Pipe string and completion method

A pipe string and tubing technology, which is applied in the field of oilfield development, can solve problems such as low work efficiency, and achieve the effect of improving work efficiency and saving operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

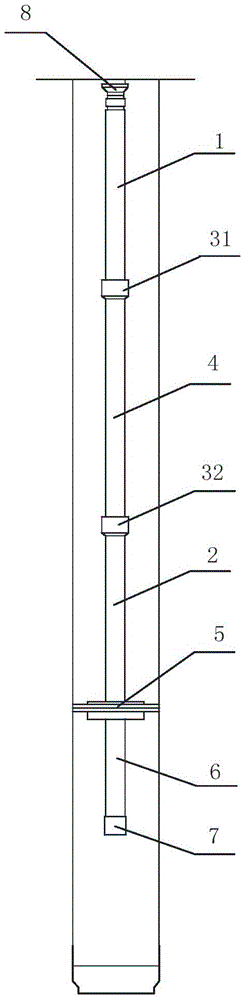

[0054] figure 1 It is a schematic structural diagram of Embodiment 1 of the column provided by the present invention. Refer to attached figure 1 As shown, this embodiment provides a pipe string, and the pipe string in this embodiment can be applied to oil testing and completion operations in Silurian sandstone reservoir blocks.

[0055] A tubing string, including a first oil pipe 1, a second oil pipe 2, a packer 5, and a third oil pipe 6 arranged from top to bottom, and the first oil pipe 1 and the second oil pipe 2 are provided with Gas lift valve.

[0056] Wherein, the first oil pipe 1 is located in the casing in the oil well. The packer 5 is used for setting at the bottom end of the casing section in the oil well. The gas lift valve is openable under gas pressure in the annulus region of the casing section in the oil well to allow gas to enter the gas lift valve from the side of the gas lift valve.

[0057] There are at least two gas lift valves, which are spaced up an...

Embodiment 2

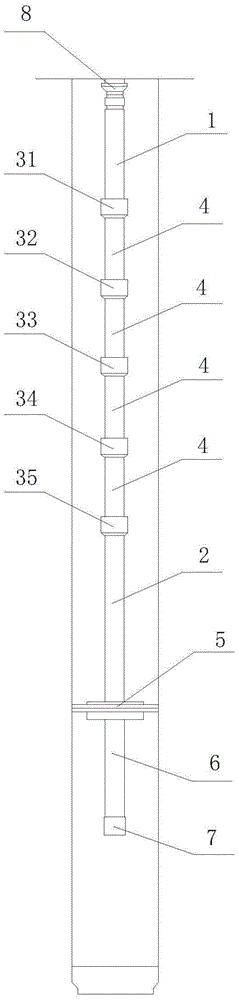

[0072] figure 2 It is a schematic structural diagram of the second embodiment of the column provided by the present invention. Refer to attached figure 2 As shown, the difference between this embodiment and Embodiment 1 is that there are five gas lift valves in this embodiment, which are the primary gas lift valve 31, the secondary gas lift valve 32, the Three-stage gas lift valve 33 , four-stage gas lift valve 34 and five-stage gas lift valve 35 .

[0073] Adjacent gas lift valves are communicated through a fourth oil pipe 4, and there are four fourth oil pipes 4 in this embodiment. Specifically, the top of the primary gas lift valve 31 communicates with the bottom end of the first oil pipe 1, and the bottom end of the primary gas lift valve 31 communicates with the top end of the secondary gas lift valve 32 through a fourth oil pipe 4. The bottom end of the stage gas lift valve 32 communicates with the top of the three stage gas lift valve 33 through a fourth oil pipe 4...

Embodiment 3

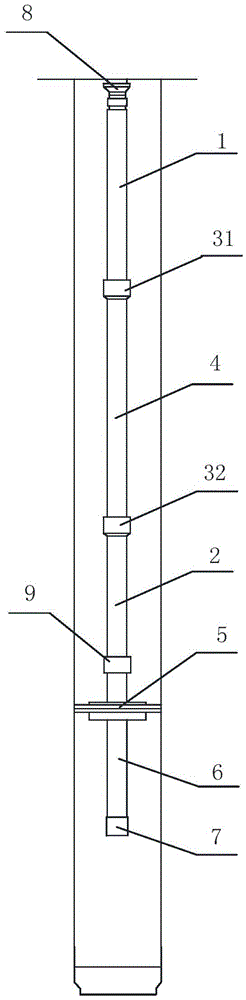

[0078] During the acid fracturing or acidizing process and subsequent oil recovery process, due to the influence of temperature changes and tubing swelling, the second tubing will be stretched or shortened due to force, and because the second tubing is connected to the packer, it is easy to cause isolation The setting seal of the device is not tight enough, and even causes abnormal unsealing, which leads to job failure.

[0079] Therefore, in order to solve the above problems, on the basis of any of the above embodiments, this embodiment provides a pipe string, referring to the attached image 3 as shown, image 3 Schematic diagram of the structure of the pipe string provided in this embodiment.

[0080] The difference between this embodiment and the above-mentioned embodiments is that a telescopic pipe 9 is added in the middle of the second oil pipe 2 .

[0081] That is, a telescopic tube 9 is connected between the top end and the bottom end of the second oil pipe 2 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com