Working procedure management and control software for production processes of products

A production process and production management technology, applied in data processing applications, instruments, office automation, etc., can solve problems such as in place management, high market competition pressure, and reduced department execution, so as to improve efficiency, production and processing efficiency, and management process Clear and clear, the effect of improving production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

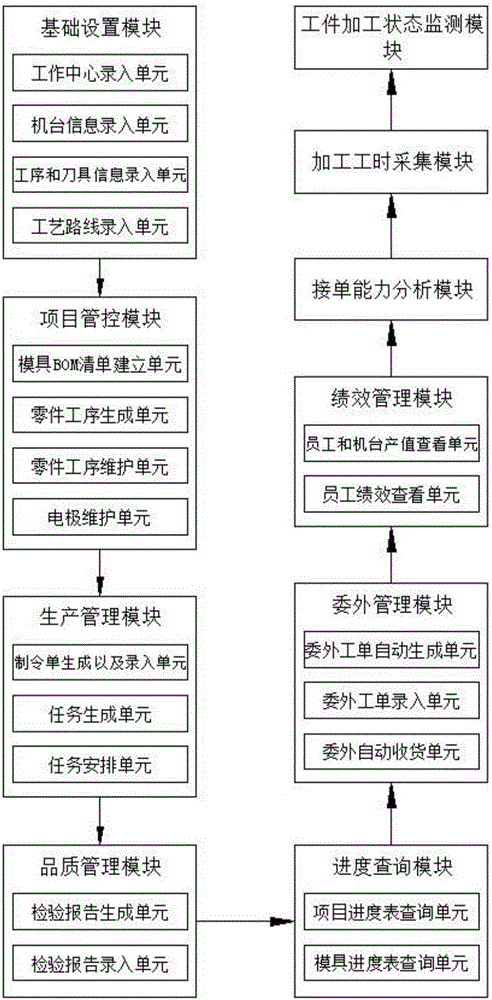

[0021] refer to figure 1 , a process control software for product production process, including basic setting module for basic setting, project control module for production project management and control, production management module for production process management, production quality improvement The quality management module, the progress query module for querying the progress of the production process, the subcontract management module for subcontract work order management, the performance management module for employee and machine management, and the capacity analysis module for work centers The order-receiving ability analysis module, the processing time collection module used to collect the actual processing time of the operator, the workpiece processing status monitoring module used to monitor the workpiece processing status, and the project management and control module are respectively connected with the basic setting module and the production management module. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com