Segmented hole-sweeping and retreating controlled grouting equipment for avoiding grouting walls

A retreating and controllable technology, which is applied in mining equipment, shaft equipment, shaft lining, etc., can solve the problems of affecting the grouting pressure, multiple construction procedures of the grouting wall, and easy blockage of the grouting pipe, so as to ensure the grouting Pressure, the effect of preventing the rock surface from overflowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

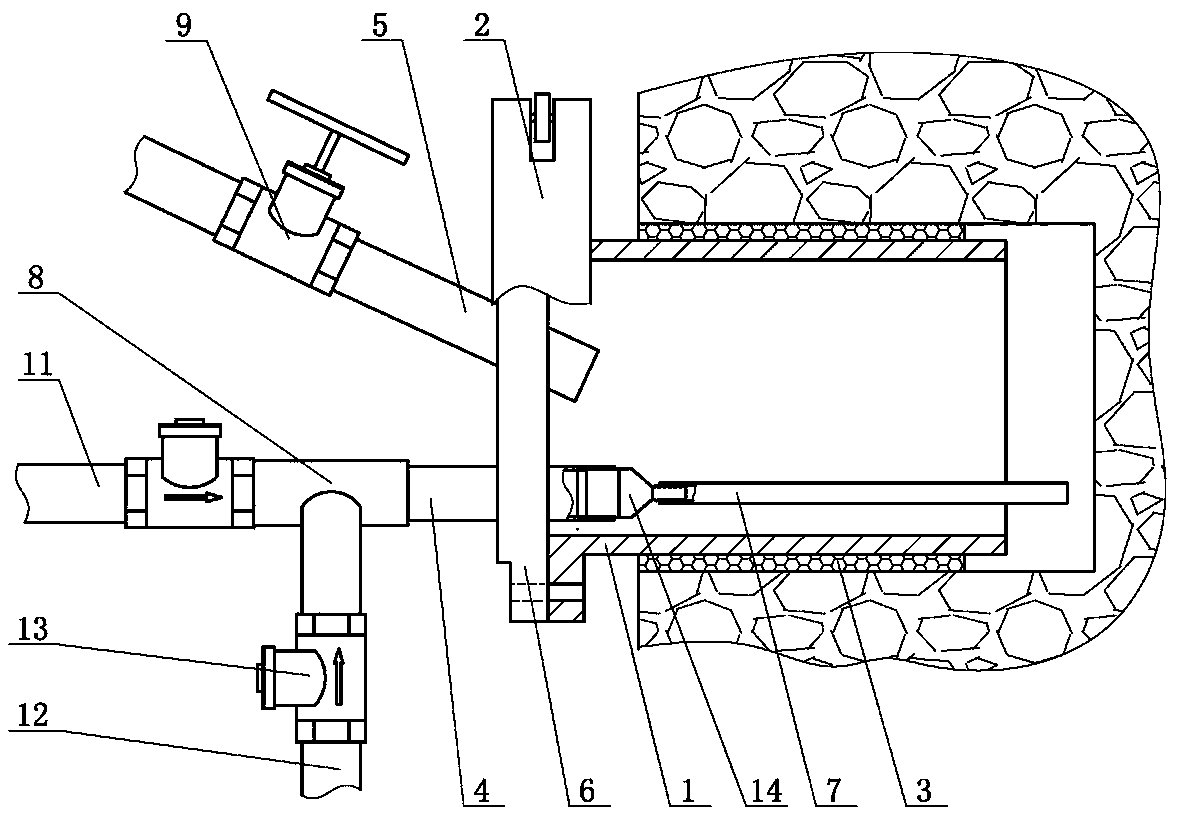

[0007] The grout-free wall segmental sweeping and retreating control grouting equipment of the present invention includes an orifice pipe 1, one end of the orifice pipe 1 is connected to a disc 6 through a quick flange joint 2, and the disc 6 is far away from the orifice pipe 1. The slurry inlet pipe 4 and the slurry outlet pipe 5 are installed on one side. The slurry inlet pipe 4 communicates with the cement slurry pipeline 11 and the control fluid pipeline 12 respectively through the slurry mixer 8. The slurry mixer 8 can adjust the mixing ratio of the cement slurry and the control fluid. A valve 9 is installed on the outlet pipe 5, the inlet pipe 4 and the outlet pipe 5 are connected to the orifice pipe 1, the orifice pipe 1 is provided with a grouting pipe 7, and one end of the grouting pipe 7 is connected to the grouting pipe 4, The length of the grouting pipe 7 is greater than the length of the orifice pipe 1 . When in use, use a drilling rig to drill a hole 2.5m-3.0m de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com