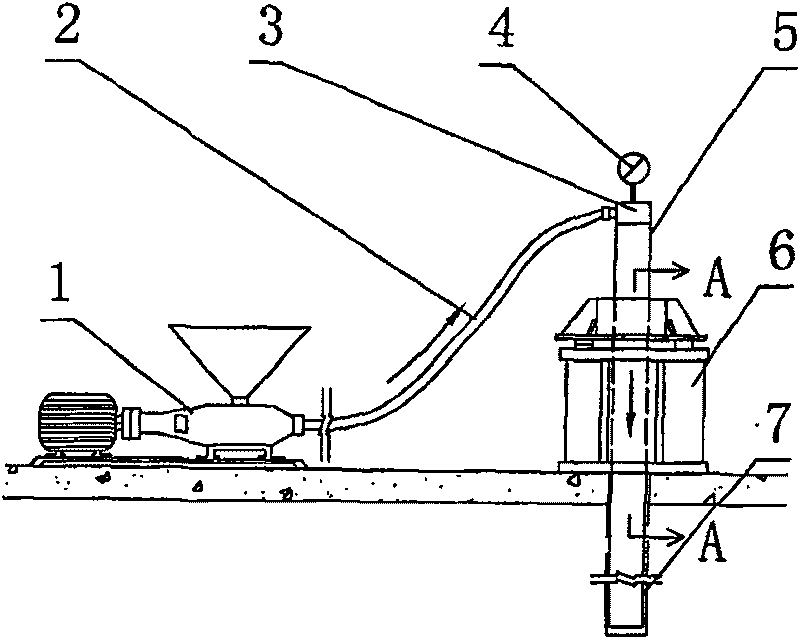

Sleeve grouting method and grouting device thereof

A casing and wall protection casing technology, which is applied in construction, infrastructure engineering, etc., can solve the problems of low work efficiency, large gap between drill pipe and hole wall, small grouting pipe, etc., achieve convenient disassembly and use, and improve equipment utilization efficiency and ensure the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

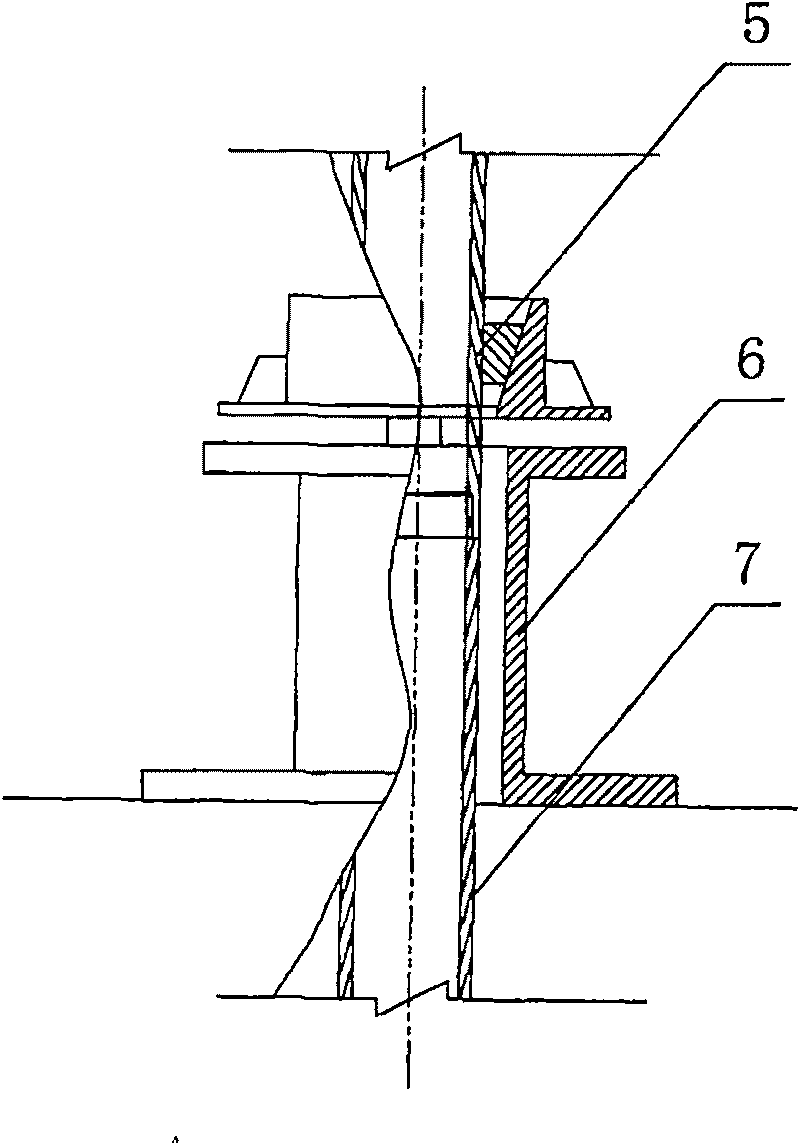

Method used

Image

Examples

Embodiment

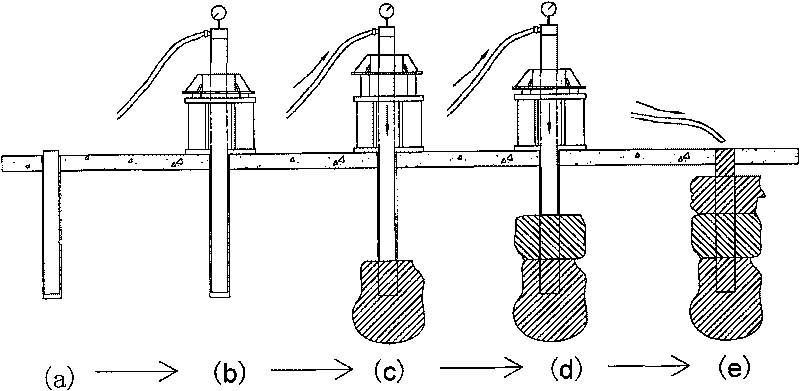

[0047] Such as image 3 Shown, casing grouting method of the present invention is to implement by following specific construction steps:

[0048] 1. Drilling of follow pipe and laying of wall casing. Such as image 3 As shown in (a), before grouting, drill holes to the designed hole depth (30m) by using the pipe drilling method. The drilling machine is a bolter drill equipped with an impactor and a percussion drill bit with eccentric or concentric pipe drilling. Drilling, the bore hole diameter is Φ146 (mm), when drilling, the drill bit drives the wall protection casing 7 into the hole, after the final hole, the drill bit and the drill pipe are taken out, and the wall protection casing 7 is left in the hole; the wall protection casing 7 is formed by The multi-section pipes are connected by threads, and the drill pipe is also made of multi-section pipes through threaded connections. The length of each section matches the length of the sub-rods. Afterwards, connect a joint su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com