A rotational molding platform

A rotomolding and platform technology, applied in coating and other directions, can solve the problems of heat uniformity rotomolding process time and process conditions, difficult to control, unfavorable product wall thickness uniformity, etc., to achieve the effect of precise control and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

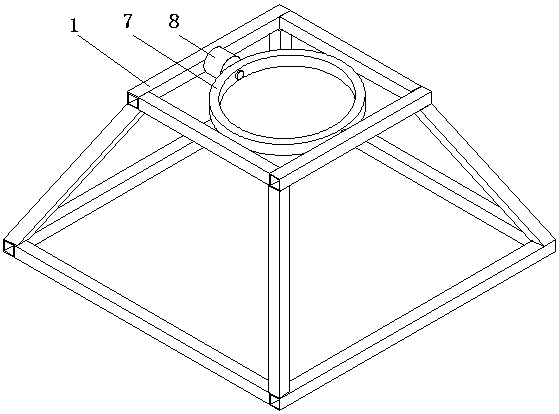

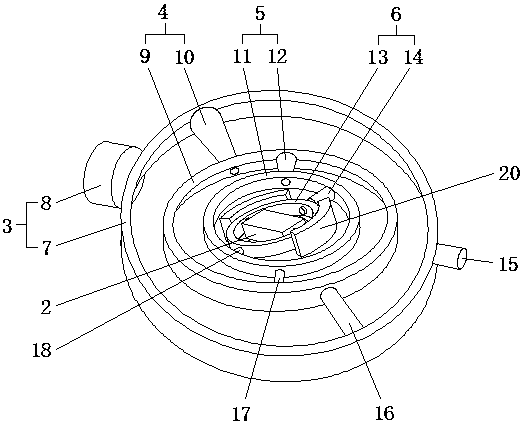

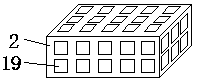

[0028] see Figure 1-Figure 3 , this embodiment includes a support frame 1, a console, a rotating system, a heating system, a cooling system and a mold 2.

[0029] The support frame 1 is a convex platform with an isosceles trapezoidal cross-section composed of twelve support rods, and its internal space is in a hollow state. The rotating system is fixed on the upper end surface of the trapezoidal convex platform, and the rotating system can obtain enough space when rotating. to rotate.

[0030] There is a control system on the console, which is directly connected with the rotation system, heating system and cooling system respectively, and the operator only needs to directly interact with the control system to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com