Production process of early-strength alkali-free accelerating agent and product obtained with production process

A production process and technology of accelerators, which are applied in the field of concrete admixture preparation technology, can solve the problems of large damage to construction workers, high prices of low-alkali accelerators, and large loss of concrete strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

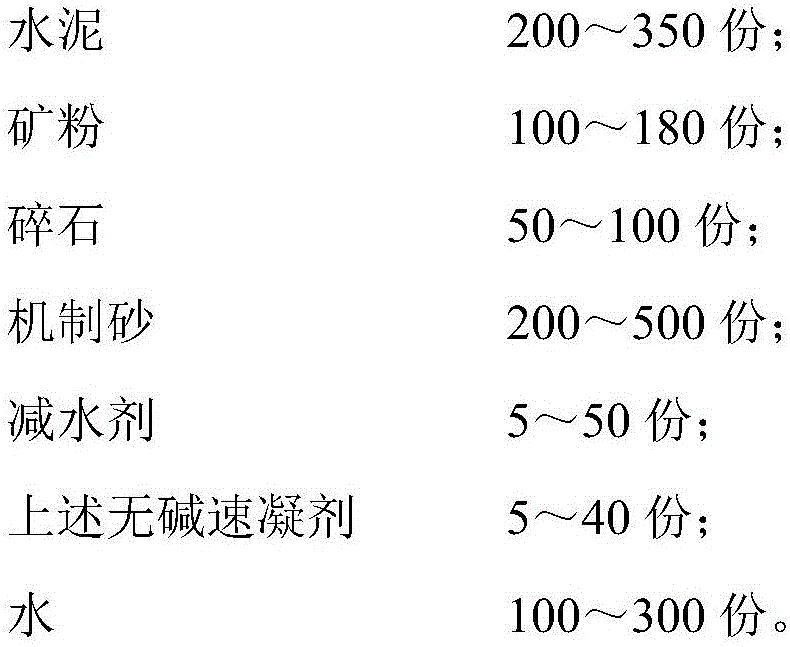

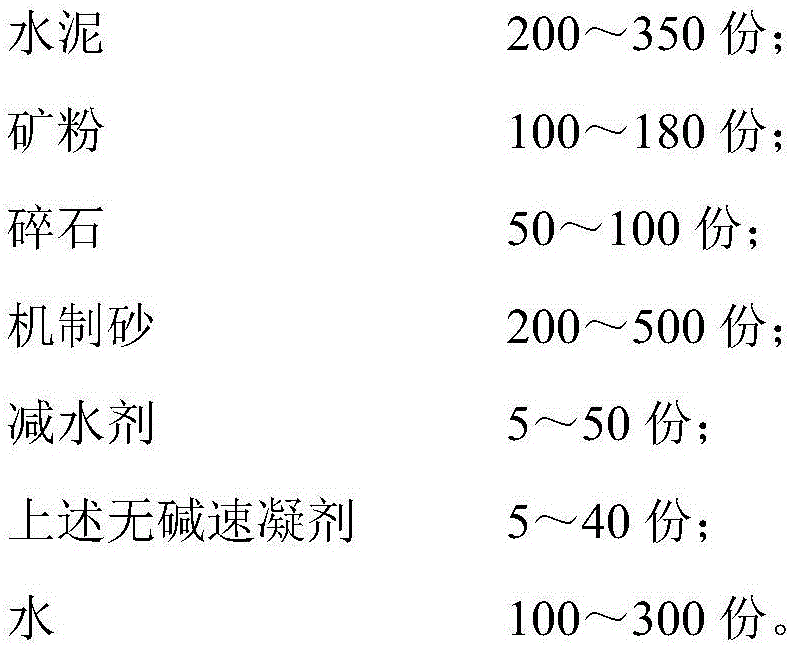

[0074] A fifth aspect of the present invention provides a method for preparing high-strength concrete, at least including the following steps:

[0075] Weigh each component according to the ratio, add cement, mineral powder water reducer, alkali-free quick-setting agent and water into the mixer and stir evenly to obtain a mixed solution, finally add crushed stone and machine-made sand, and stir evenly to obtain high-strength concrete .

Embodiment 1

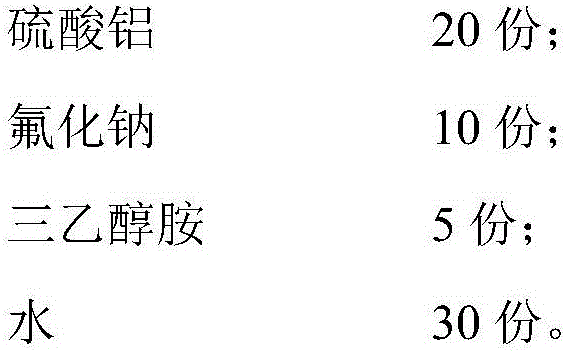

[0079] Embodiment 1 of the present invention provides a kind of early-strength type non-alkali quick-setting agent production process, wherein, early-strength type non-alkali quick-setting agent, by weight, comprises the following components:

[0080]

[0081] The production process of the early-strength type alkali-free accelerator at least includes the following steps:

[0082] (1) Take the following components respectively according to the proportioning ratio: aluminum sulfate, sodium fluoride, ethanolamine, water;

[0083] (2) First add water to the reaction kettle, heat to 40°C, add aluminum sulfate and stir until it is completely dissolved, then add sodium fluoride, after the sodium fluoride is completely dissolved, then add ethanolamine, and after the ethanolamine is completely dissolved, the early Strong alkali-free accelerator.

Embodiment 2

[0085] Embodiment 2 of the present invention provides a kind of early-strength type non-alkali quick-setting agent production process, wherein, early-strength type non-alkali quick-setting agent, by weight, comprises the following components:

[0086]

[0087] The production process of the early-strength type alkali-free accelerator at least includes the following steps:

[0088] (1) Take the following components respectively according to the proportioning ratio: aluminum sulfate, sodium fluoride, ethanolamine, water;

[0089] (2) First add water to the reaction kettle, heat it to 60°C, add aluminum sulfate and stir until it is completely dissolved, then add sodium fluoride, after the sodium fluoride is completely dissolved, then add ethanolamine, and after the ethanolamine is completely dissolved, the early Strong alkali-free accelerator.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap