Material mixer

The technology of a mixer and feeding tube is applied in mixers, chemical instruments and methods, mixers with rotating stirring devices, etc., which can solve the problems of reducing drug efficacy, tank wall damage, affecting drug efficacy, etc., and achieve practical Strong performance, uniform mixing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

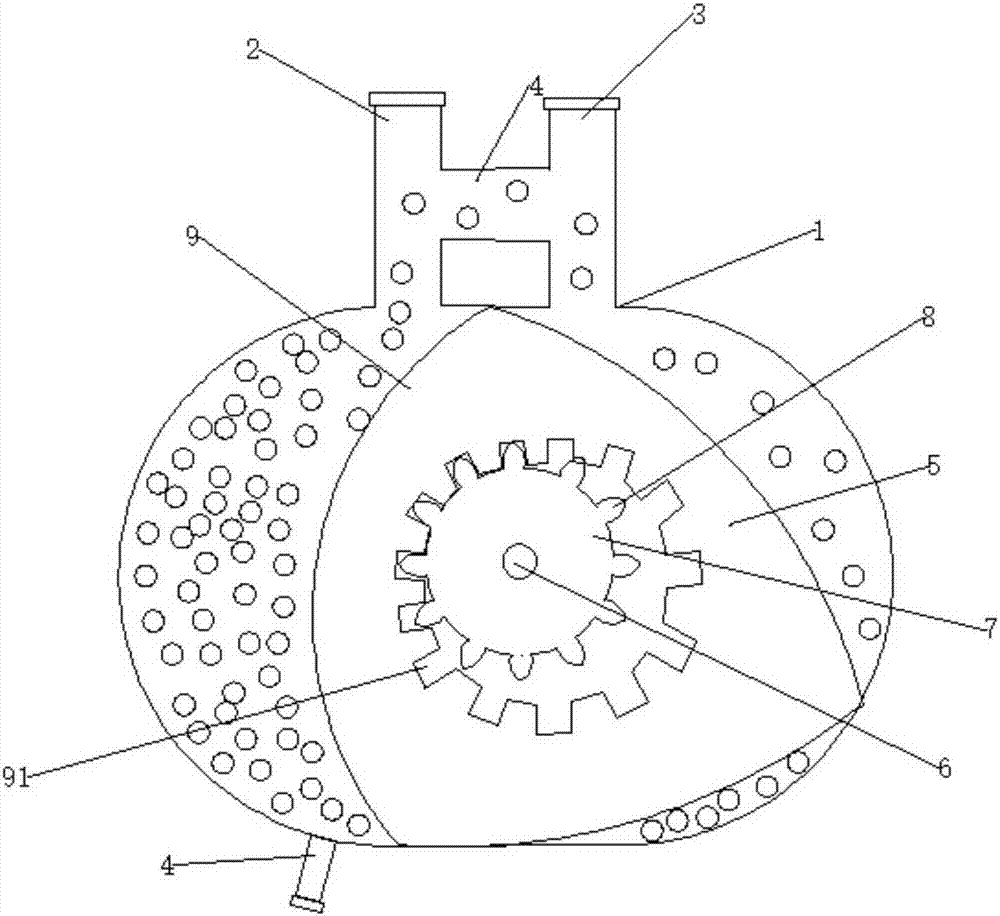

[0015] Such as figure 1 As shown, a kind of mixer, comprises the hollow columnar casing 1 that cross section is ellipse, is provided with the feeding pipe 2 that is arranged in parallel at the top of casing 1, is provided with discharge pipe 3 at the bottom of casing 1, in described A return pipe 4 is horizontally connected between the feed pipes 2, and a columnar swivel 5 is arranged inside the box body 1. The cross section of the swivel 5 is surrounded by three arcs, and the center of the swivel 5 has a hollow Cavity 6, a rectangular groove 7 is provided in the upper direction of the wall of the cavity 6, and a horizontally arranged rotating shaft 8 is provided through the wall of the box body 1, and the rotating shaft 8 extends to the cavity of the rotating body 5 6, the rotating shaft 8 is surrounded by a cylindrical sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com