Twin-cone pushing type middle quick energy-saving conducting contact

A conductive joint, extruded technology, applied in the direction of conductive connection, electrical component connection, circuit, etc., can solve the problems of difficult to disassemble the wire, easy to break, and the middle conductive joint is not suitable for use, so as to achieve safe use, good locking and The effect of conductive contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

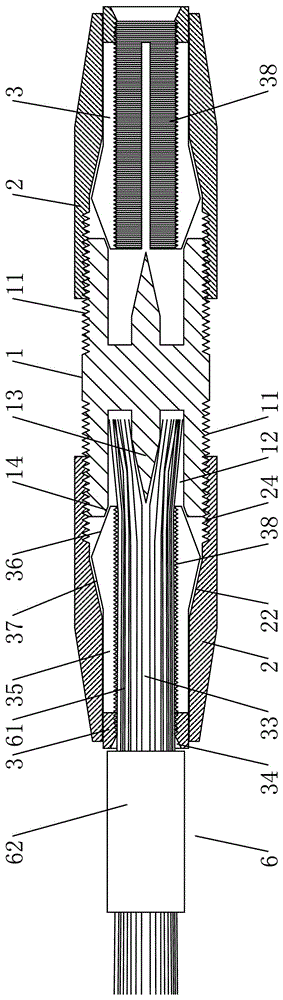

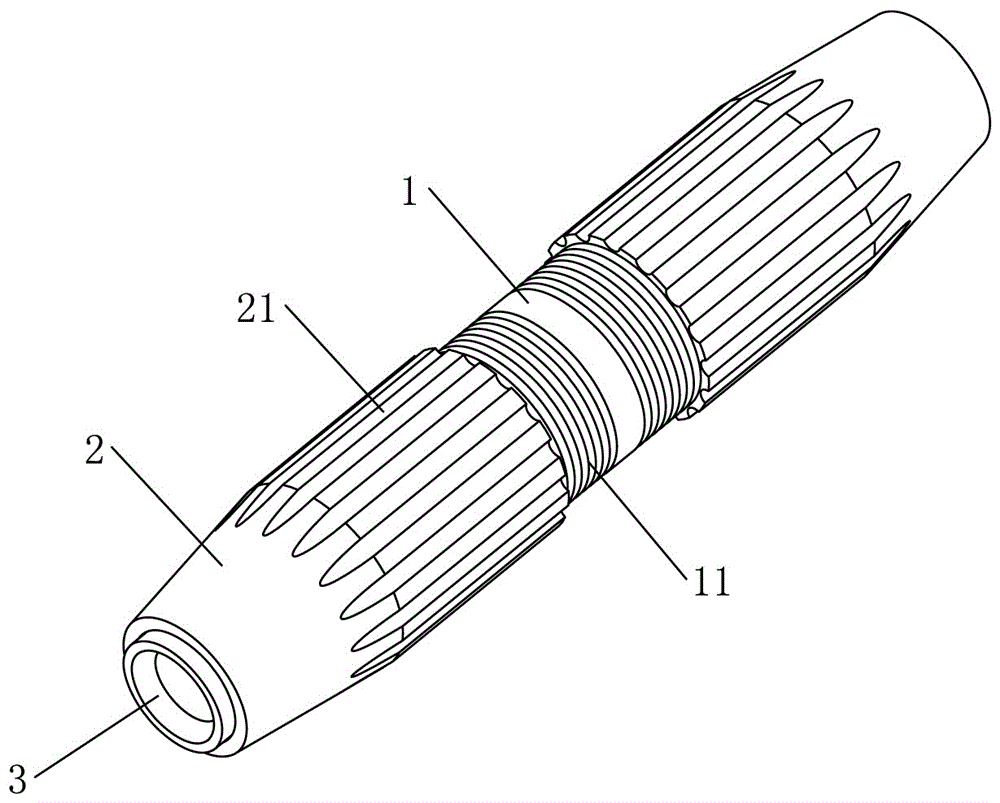

[0022] see figure 1 and figure 2 As shown, a double-cone extruded intermediate fast energy-saving conductive joint includes an intermediate conductive head 1, and the intermediate conductive head 1 is provided with two externally threaded ends 11, and the externally threaded ends 11 are provided with a conductive wire locking device. The conductive wire locking device comprises an outer lock nut 2 and an inner threading tight wire sleeve 3, the outer lock nut 2 is provided with a sleeve hole passing through its two ends, one end of the sleeve hole is provided with an internal thread 24, and the internal thread 24 and the external thread The end 11 is threaded; the inner threading tighter sleeve 3 is provided with a threading hole 33 passing through its two ends, and the surface of the threading hole 33 is axially provided with an elastic slot 35, and the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com