Wall-for-grouting-free segmentation drill-hole-cleaning retrogressive controllability grouting method

A retreating, grout-stopping wall technology, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of many construction procedures of grout-stopping wall, affecting grouting pressure, and complicated construction, so as to prevent rock surface overflow. grouting, ensuring the effect of grouting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

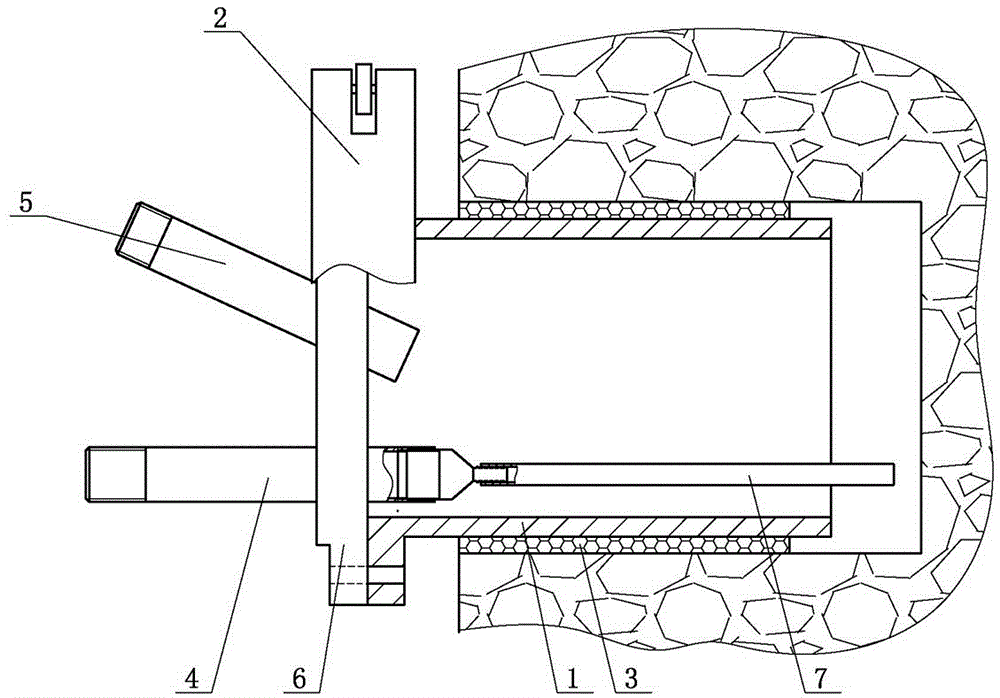

[0019] The stepwise sweeping and retreating controlled grouting method of the grout-free wall of the present invention comprises the following steps:

[0020] ① Drill a shallow hole with a depth of 2.5m-3.0m on the original surrounding rock with a drilling rig, and withdraw the drill pipe;

[0021] ②Take the orifice tube 1 with the flange quick connector 2 at the nozzle, wind the hemp silk from the outer wall of the orifice tube 1 to the other end of the orifice tube 1 at a distance of 230cm from the flange quick connector, and wrap the outer wall of the orifice tube The length of the hemp wrapping layer 3 formed is 80cm-120cm, and is laid on the surface of the hemp silk wrapping layer 3 using cement slurry;

[0022] ③Take the disk 6 matched with the flange quick connector 2 on the orifice pipe 1 in step ②, install the pulp inlet pipe 4 and the pulp outlet pipe 5 on one side of the disk 6, and the pulp inlet pipe 4 and the pulp outlet pipe 5 are all connected with each other. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com