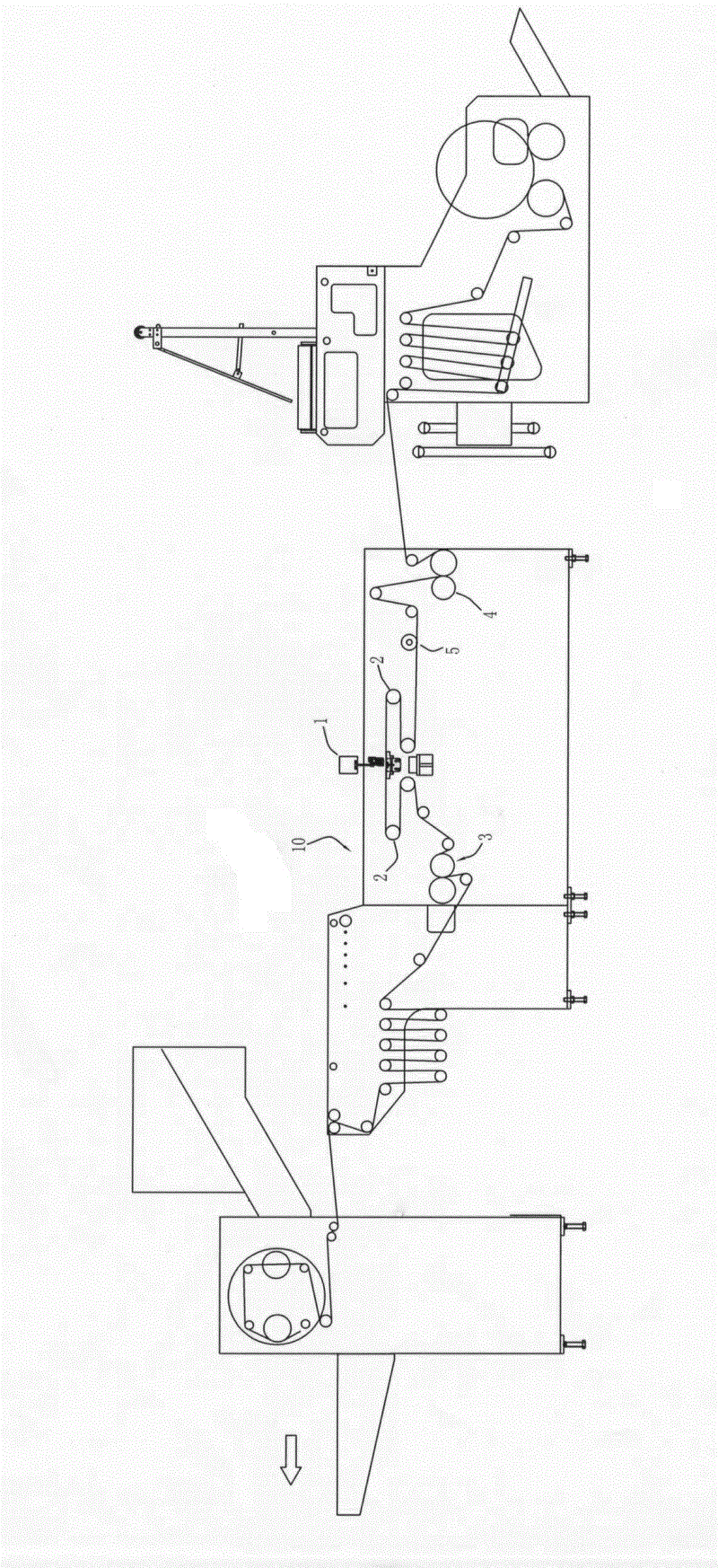

Point-cutting device for bag making machine

A bag-making machine and point-breaking technology, applied in container manufacturing machinery, packaging, transportation and packaging, etc., can solve the problems that the bag body is easily torn, affect the quality of the bag body, and increase the waste rate, so as to avoid being torn. , The effect of reducing scrap rate and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

