Double-layer filter group and dust collector

A filter group and filter technology, applied in the direction of suction filter, etc., can solve the problems of easy adhesion of oily dust, failure of vacuum cleaner, blockage of filter group, etc., and achieve the effect of simple disassembly, good filtering effect and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

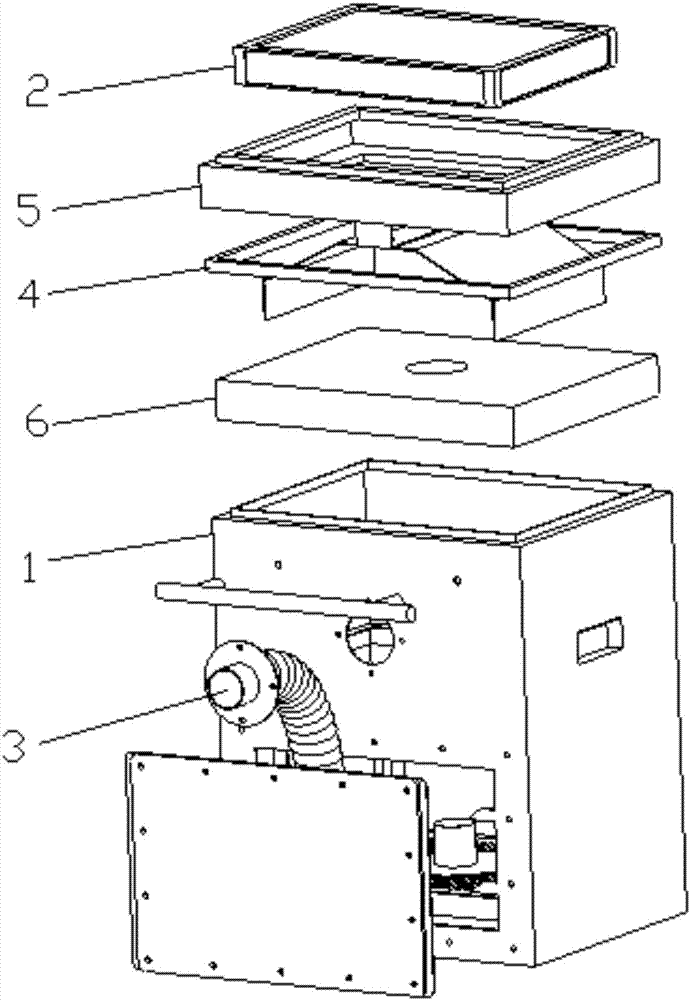

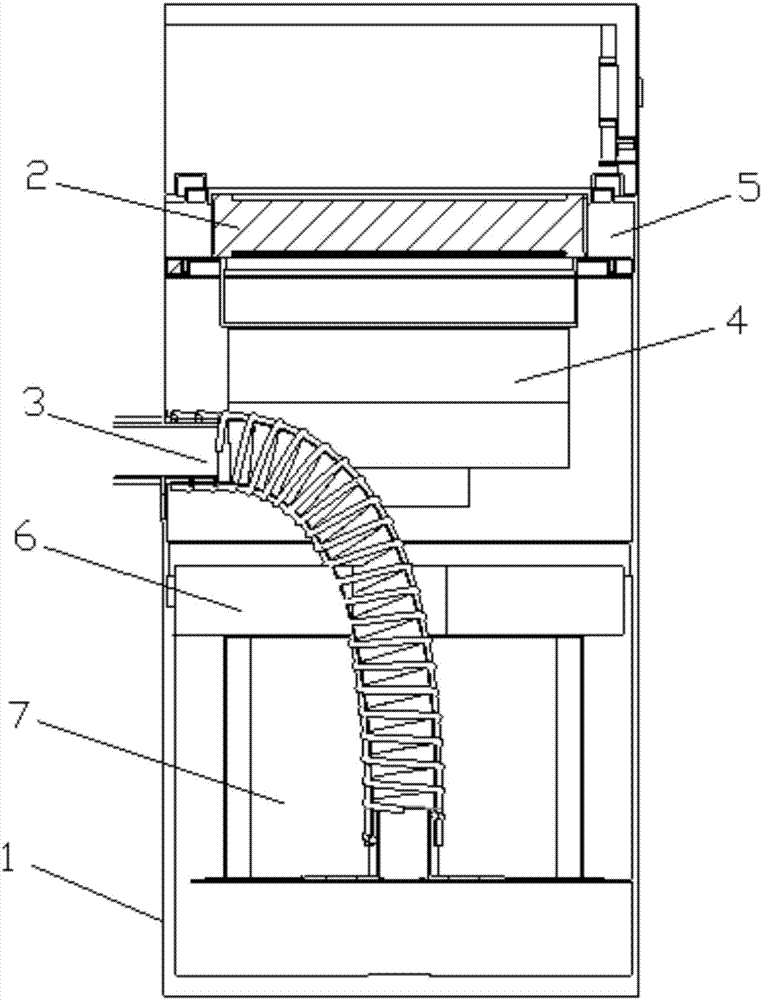

[0023] Such as Figure 1-2 As shown, a double-layer filter set includes a box body 1, a filter 2 and an air inlet pipe 3. The box body 1 is provided with a water baffle 4, and the box body 1 is connected with the water baffle 4 by bolts, The water baffle 4 is provided with a filter mounting frame 5, the filter 2 is mounted on the filter mounting frame 5, the filter 2 is bolted to the filter mounting frame 5, and the water baffle 4 is below A water blocking net 6 is provided, and the water blocking net 6 is bolted to the box body 1, a seal (not shown) is