Toothed rail-trapped rail sightseeing train

A sightseeing car and rail clamping technology, which is applied in the field of sightseeing cars, can solve problems such as bad scenic spots, complete line paralysis, singleness, etc., and achieve the effects of avoiding exhaust emissions and noise pollution, wide application range, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

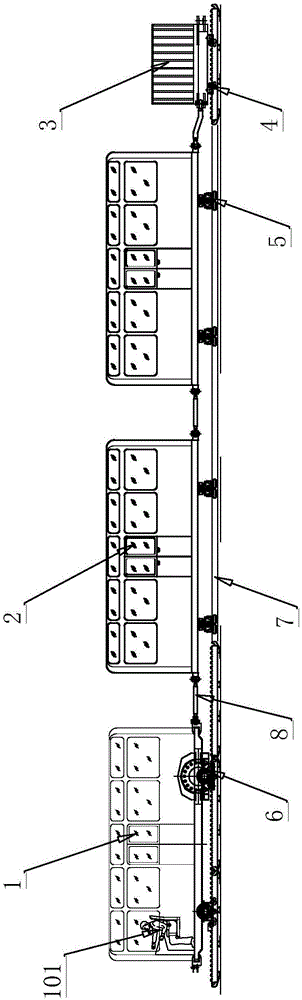

[0040] Such as Figure 1-8 Shown, the present invention a kind of cog rail clip sightseeing car, comprises track 7 and sightseeing car base body, and sightseeing car base body slides on track 7, and track 7 comprises a plurality of turnout tracks that are connected together, and switch track is provided with Turnout slideway, the two ends of the turnout track are equipped with a track-changing cylinder, and the turnout track slides on the turnout slideway under the drive of the track-changing cylinder to realize track change. Scenic lines;

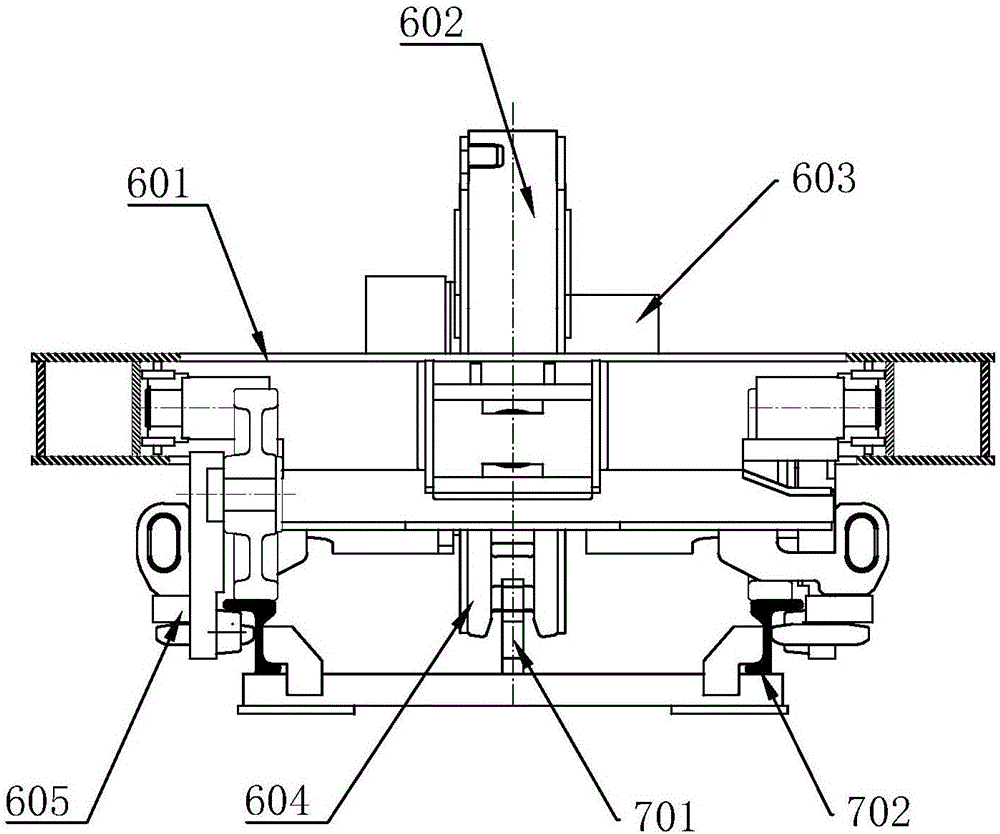

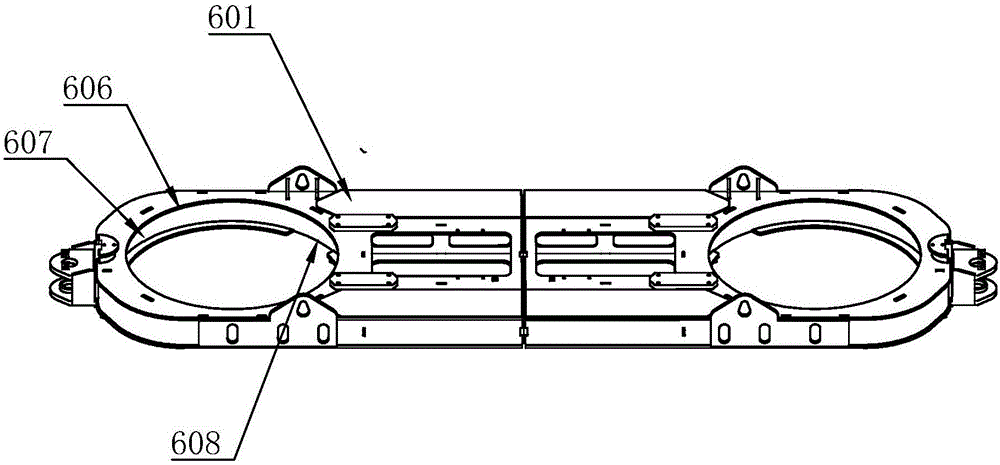

[0041] The turnout track includes two disjoint straight rails and curved rails, the straight rail and the curved rail respectively include a profile, a rack 701 located in the middle of the profile and special-shaped rails 702 located at both ends of the profile;

[0042] The base body of the sightseeing car includes a power compartment 1, a passenger compartment 2 and a brake car 3, and a tie rod 8 is arranged between the power compartme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com