Roll toilet paper extracting device

A technology of toilet paper and roll paper, which is applied to home appliances and other directions, and can solve the problem of roll toilet paper pollution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

[0017] The reference signs in the accompanying drawings of the specification include:

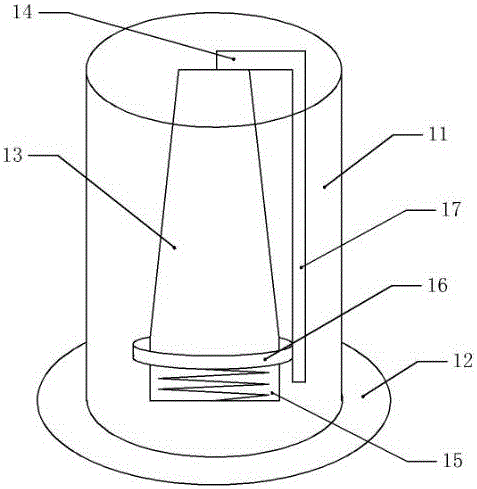

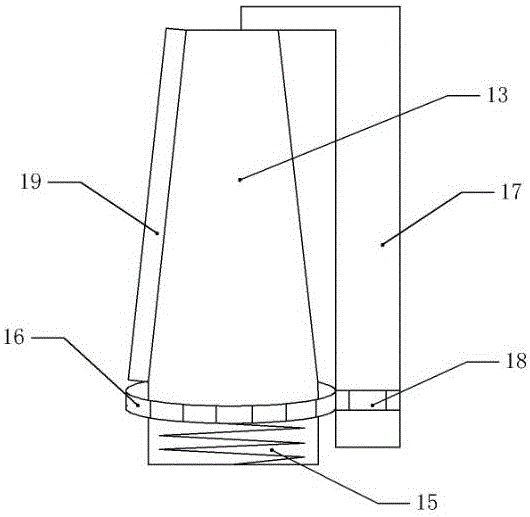

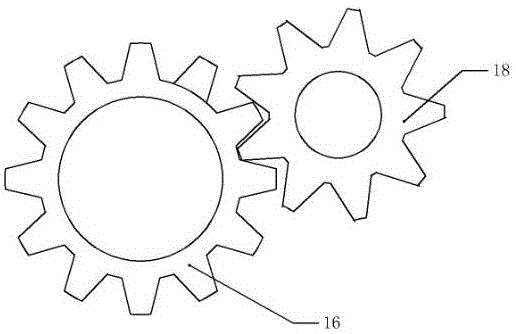

[0018] Paper roll 11, backing plate 12, paper roll core 13, pressure block 14, return spring 15, large gear 16, rotating shaft 17, pinion gear 18, paper outlet 19.

[0019] Such as figure 1 The roll toilet paper extraction device shown includes a roll paper 11 and a roll paper core 13, the roll paper core 13 is placed in the middle of the roll paper 11, and the roll paper core 13 is a hollow roll paper core 13 with a side wall of 1.5 cm. 13 is trapezoidal, and roll paper core 13 sidewalls are provided with four such as figure 2 As shown in the paper outlet 19, the lower end of the roll paper core 13 is covered with image 3 As shown in the large gear 16, a rubber layer is arranged between the paper core 13 and the large gear 16. The upper end of the paper core 13 is open, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com