Pointer and rotor flowmeter

A rotameter and pointer technology, which is applied to the volume/mass flow generated by mechanical effects, and through the detection of dynamic effects of fluid flow, etc., can solve the problems of the frequency and amplitude of pointer swings, and achieve improved reading accuracy and pointer Indicates a steady, amplitude-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

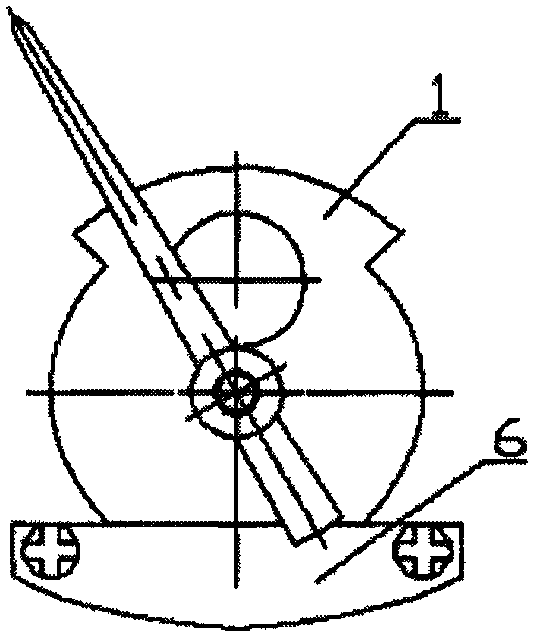

[0007] The present invention includes a tapered tube that gradually expands from bottom to top, a rotor that is placed in the tapered tube and can move freely up and down along the center line of the tube, and a pointer assembly 7 consisting of a pointer, a pointer pressing piece, a pointer seat, and a counterweight 1 , the damping device 6 is installed under the dial of the pointer and is integrated with the dial. The damping device includes a frame composed of two metal plates 4 and a connecting piece 5 and a magnetic steel 2 sucked inside the two metal plates. Two pieces There are gaps 3 between the magnetic steels inside the metal plates to form a closed magnetic field, the counterweight 1 in the pointer assembly can swing freely in this gap, and the number of magnetic steels on each metal plate can be arranged side by side according to needs. The range of the dial is 100-300, and the pointer assembly is made of iron alloy material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com