An insulation crossing machine

A wire machine and wire technology, applied in the field of electric power construction auxiliary equipment, can solve problems such as damage to new and old wires, achieve the effects of reducing construction links, improving the range of operability, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

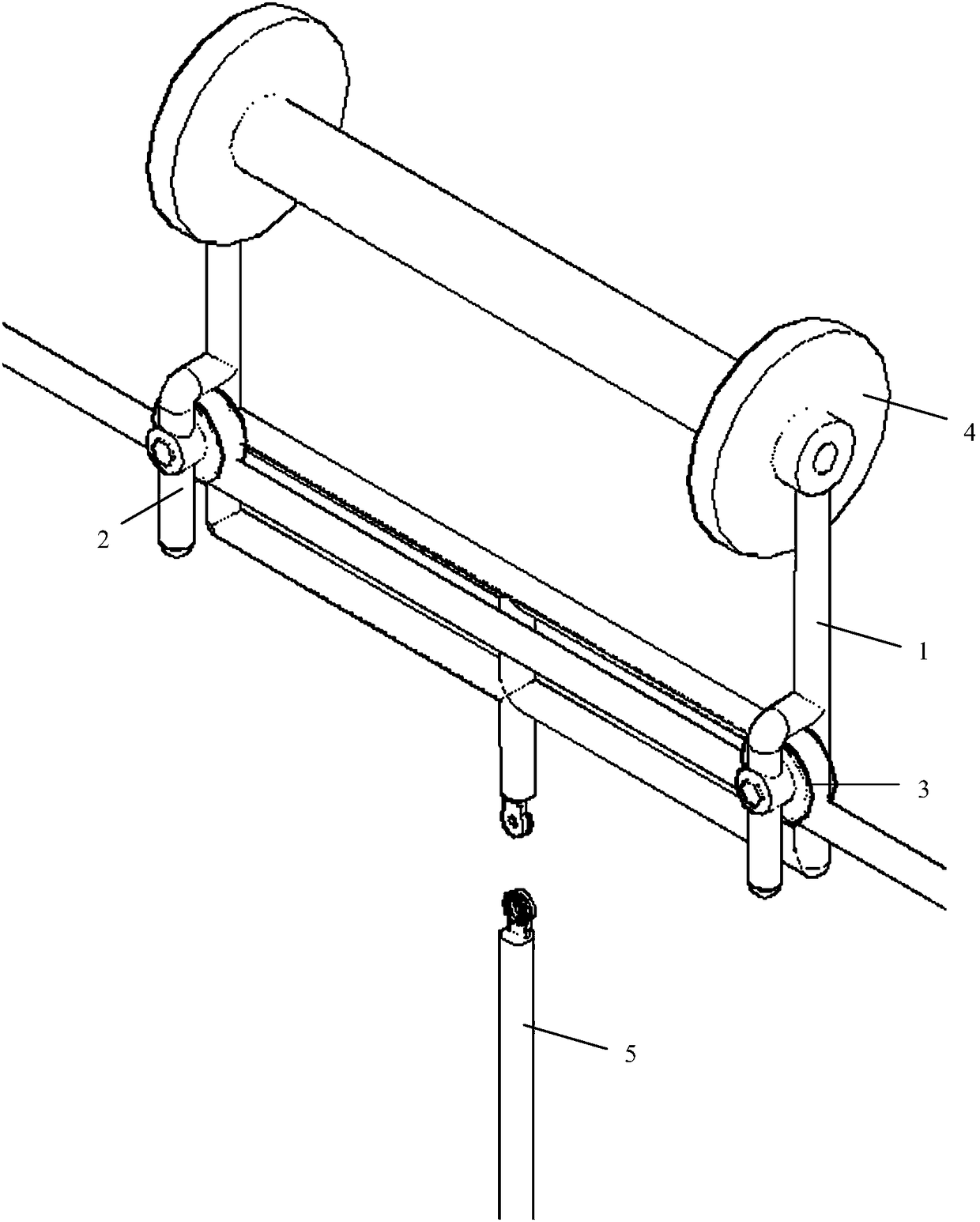

[0022] refer to figure 1 , an insulation spanning wire passing machine, comprising a frame-shaped support 1, and "7"-shaped rods 2 are fixedly connected to the vertical poles on both sides of the frame-shaped support 1 to form a fixed clip with an opening downward, and wiring is respectively arranged in the fixed clip The pulley 3 is used to be erected on the wire being spanned, and to walk on the wire being spanned. The upper cross bar of the frame support 1 is rotatably connected to the upper roller 4 for supporting the construction line.

[0023] When carrying out power line construction, such as when erecting communication optical cables, there is no need to cut off the power of the transmission line. The two routing pulleys 3 of the device are erected on the conductors to be spanned, and the communication optical cables are passed on the upper rollers 4 to carry out construction. When changing the construction position, push this device, make the line pulley 3 walk on the...

Embodiment 2

[0025] refer to figure 1 , an insulation spanning wire passing machine, comprising a frame-shaped support 1, and "7"-shaped rods 2 are fixedly connected to the vertical poles on both sides of the frame-shaped support 1 to form a fixed clip with an opening downward, and wiring is respectively arranged in the fixed clip The pulley 3 is used to be erected on the spanned wire and walk on the spanned wire. The upper cross bar of the frame support 1 is rotatably connected to the upper roller 4 for supporting the construction line. The lower cross bar of the frame support 1 The connecting end stretches out from the middle part of the rod, and the connecting end is connected with the insulating weight rod 5 .

[0026] When carrying out power line construction, such as when erecting communication optical cables, there is no need to cut off the power of the transmission line. The two routing pulleys 3 of the device are erected on the conductors to be spanned, and the communication optic...

Embodiment 3

[0028] Provided is an insulation spanning wire passing machine, which includes a frame-shaped support, and "7"-shaped rods are fixedly connected to the vertical poles on both sides of the frame-shaped support to form a fixed clip with an opening downward. It is erected on the crossed wire and walks on the crossed wire. The upper cross bar of the frame-shaped support is rotatably connected with the upper roller for supporting the construction line. The upper roller is connected with the upper cross bar bearing of the frame-shaped support. .

[0029] When carrying out power line construction, such as erecting communication optical cables, there is no need to cut off the power of the transmission line. The two routing pulleys of this device are erected on the crossed wires, and the communication optical cables are passed on the upper rollers to carry out construction. When it is necessary to change the construction position, push the device so that the cable pulley can move on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com