Frame type hydrocylinder compressing bander density control room

A hydraulic cylinder and density control technology, applied in packaging, agricultural machinery and implements, applications, etc., can solve the problems of distracting the driver, single pressing direction, cumbersome operation, etc., to reduce production cost and difficulty, increase rigidity and strength, the effect of reducing product weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

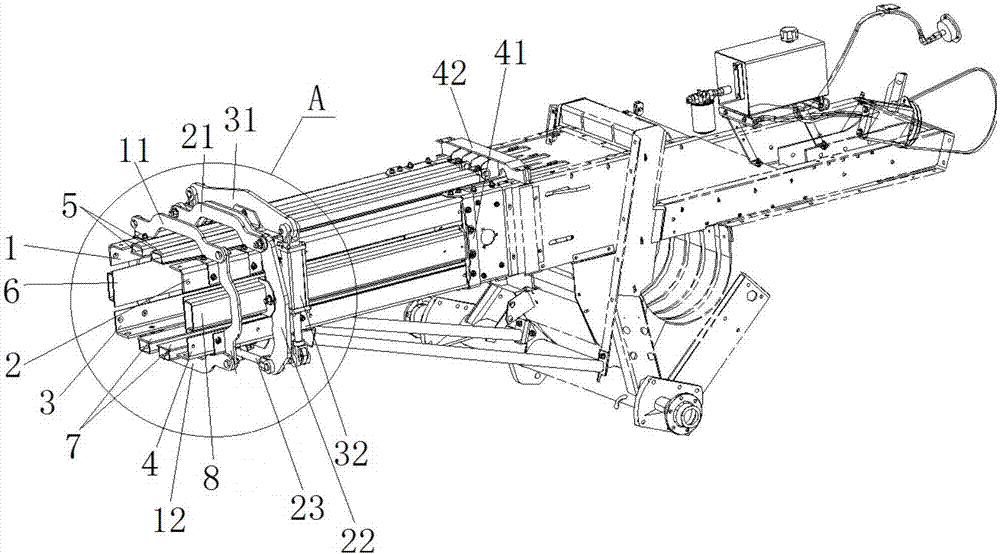

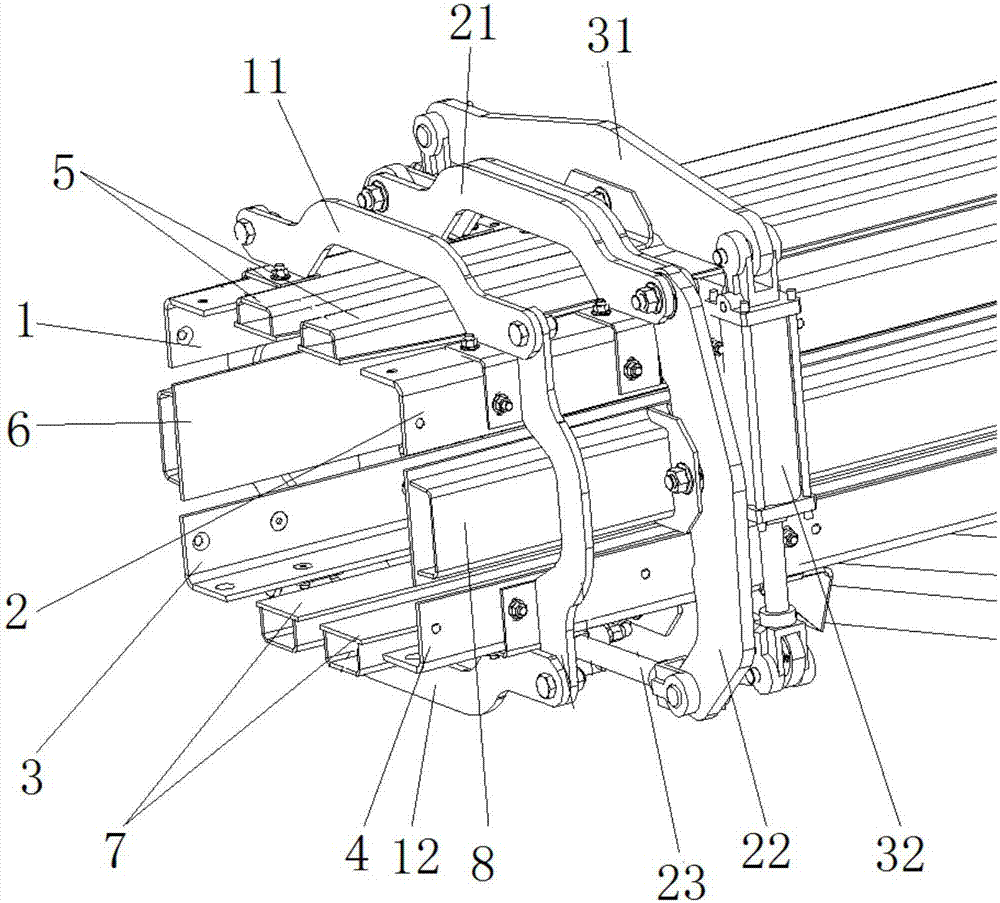

[0029] Such as figure 1 As shown, a frame-type hydraulic cylinder of the present invention compresses the density control room of a baler, including an upper left fixed frame 1, an upper right fixed frame 2, a lower left fixed frame 3, and a lower right fixed frame 4 installed at four corners. Two fixed frames form a rectangle, and mobile frames are installed between two adjacent fixed frames, which are respectively two upper mobile frames 5, two lower mobile frames 7, one left mobile frame 6 and one right mobile frame 8, the frames Three-stage ring frames are installed sequentially in the longitudinal direction.

[0030] The external screws of the two upper moving frames 5 are fixed with foot pieces, and the foot pieces are hinged with the third upper link 31 through the pin shaft. Two vertical hydraulic cylinders 32 are hinged to the pin shafts at both ends of the third upper link 31 and the third lower link. 6 external screws of the left moving frame are fixed with foot p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com