Installing method for tower type vertical tank

An installation method and vertical tank technology, applied in the direction of lifting devices, etc., can solve the problem that the main arm of the crane is not high enough, and achieve the effect of solving danger and good operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

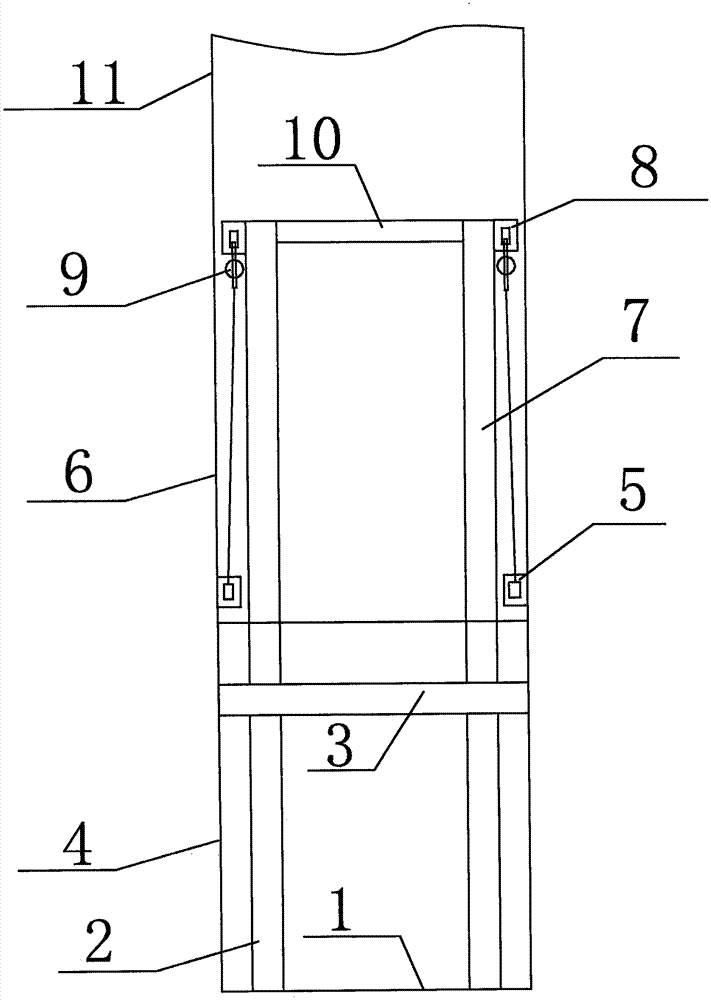

[0008] With reference to the accompanying drawings, the tank body of the tower-type vertical tank is divided into three parts: the upper pipe section 11, the middle pipe section 6, and the lower pipe section 4. The lower pipe section is 2.5 meters in height and is composed of an arc surface coaming. First, install the tower-type vertical tank For the lower body part, the lower pipe section is welded on the bottom plate 1, and a supporting hoisting platform is set in the lower body part of the tower vertical tank. Arranged on the bottom plate at equal intervals around the circumference, welded and fixed with the bottom plate, the platform plate is fixed on the lower column, the platform plate is 2 meters away from the bottom plate, and no less than nine upper columns are arranged on the platform plate at equal intervals on the circumference, and the upper column The length of the column is 3-3.5 meters. Multiple upper support beams cross the center of the circle in a circle form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com