Floating carrier capable of achieving product accurate positioning

A precise positioning and carrier technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of low transmission accuracy and difficulty in meeting product assembly accuracy, and achieve the effect of ensuring processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

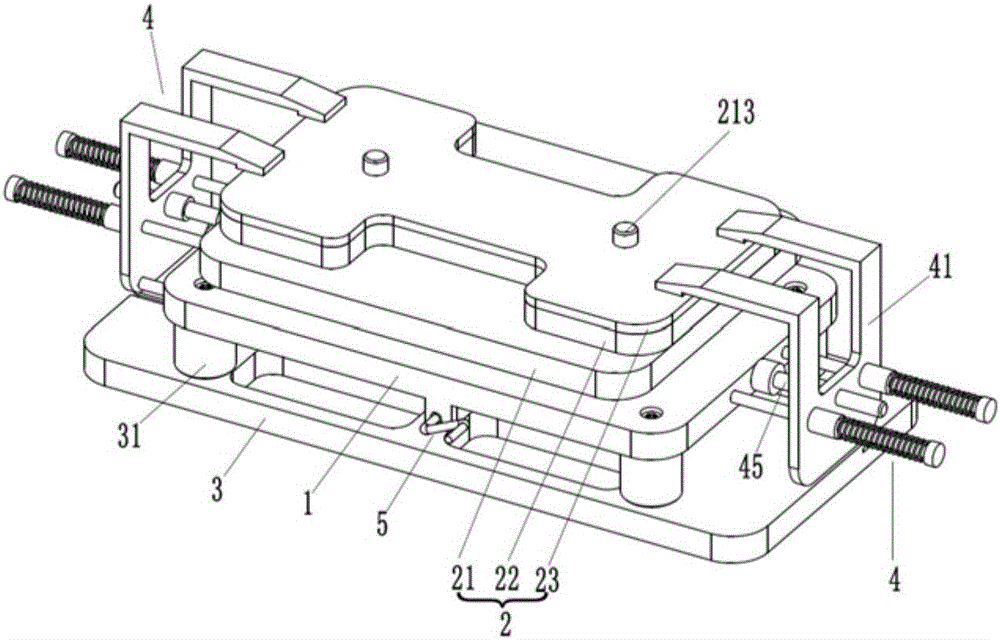

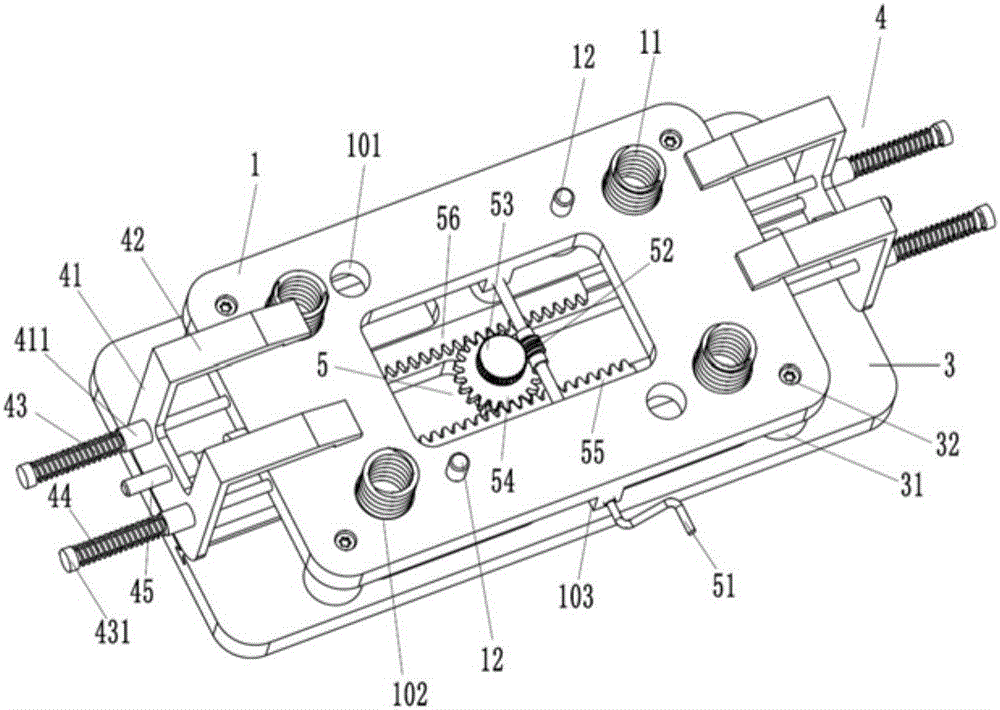

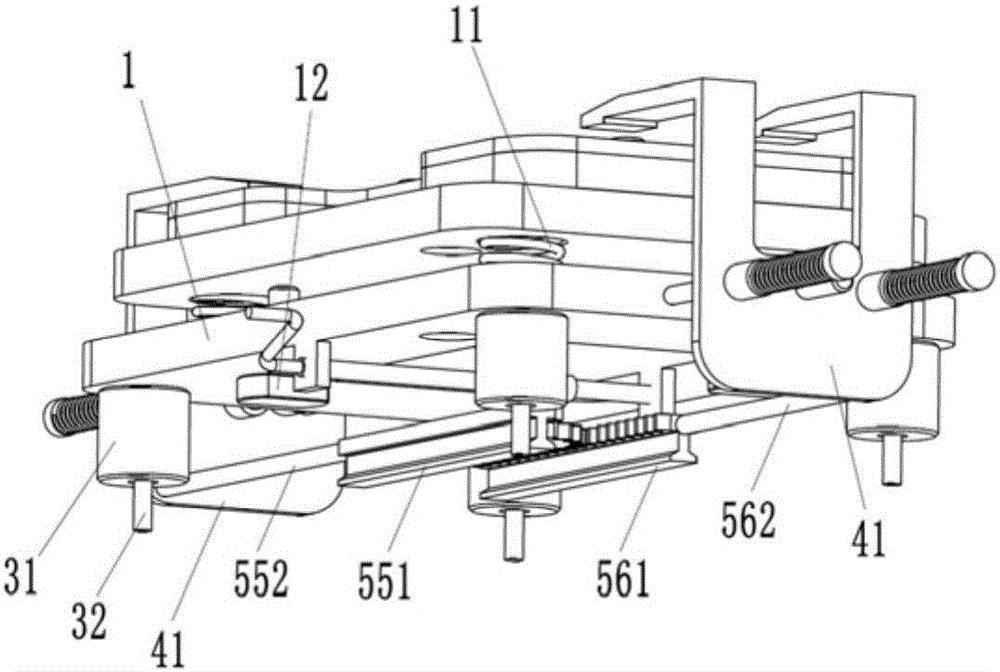

[0024] Examples, see e.g. Figure 1 to Figure 5 As shown, a floating carrier capable of realizing precise positioning of products includes a floating plate 1 on which a jig base 2 is floatingly connected. The floating plate 1 is fixed on a fixed plate 3. The left and right sides of the floating plate 1 are respectively The pressure claw assembly 4 is installed, the pressure claw assembly driving device 5 is installed on the fixed plate 3, a guide through hole 101 is formed on the floating plate 1, and a positioning hole 211 is opened on the clamp base 2, and the guide through hole 101 and the positioning hole 211 are up and down align.

[0025] Furthermore, the clamp base 2 includes a lifting plate 21, two positioning holes 211 and four spring socket holes 212 are formed on the lower surface of the lifting plate 21, and the spring socket holes 212 are located at the bottom of the lifting plate 21. Four corners, two positioning pins 213 are fixed on the upper bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com