Fine micro-powder high pressure dispersing equipment

A high-pressure dispersion and equipment technology, applied in the direction of dissolution, mixers, chemical instruments and methods, etc., can solve the problems of long time consumption and achieve the effect of shortening the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

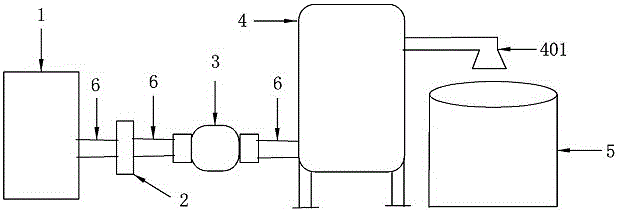

[0008] The following is attached figure 1 To describe the principles and features of the present invention, the examples cited are only used to explain the present invention, not to limit the scope of the present invention.

[0009] Such as figure 1 As shown, the fine powder high-pressure dispersion equipment is composed of a mixer 1, a glass tube flow meter 2, a high-pressure head pump 3, a pressure vessel 4, and a material tank 5. The high-pressure head pump 3 is connected to the mixing material through the conveying pipeline 6 The glass tube flowmeter 2 is installed on the feed pipe 6 connecting the high-pressure head pump 3 and the mixer 1, and the pressure vessel 4 is connected to the high-pressure head pump 3 through the feed pipe 6. The tank 5 is located below the discharge port 401 of the pressure vessel 4.

[0010] In the process of fine powder production and discharge of fine particles, the fine powder high-pressure dispersion equipment of the present invention is turne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com