Locating pin

A positioning pin and pin body technology, applied in the field of positioning parts, can solve the problems of easy bumping, poor positioning quality, instability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

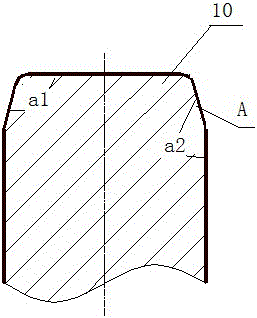

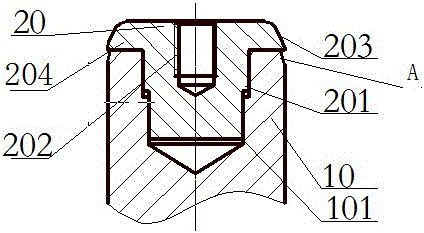

[0018] see figure 2 , The positioning pin of the present invention includes a pin body 10 made of metal material, and on the top of the pin body 10 is provided a guide portion A that is narrow at the top and wide at the bottom. Depend on figure 2 It can be seen that the present invention also includes a protective body 20 made of a softer elastic material. The protective body 20 includes a connecting portion 201 and extends radially outward from the top of the connecting portion 201 and has a maximum outer diameter smaller than or equal to the pin body. The maximum outer diameter of 10, the protective portion 204 whose lower surface fits the top of the pin body 10, the top of the pin body 10 is provided with a connecting blind hole 101 extending longitudinally downward, the connecting portion of the protective body 20 201 is interference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com