Formwork of cast-in-place fair-faced concrete fire barrier

A technology of fair-faced concrete and fire walls, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., and can solve problems such as water on the concrete surface, grout leakage, and lax joints of formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

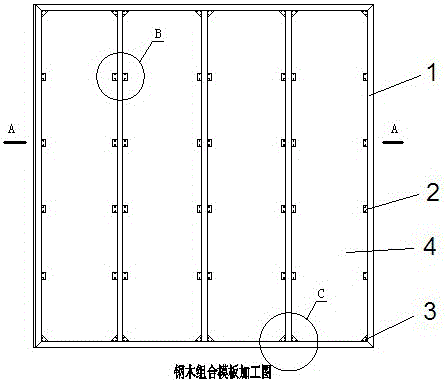

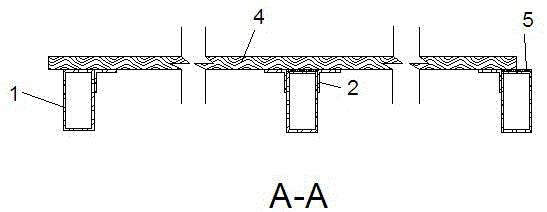

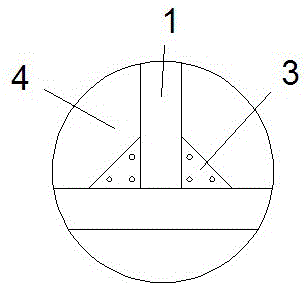

[0011] In order to overcome the defects of wet water, slurry leakage and wrong platform existing in the prior art, the present invention adopts such as Figure 1-5 The technical scheme shown is composed of four square steels 1 forming a frame, and the four corners of the frame are provided with triangular connecting plates 3, and three vertical square steels are evenly distributed in the frame, and the The left and right sides of the two ends of the three vertical square steels are respectively provided with a triangular connecting plate, which is integrated with the vertical square steel and the horizontal square steel. Four angle steels 2 are evenly distributed on the inside of the left and right sides of the left and right sides of the frame and the vertical square steels on the left and right sides of the square frame, the vertical plate of the angle steel is connected with the vertical square steel, and the vertical plate of the angle steel is connected with the vertical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com