A method for replacing the ei-type laminated silicon steel core transformer with a ring-type power transformer

A technology of power transformers and silicon steel cores, which is applied in the manufacture of inductors/transformers/magnets, transformer/inductor cores, transformer/inductor components, etc., can solve problems such as high cost, potential safety hazards, waste of resources, etc., and achieve Reduce costs, reduce manufacturing costs, and contribute to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

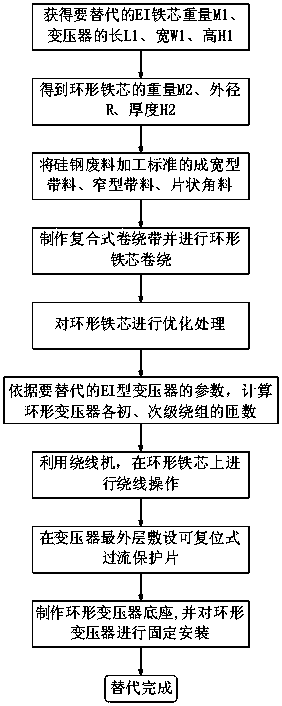

[0063] Referring to the accompanying drawings, the method for replacing the EI-type laminated silicon-steel core transformer by the toroidal power transformer of the present invention includes the following 10 steps, which will be analyzed in detail below.

[0064] Step 1), take the EI-type laminated silicon-steel core transformer to be replaced, obtain its core weight M1, and measure the length L1, width W1, and height H1 of the transformer.

[0065] Step 2), obtain the toroidal core parameters of the toroidal power transformer, the weight of the toroidal core M2= M1*(70±5)%, the outer diameter of the toroidal core R≤L1 and R≤L1, the thickness of the toroidal core H2≤H1 . Under the condition of equal power, the ring-type iron core replaces the EI-type iron core. Since the weight is reduced by 30%, the specific gravity of the two types of iron cores is the same, so the volume is smaller than the EI-type iron core. The diameter of the aluminum-clad enameled wire replacing the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com