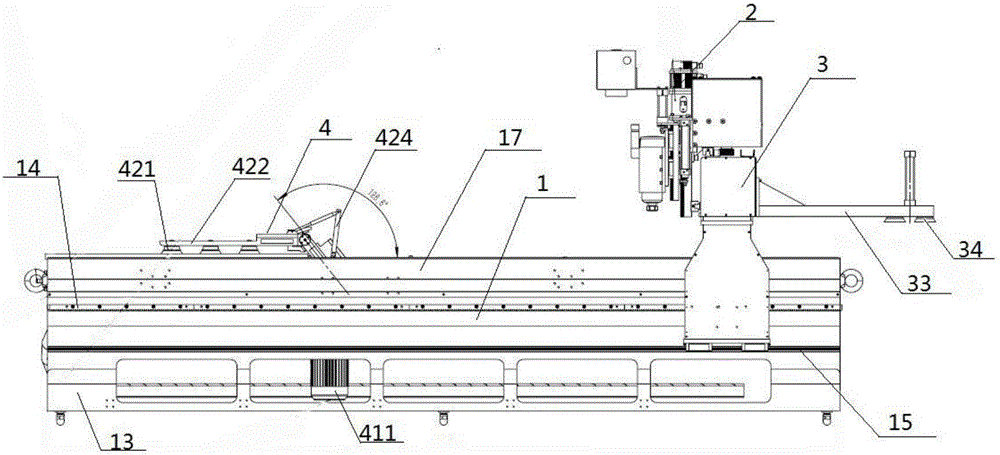

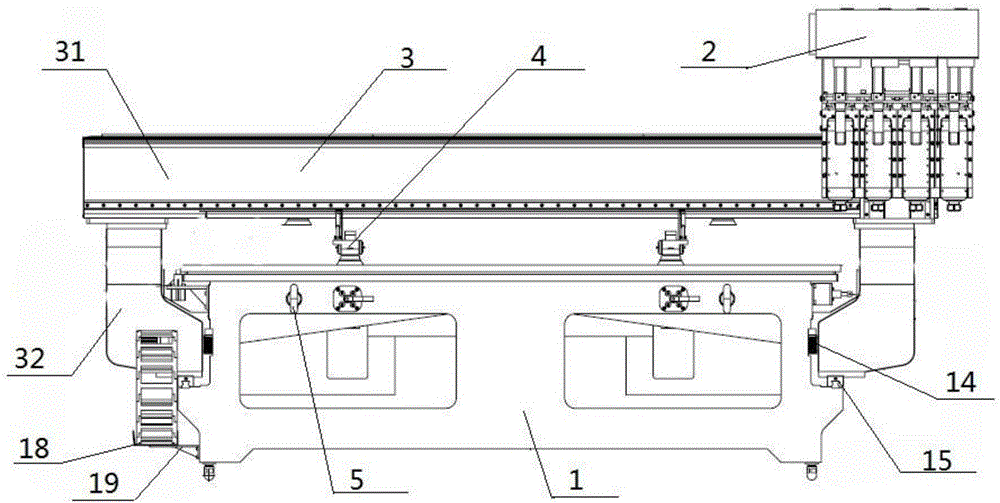

[0034] Refer to attached Figure 1-3 To describe the embodiment of the present application, a plate processing machine includes: a base device 1, a host device 2, a beam device 3 and a plate turning machine 4;

[0035] The host device 2 is arranged on the beam device 3, and a processing head is installed in the host device 2 for processing standard plates; numerical control technology is used to control the movement tracks of the host device 2 and the beam device 3, and the Standard plate processing for different pattern requirements.

[0036] The beam device 3 straddles the base device 1 for supporting the host device 2 and moving the host device 2 to the position where the standard plate needs to be processed.

[0037] The standard board here refers to the board with a certain size, including the unprocessed board, the processed board or the processed board.

[0038] Specifically, the beam device 3 is controlled by a forward and backward moving drive source, such as a serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com