Three-color key injection molding technology

A button and process technology, which is applied in the field of three-color button injection molding technology, can solve the problems of weak bonding between the second color and the third color, lack of market competitive advantages, and gaps in the fusion of plastic melts, etc., to achieve the elimination of product Internal stress, avoiding unstable assembly quality, and preventing product cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

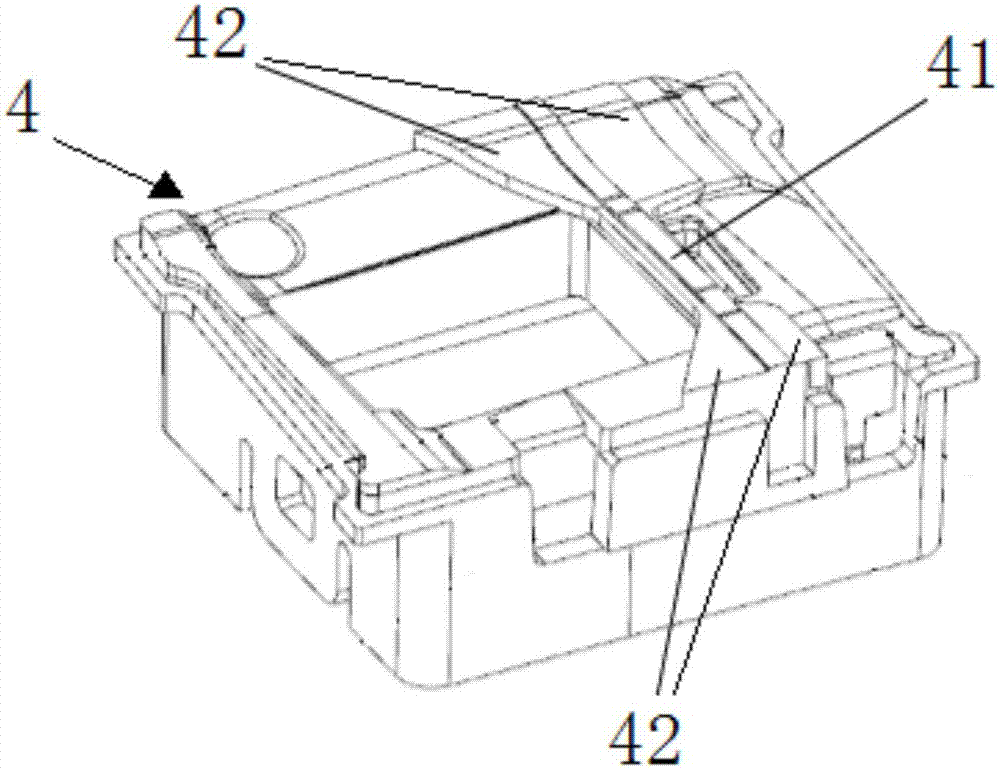

[0041] see Figure 1-4 , a three-color button injection molding process, the steps are as follows:

