Passion fruit fermented product, preparation method and tobacco product containing fermented product

A technology of passion fruit and fermented product, applied in the field of tobacco, can solve problems such as undiscovered application of passion fruit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 100

[0080] The preparation of embodiment 1 passion fruit fermented product 1

[0081] The method for preparing the passion fruit juice comprises the following steps: peeling the passion fruit and directly pressing out the juice to obtain the passion fruit juice.

[0082] Stir 100.0g of passion fruit juice, 3.0g of powdered rice koji (purchased from Shandong Liangshan Xufang Daqu Co., Ltd.) and 600g of water, and ferment in open mode at 15°C for 15 days, and filter the fermented substance with rapid quantitative filter paper , collect the filtrate. The filtrate was concentrated to 30 mL by a rotary evaporator, the rotation speed of the rotary evaporator was 110 rpm, the concentration vacuum was 210 mbar, and the concentration temperature was 70° C. The concentrated solution was centrifuged at a speed of 8000 rpm for 10 minutes, and the collected supernatant was Passion Fruit Ferment 1.

Embodiment 2 100

[0083] The preparation of embodiment 2 passion fruit fermented product 2

[0084] The preparation method of passion fruit juice is with reference to embodiment 1.

[0085] Stir 100.0g of passion fruit juice, 5.0g of powdered rice koji (purchased from Xufang Daqu Co., Ltd., Liangshan, Shandong) and 800g of water, and ferment in open mode at 12°C for 17 days, and filter the fermented substance with rapid quantitative filter paper , collect the filtrate. The filtrate was concentrated to 35 mL by a rotary evaporator, the rotating speed of the rotary evaporator was 120 rpm, the concentration vacuum was 220 mbar, and the concentration temperature was 80° C. The concentrated solution was centrifuged at a speed of 8000 rpm for 10 minutes, and the supernatant was collected as Passion Fruit Ferment 2.

Embodiment 3 100

[0086] The component analysis of embodiment 3 passion fruit fermented product

[0087] Passion fruit fermented product 1 pretreatment that embodiment 1 obtains, and analyze its composition and content, concrete method is as follows:

[0088] Passion fruit fermented product 1 was extracted with dichloromethane, the volume ratio of dichloromethane to passion fruit fermented product 1 was 1:1, extracted 3 times in total, and the extracts were combined. Take 70mL extract, concentrate under reduced pressure (G3 rotary evaporator, Heidolph Company), concentration temperature is 39°C, vacuum degree is 750mbar, rotation speed is 110rpm, and concentrated to 2.0mL. Add 10.0 μL of internal standard phenylethyl acetate (12.553 mg / mL), shake well, filter the membrane, and transfer to a chromatographic vial as the sample to be tested.

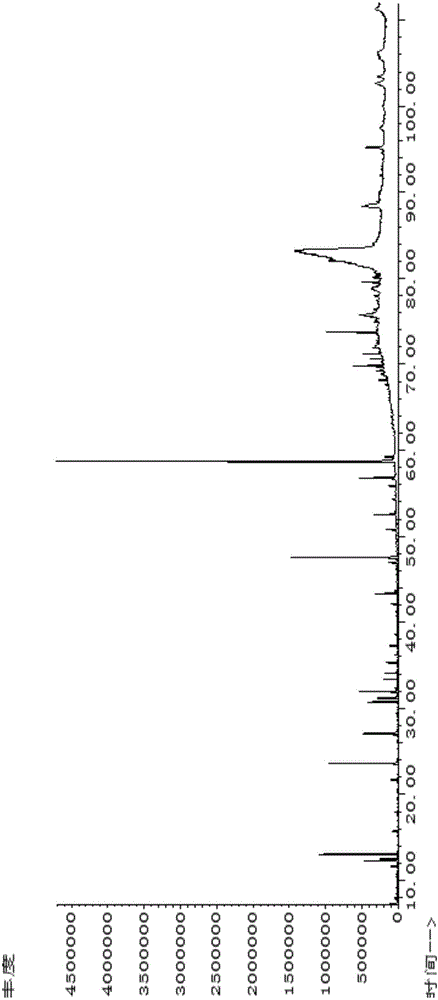

[0089] The samples to be tested were analyzed by gas chromatography-mass spectrometry, and the test results were as follows: figure 1 shown.

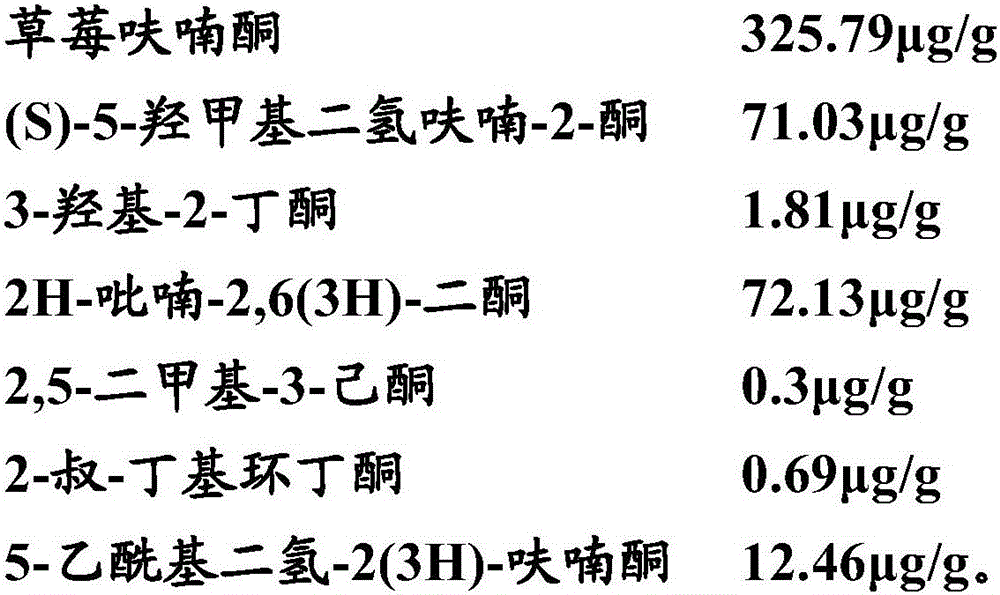

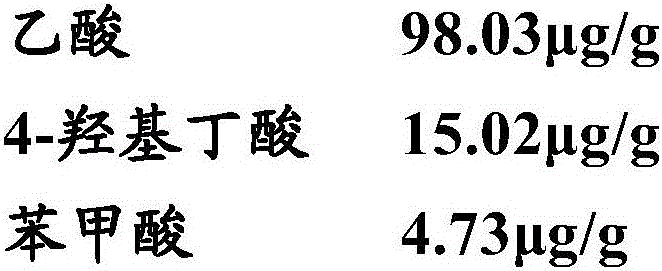

[0090] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com