A hot gas defrosting method, hot gas defrosting and refrigeration cycle method

A hot gas, high temperature gas technology, applied in hot gas defrosting and refrigeration cycle, hot gas defrosting field, can solve the problems of liquid explosion, high energy consumption, poor defrosting effect, etc., to ensure the safety and reliability of use, improve the defrosting effect. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

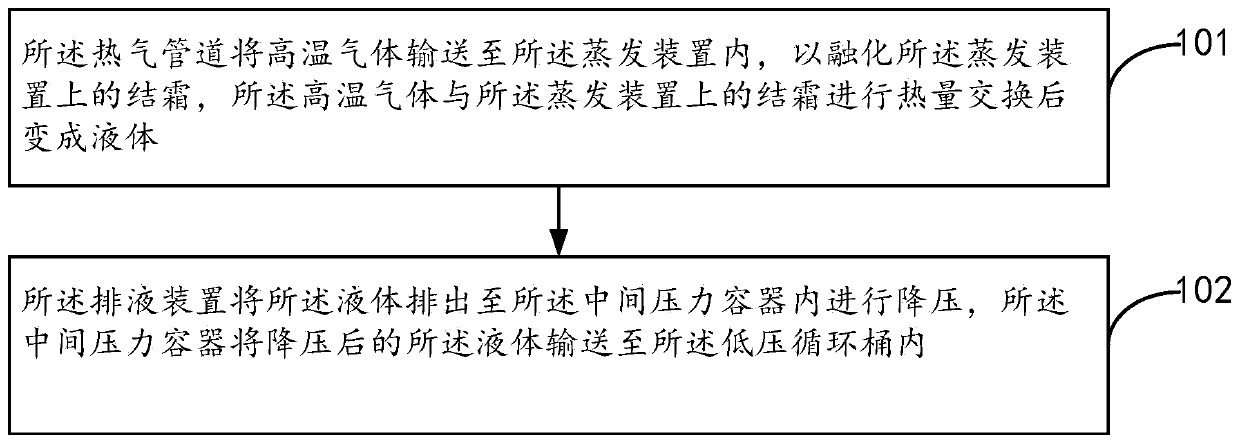

[0053] see figure 1 , is a flow chart of the hot gas defrosting method provided in Embodiment 1 of the present invention. in, figure 1 The described hot gas defrosting method can be applied to a hot gas defrosting system, and the hot gas defrosting system may include a hot gas pipeline, an evaporating device, a liquid draining device, an intermediate pressure vessel and a low-pressure circulation bucket connected in sequence. Such as figure 1 As shown, the hot gas defrosting method may include the following operations:

[0054] 101. The hot gas pipeline transports the high-temperature gas to the evaporator to melt the frost on the evaporator. The above-mentioned high-temperature gas exchanges heat with the frost on the evaporator and becomes liquid.

[0055] In the embodiment of the present invention, the hot gas pipeline is also provided with a hot gas solenoid valve, the hot gas solenoid valve is electrically connected to an external control device, the startup time of th...

