Ring Chilled Iron Lifting Tool

A hoisting tool and a ring-shaped technology, applied in the field of spreaders, can solve problems such as unfavorable production efficiency, production process safety, impact on the service life of cold iron, and slow down the production efficiency of rolls, so as to achieve convenient and efficient hoisting, prolong service life, and improve reliability. operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail:

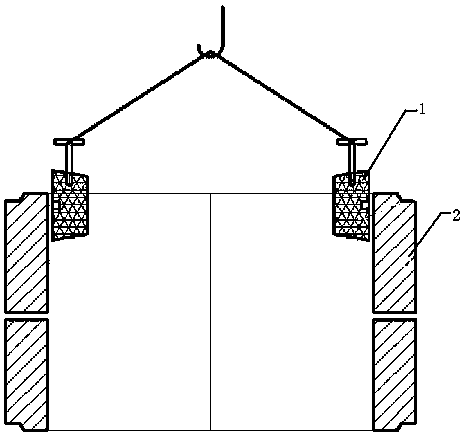

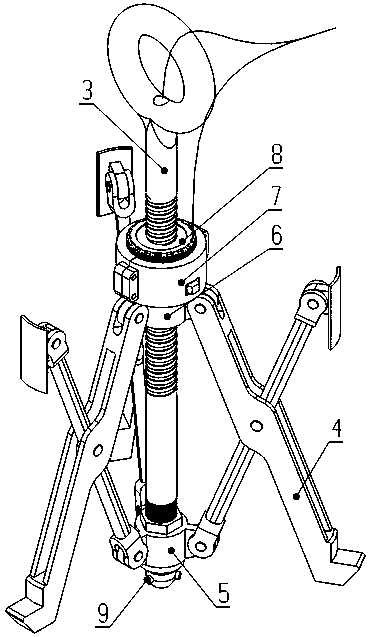

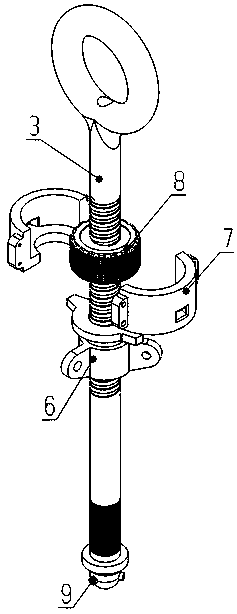

[0028] Such as figure 2 Shown is the structural representation of the present invention. The present invention is a novel spreader specially used for hoisting ring-shaped cold iron 1, mainly comprising a lifting rod 3 and three to five X-shaped brackets installed around the lifting rod 3. Each X-shaped bracket 4 is composed of a load-bearing bar 401 and a support bar 402 hinged to each other in the middle. The upper end of the lifting rod 3 is provided with a hoisting ring hooked with the hook of the crane, and a circle of X-shaped supports 4 is uniformly installed below the hoisting ring, and the number of X-shaped supports 4 is preferably three in the present embodiment.

[0029] The lifting rod 3 is hinged by a support rod mounting plate 5 and the lower end of the support rod 402 . Specifically, the lower end of the lifting rod 3 is provided with a flange-type boss, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap