Organic glass adhesion sealing injection device

A plexiglass and material injection technology, which is applied to flat products, household utensils, and other household utensils, etc., to reduce disassembly work, ensure smoothness, and ensure the effect of glue feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

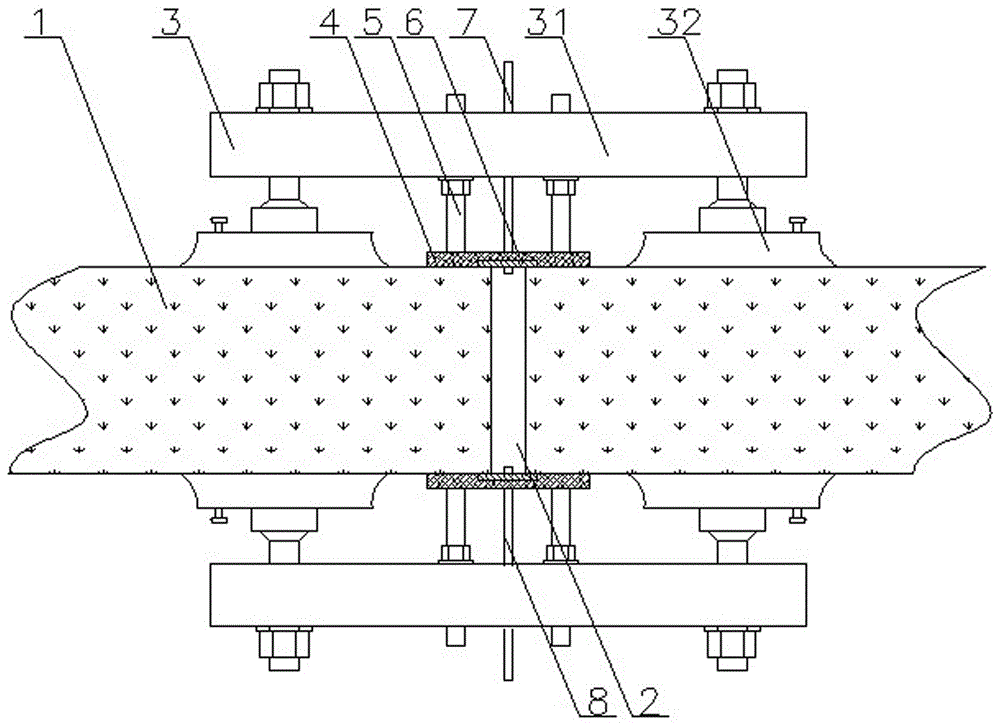

[0011] In the production process of plexiglass, due to the limitation of the mold, the oversized plexiglass needs to be spliced, and the plexiglass is glued to each other. Align the two pieces of plexiglass 1 and leave the seam 2 to be connected.

[0012] In order to ensure the connection quality, this technical solution provides a plexiglass bonded sealing injection device, including a pair of suction cup tooling 3, a pair of aluminum pressure plates 4 and a plurality of pressure rods 5, the suction cup device 3 includes a support plate 31, The four corners of the support plate 31 are respectively equipped with suction cups 32, and the suction cups 32 are sucked on the surface of the plexiglass to be connected and distributed on both sides of the joint 2 to be connected; the pair of aluminum pressing plates 4 are covered from both sides of the plexiglass 1 Connect the seam 2, two aluminum pressure plates 4 and the two faces of the plexiglass to be connected to form a glue-fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com