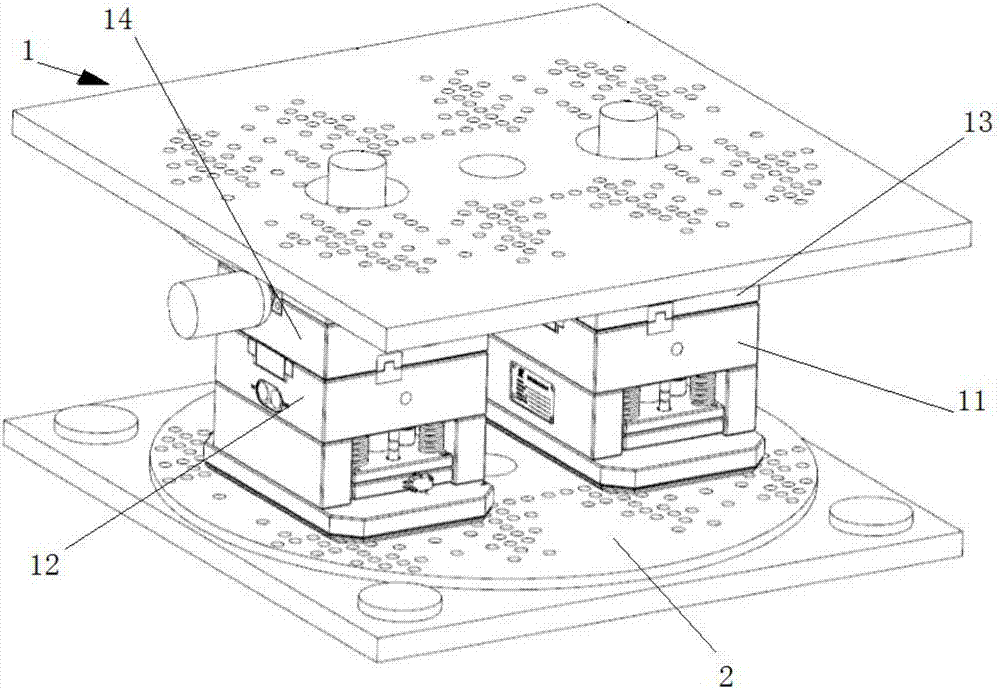

[0042] S1: Mold opening for the first time: using a press and mold 1, said mold 1 includes two identical first rear molds 11 and second rear molds 12 and two different first front molds 13 and second front molds 14. The first rear mold 11 and the second rear mold 12 are center-symmetrically arranged on a turntable 2, the first front mold 13 and the second front mold 14 can move up and down, and the press is used to provide pressure;

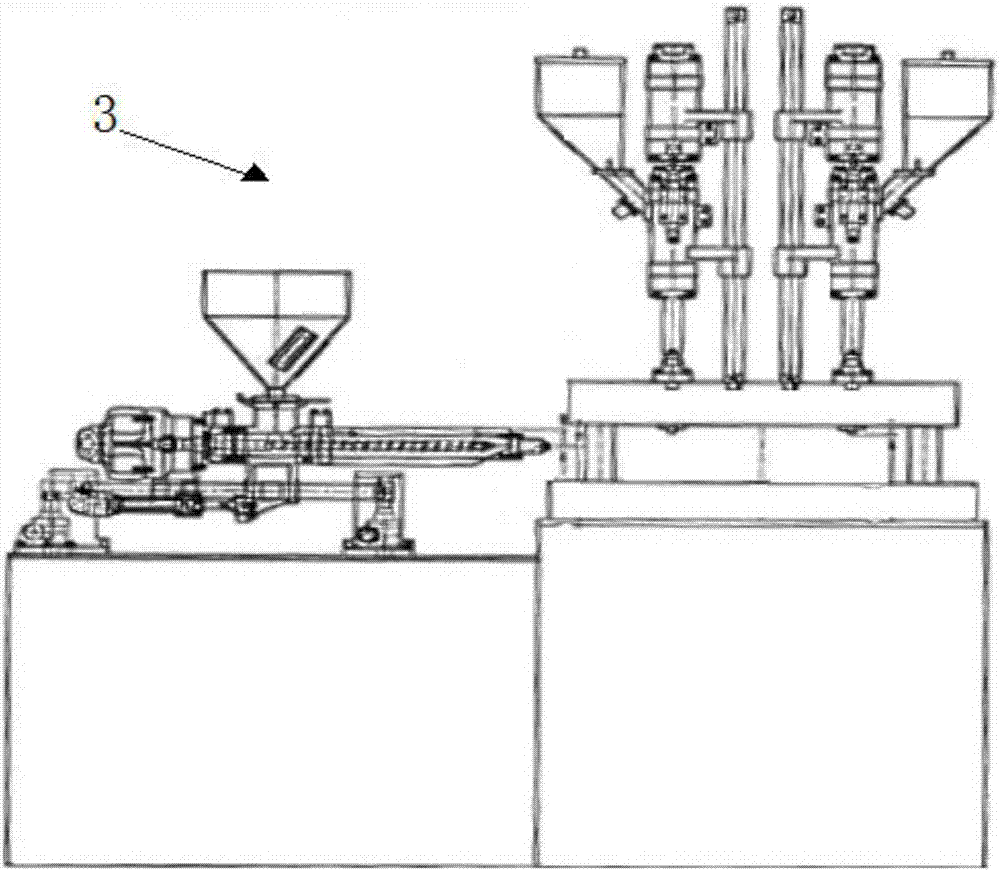

[0043] S2: Mold installation: install the mold 1 above on the three-color injection molding machine 3; the first color of the three-color injection molding machine 3 adopts a three-plate mold with a fine nozzle to inject glue at the gate, and the second color and the third color use The point gate of the three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com