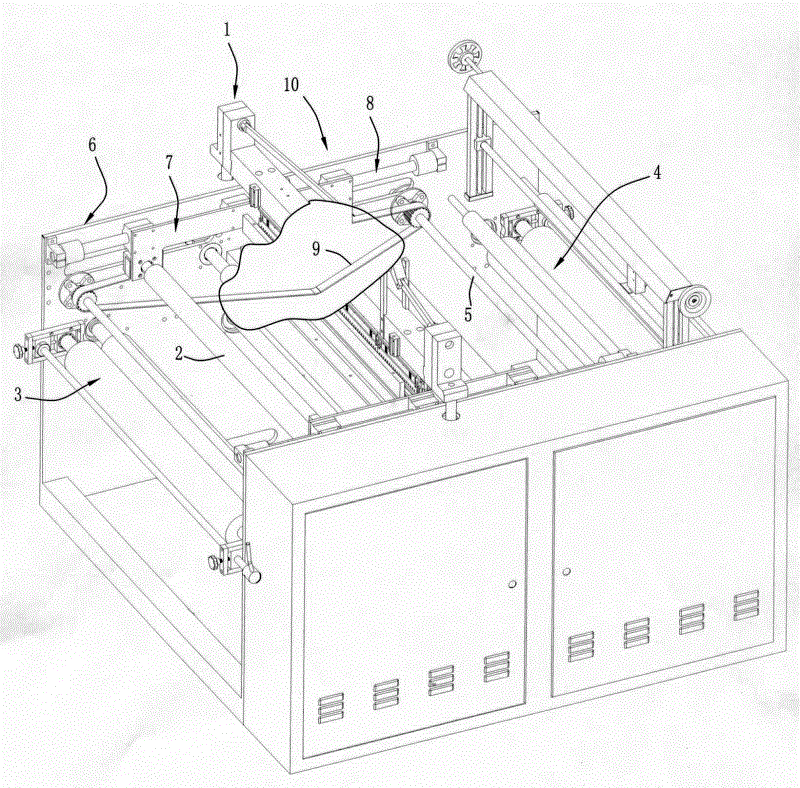

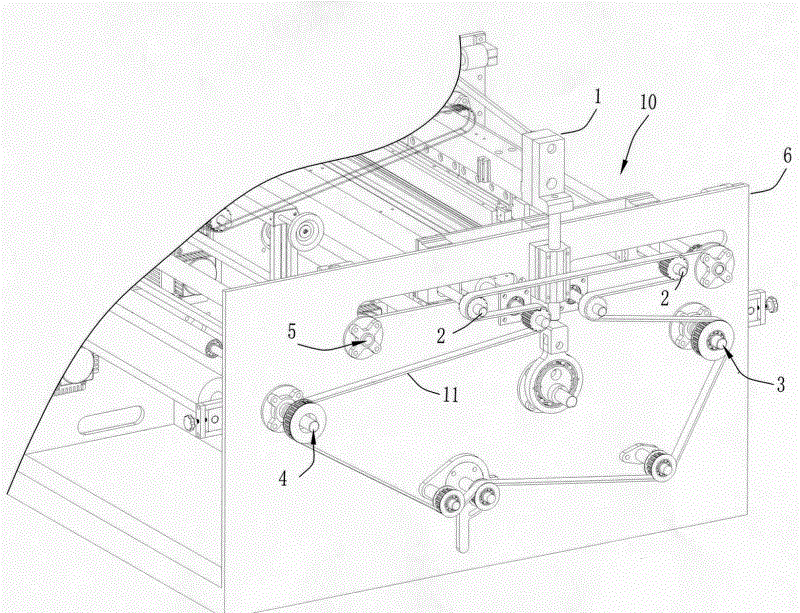

[0012] Referring to the accompanying drawings, the point breaking device of this kind of bag making machine includes a frame 6, a point breaking sealing knife set 1 and a bag conveying mechanism 10, and the point breaking sealing knife set 1 is arranged above the bag conveying mechanism 10 , the bag conveying mechanism 10 includes a transmission roller 2, a material feeding traction roller 4, a material discharge traction roller 3 and a conveying swing member, and the feeding traction roller 4, the material discharge traction roller 3 and the transmission roller 2 pass through a transmission belt 11 Transmission connection; the conveying swing part includes a swing bracket 7, the transmission roller 2 is installed on the swing bracket 7, the frame 6 is provided with a slide rail 8, and the swing bracket 7 passes through the transmission part along the slide rail 8 Move; the transmission part includes a transmission shaft 5, a transmission belt 9 and a motor, the transmission sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com