Pipe file management method and system

A file management method and pipe material technology, which is applied in the field of data application in the chemical industry, can solve the problems of high error rate and low efficiency of manual analysis of pipeline data, and achieve the effects of high degree of automation, convenience for big data analysis, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

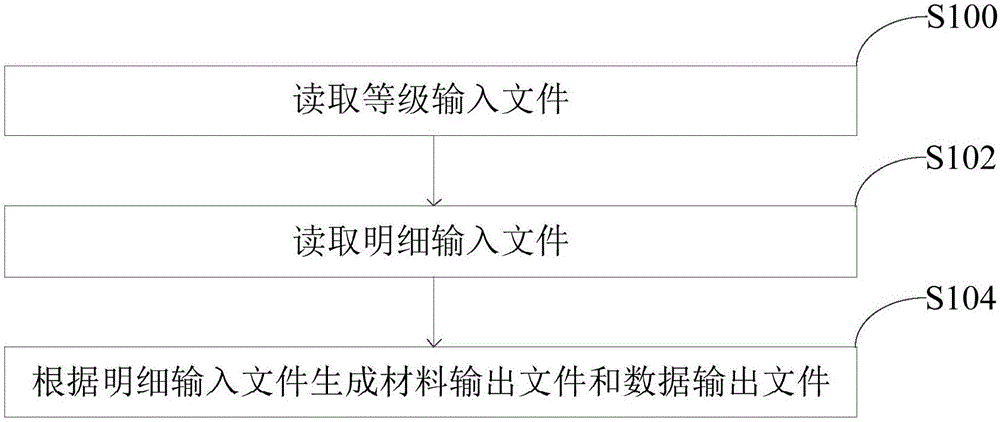

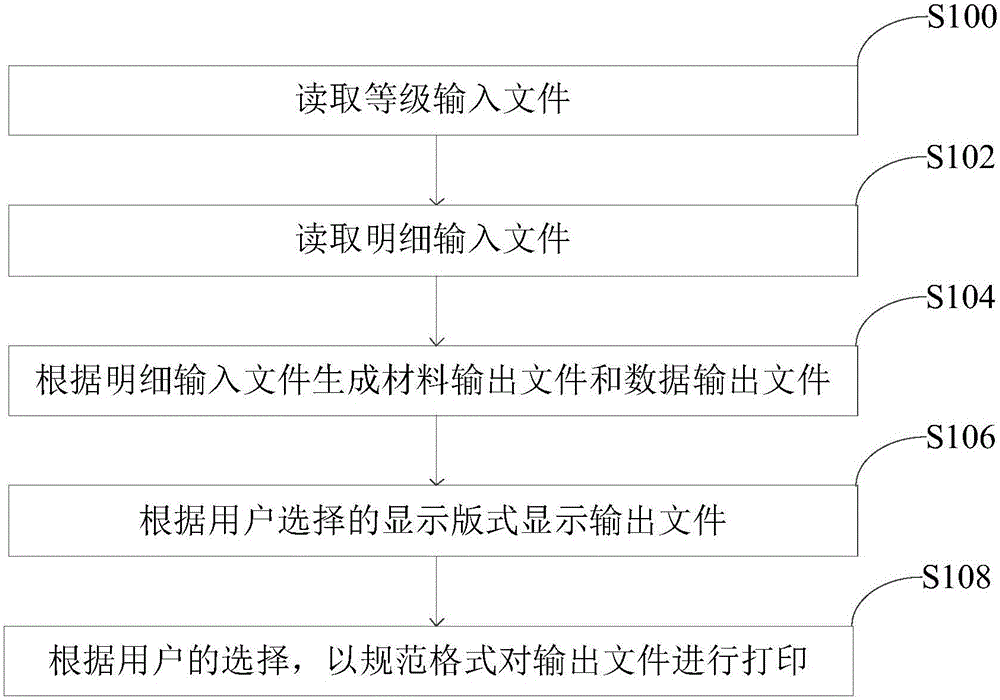

[0044] like figure 1 As shown, the embodiment of the present invention provides a pipe file management method, including the following steps:

[0045] S100. Read the grade input file

[0046] The grade input file contains raw data for pipe grades.

[0047] The preferred implementation of this step is: read the level input file and automatically identify or correct the identifiable errors in the level input file through fuzzy recognition, improve the correct rate of the output file, and at the same time facilitate the user to use and check.

[0048] It should be noted that identifiable errors include spaces, English letter case, quotation marks under Chinese and English input methods, "." and ".", etc. For identifiable errors, you can choose to only identify or only correct them, or both Identification and correction, if you choose to correct or mark while correcting, then the corrected original data will be entered into the database.

[0049] This embodiment can directly re...

Embodiment 2

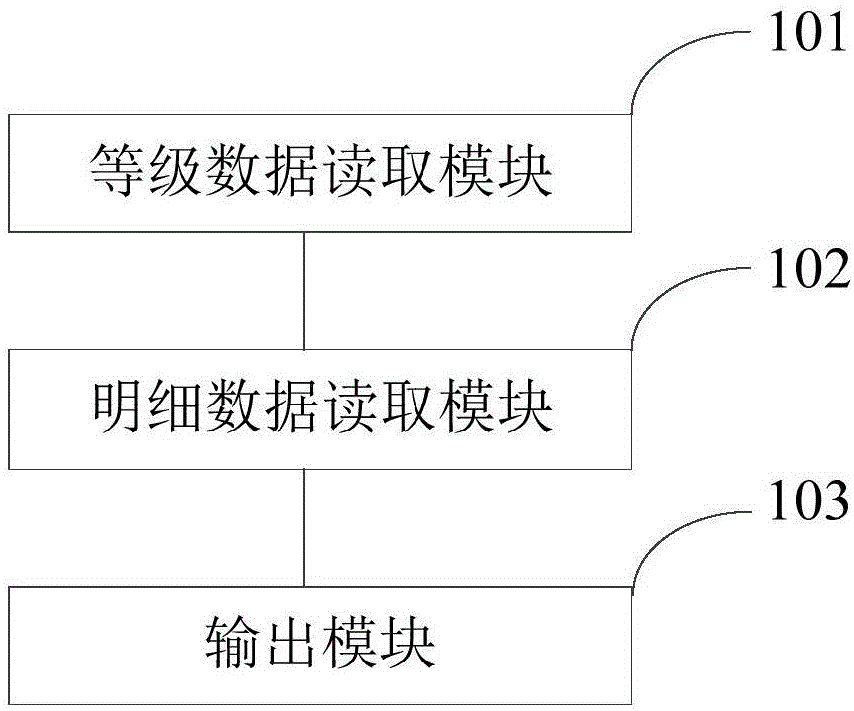

[0068] like image 3 As shown, the present embodiment provides a pipe file management system, including a grade data reading module 101, a detailed data reading module 102 and an output module 103; the grade data reading module 101 is used to read grade input files, grade input The file includes the raw data of the pipe grade; the detailed data reading module 102 is used to read the detailed input file, and the detailed input file includes the pipe grade and the pipe quantity; the output module 103 is used to generate the material output file and data output according to the detailed input file document.

[0069] In this embodiment, the grade input file is read by the grade data reading module 101, and the grade input file includes the original data of the pipe grade; the detailed input file is read by the detailed data reading module 102, and the pipe grade is associated with the grade input file; output Module 103 generates material output files and data output files accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com