Button structure assembly

A key and assembly technology, applied in the field of structural improvement design, can solve the problems of unfavorable industrial utilization value, practicability and durability not as good as mechanical keys, poor key sensitivity, etc., to achieve high industrial utilization value, excellent waterproof and dustproof. Effect, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in combination with specific embodiments and accompanying drawings, and the advantages and characteristics of the present invention will become clearer along with the description.

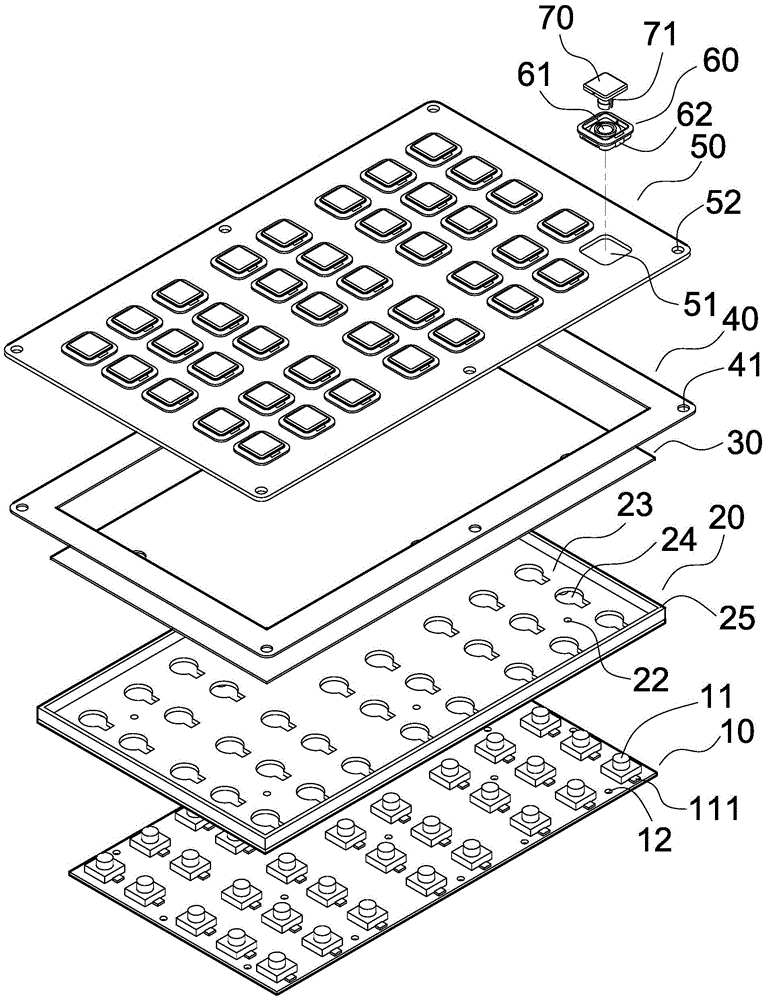

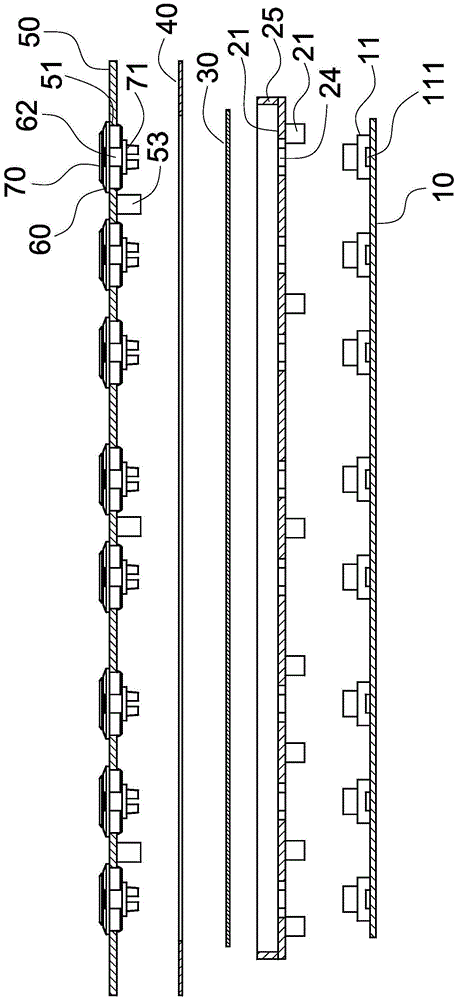

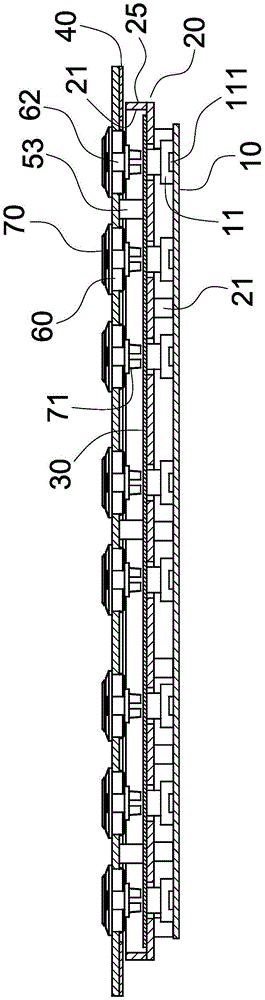

[0045] Such as Figure 1 to Figure 9A As shown, the preferred implementation mode of the present invention is illustrated. As shown in the figure, the button structure assembly of the present invention mainly includes: a circuit board 10, a back cover plate 20, a silicone gasket 30, and a waterproof pad A sheet 40, a surface plate 50 and a plurality of button bases 60 and buttons 70 are formed.

[0046]Its surface of this circuit board 10 is planned with button circuit (not shown in the figure), and is arranged with predetermined number of key bodies 11 on its top surface planning, and its side of each key body 11 also includes illuminant 111 (generally LED ), there are a plurality of circuit board bolt holes 12 by default at predetermin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com