Demoulding structure of steel casing for bored pile at deepwater area

A technology of bored piles and steel casings, which is used in infrastructure engineering, sheet pile walls, buildings, etc., can solve problems such as heavy weight, groundwater pollution, and inability to achieve lifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

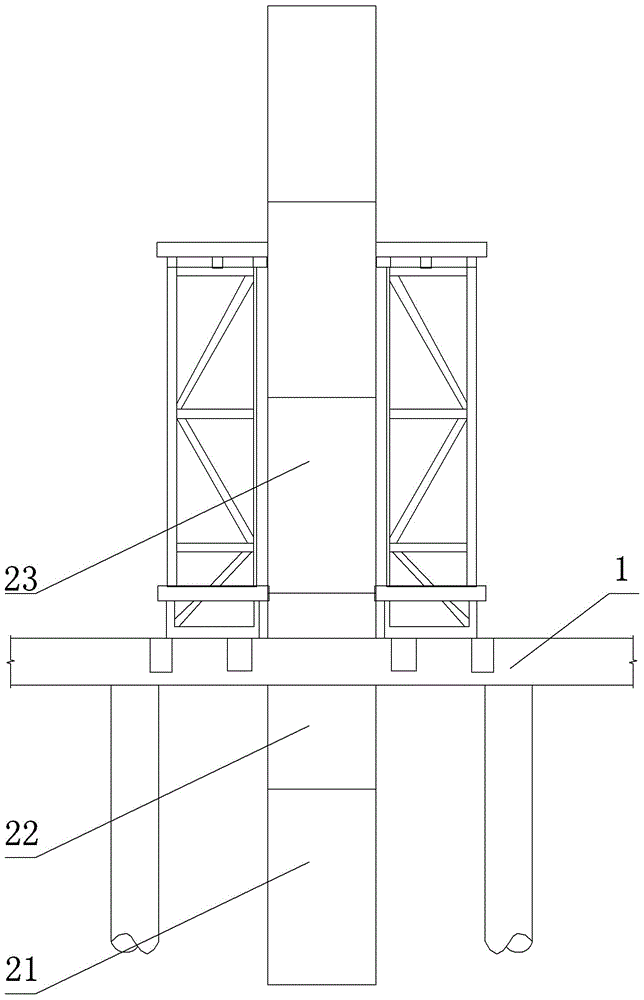

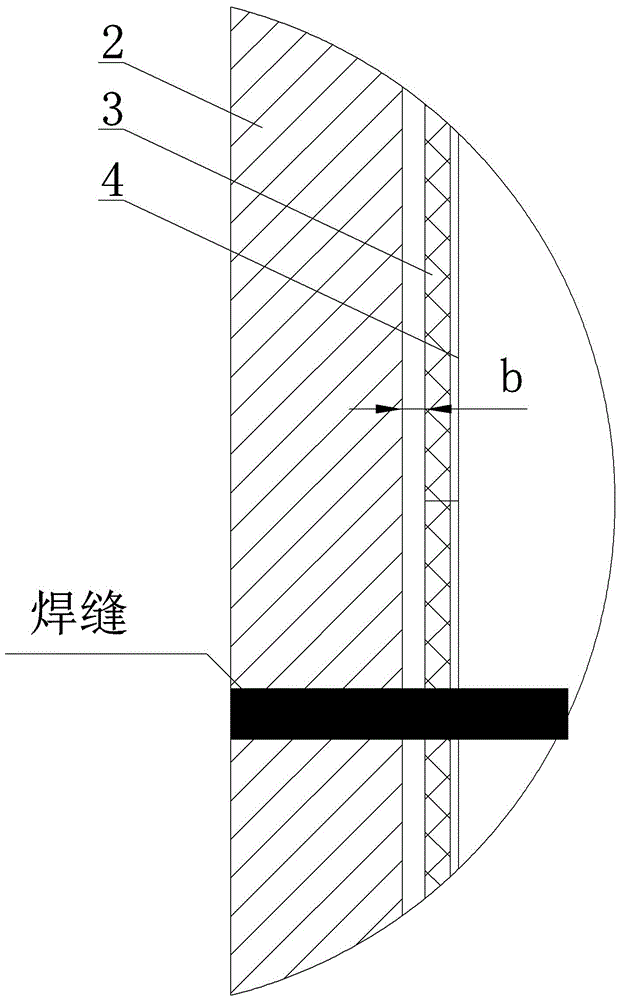

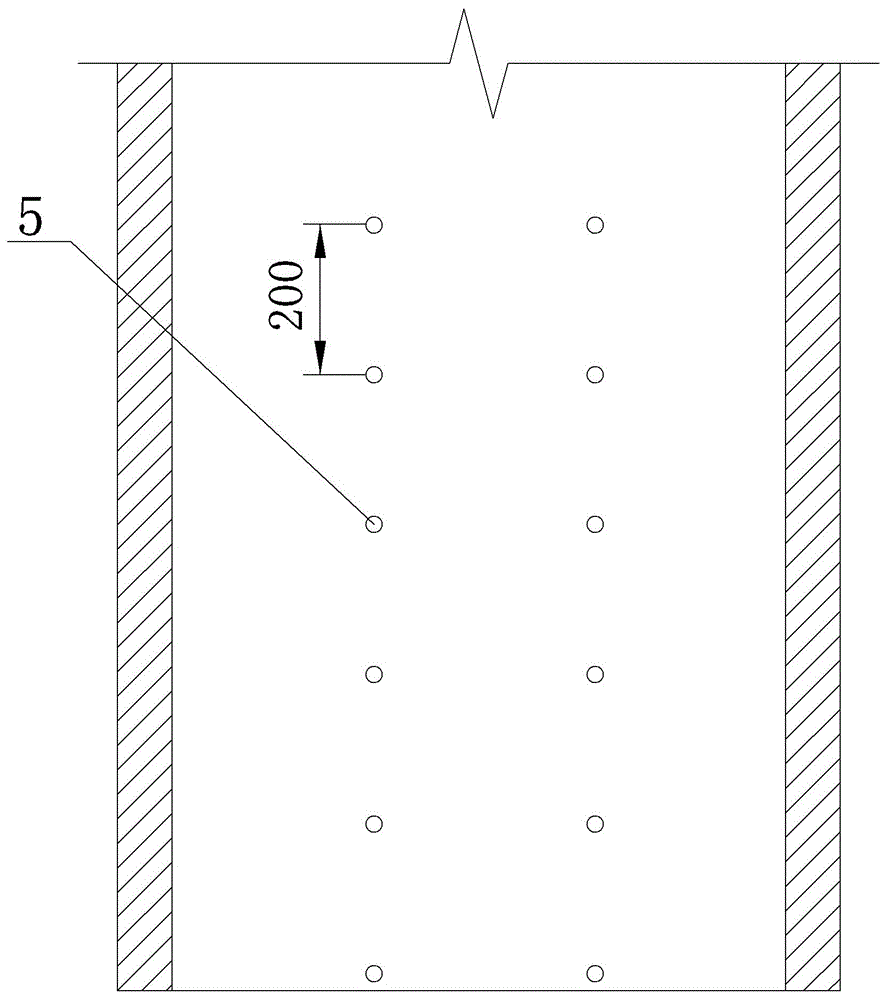

[0019] The reference signs in the accompanying drawings of the specification include: drilling platform 1, steel casing 2, wooden formwork 3, film 4, thumbtack 5, first section steel casing 21, second section steel casing 22, third section steel casing Casing 23.

[0020] The embodiment is basically as figure 1 , figure 2 and image 3 Shown: When constructing in deep water area, not only the steel casing 2 needs to be soaked in water all the time, but also the inner wall of the steel casing 2 will rub against the silt when it enters the silt layer in the seabed or river bed, while the conventional detachment The mold agent cannot adapt to such an environment, because it is difficult for the conventional mold release agent to ensure that there is no dew point underwater, and the conventional mold release agent is easily diluted underwater, resulting in the steel casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com