Embodiment 2

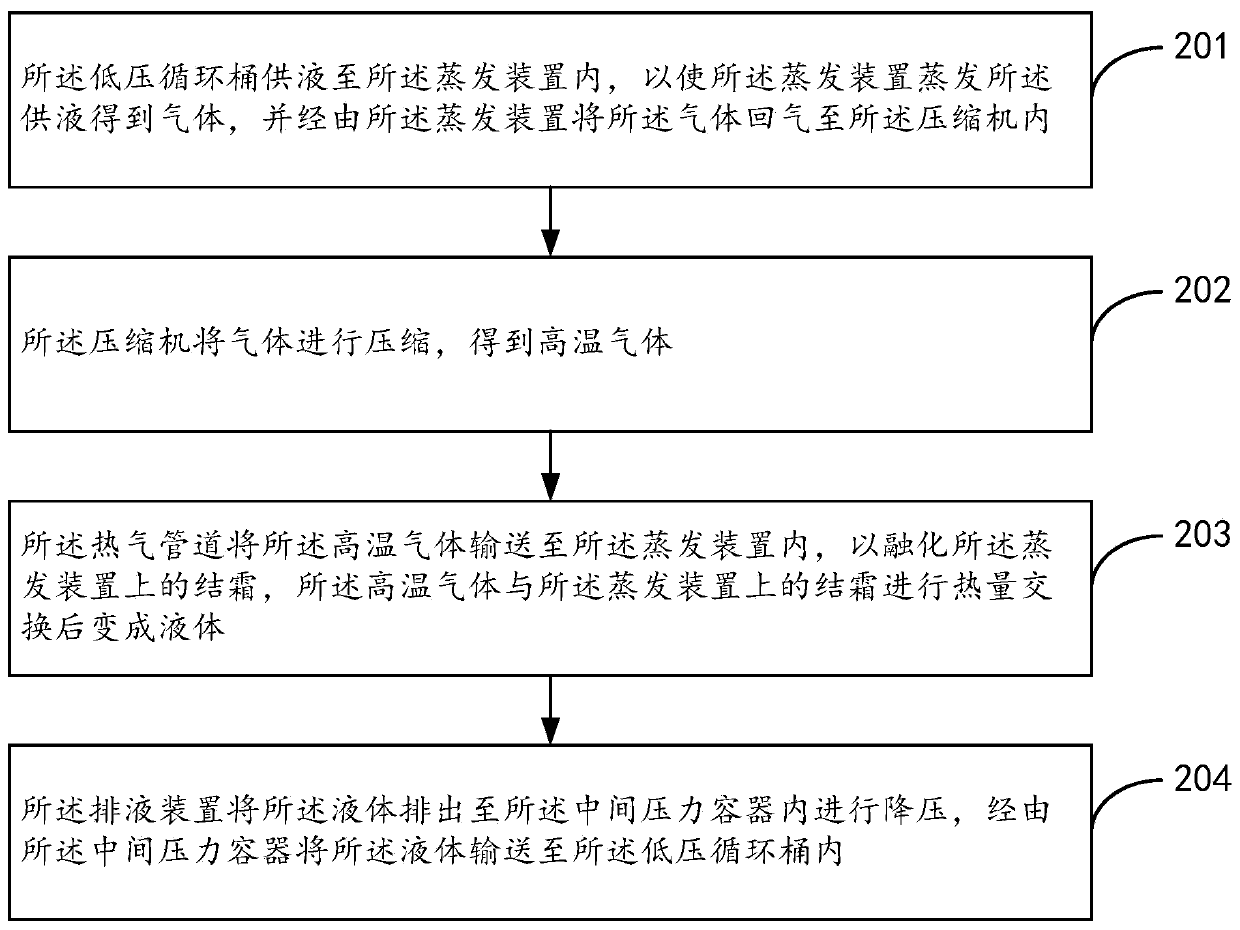

[0067] See figure 2 , is a flowchart of a hot gas defrosting and refrigeration cycle method disclosed in Embodiment 2 of the present invention. in, figure 2 The described hot gas defrosting and refrigeration cycle method can be applied in a hot gas defrosting and refrigeration cycle system, and the hot gas defrosting and refrigeration cycle system may include a hot gas pipeline, an evaporating device, a liquid discharge device, an intermediate pressure vessel, a low-pressure circulation barrel and compressor. Such as figure 1 As shown, the hot gas defrosting and refrigeration cycle method may include the following operations:

[0068] 201. The low-pressure circulation barrel supplies liquid to the evaporating device, so that the evaporating device evaporates the above-mentioned supplied liquid to obtain gas, and returns the gas to the compressor through the evaporating device.

[0069] 202. The compressor compresses the gas to obtain high-temperature gas.

[0070] 203. ...

