Three-piece far infrared electric whole set focusing type uncooled lens

A far-infrared, three-chip technology, applied in installation, optics, instruments, etc., can solve the problems of optical system focal length change, image quality degradation, and image plane drift, etc., to achieve improved optical imaging performance, high pass rate, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above-mentioned features and advantages of the present invention more obvious and easy to understand, the following specific embodiments are given and the accompanying drawings are described in detail as follows, but the present invention is not limited thereto.

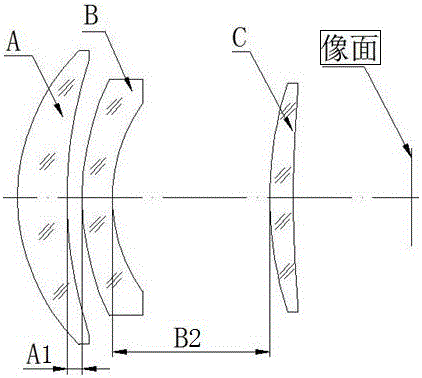

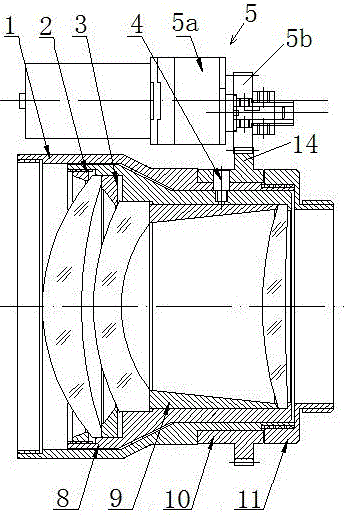

[0018] refer to Figure 1 to Figure 4

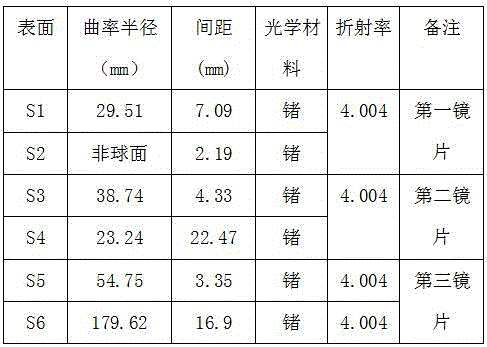

[0019] A three-piece far-infrared motorized group focusing type uncooled lens, comprising a main lens barrel 8, in the main lens barrel, a first lens A with positive focal power is sequentially arranged along the incident direction of light from front to back. The second lens B with negative refractive power and the third lens C with positive refractive power, the air space A1 between the first lens and the second lens is 2.19mm; the air space B1 between the second lens and the third lens is 22.43mm, and the first lens, the second lens and the third lens are respectively crescent lenses. The main lens barrel is covered with a sleeve 1, the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com