Embodiment 3

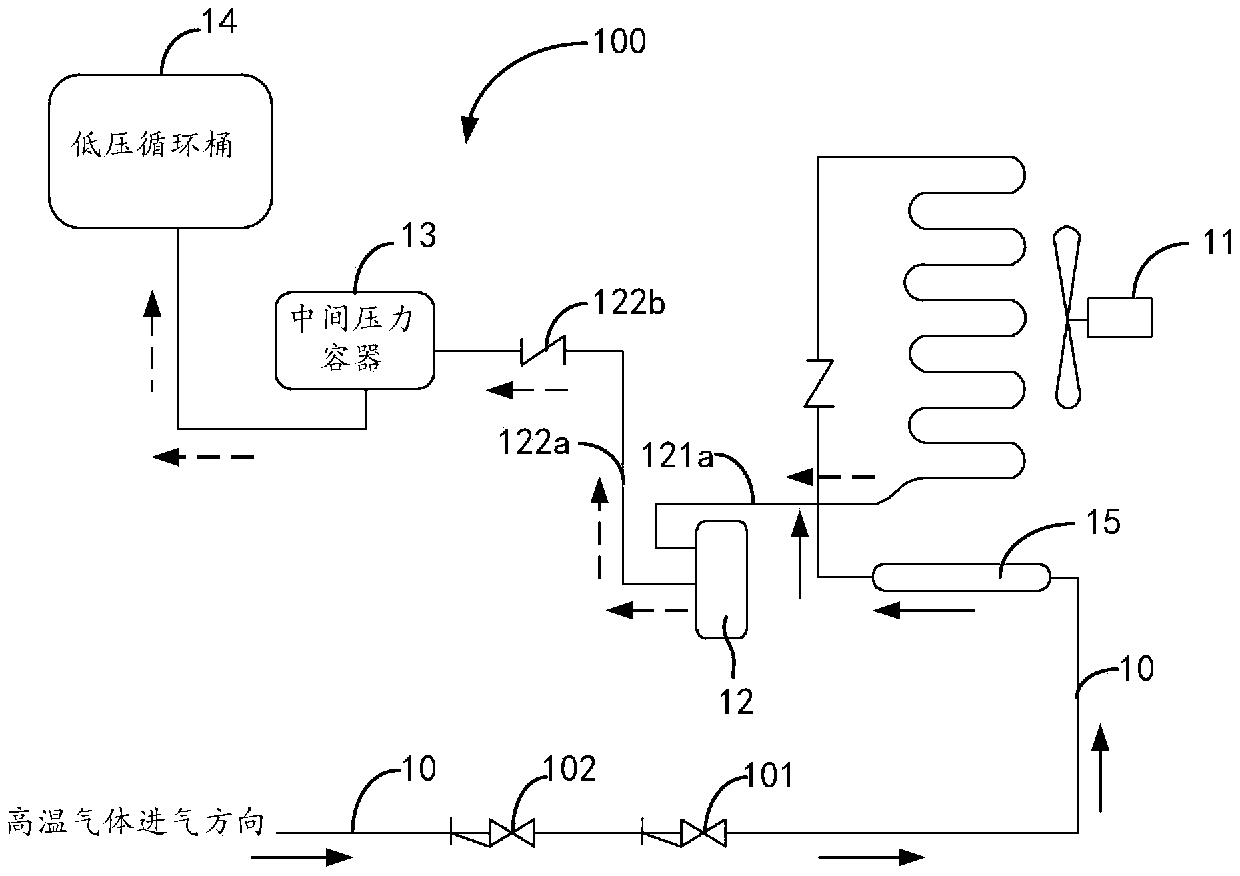

[0082] see image 3 , is a schematic structural diagram of the hot gas defrosting system 100 provided in Embodiment 3 of the present invention. A hot gas defrosting system 100 provided in Embodiment 3 of the present invention includes a hot gas pipeline 10, an evaporation device 11, a liquid discharge device 12, an intermediate pressure vessel 13, and a low-pressure circulation barrel 14. The hot gas pipeline 10 is used to feed high-temperature gas (not marked), the evaporation device 11 has a high-temperature gas inlet (not marked), and the high-temperature gas inlet is connected to the hot gas pipeline 10 . The liquid discharge device 12 is connected to the liquid outlet of the evaporator 11 (not marked), the intermediate pressure vessel 13 is connected to the liquid discharge device 12 to receive the liquid discharged from the liquid discharge device 12, and the low-pressure circulation barrel 14 is connected to the intermediate pressure vessel 13. The hot gas pipeline 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com