arranged between the filter mounting frame 5 and the box body 1, and the filter mounting frame 5 is connected to the box body 1 is sealed by a seal, a water storage cavity 7 is formed under the water blocking net 6, the air inlet pipe 3 is arranged through the water blocking net 6, and the end of the air inlet pipe 3 is located in the water storage cavity 7, so The head end of the air inlet pipe 3 is communicated with the outsid...

Embodiment 2

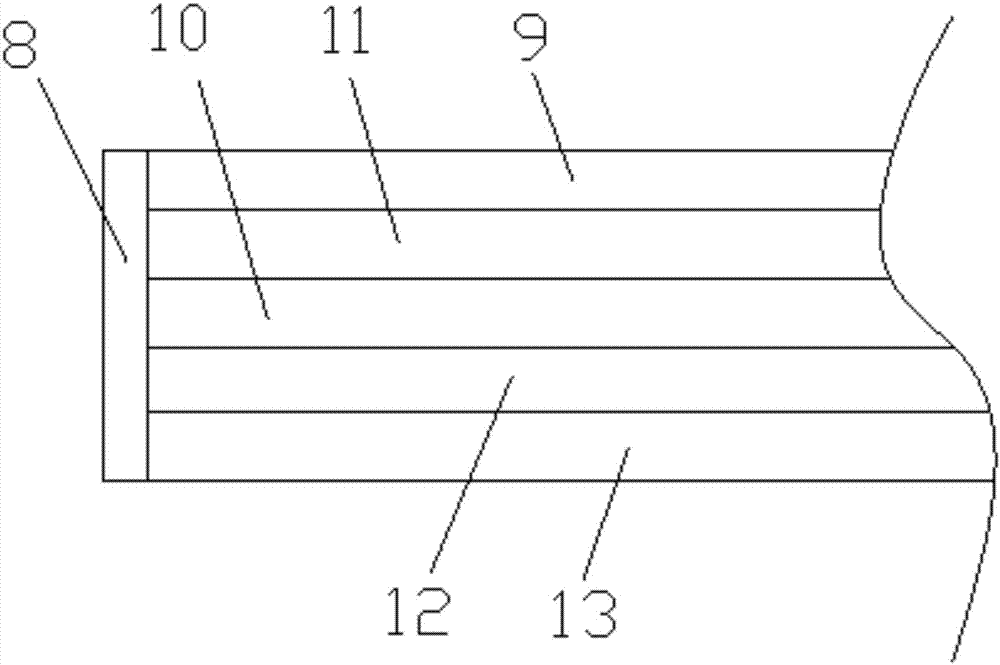

[0026] Such as Figure 1-4 As shown, a double-layer filter group includes a box body 1, a filter 2 and an air inlet pipe 3. The box body 1 is bolted with a water baffle 4, and a filter installation is provided on the water baffle 4 The filter 2 is mounted on the filter mounting frame 5, the filter 2 is bolted to the filter mounting frame 5, the filter mounting frame 5 is bolted to the box body, and the water baffle 4 A water blocking net 6 is provided below, the water blocking net 6 is connected with the box body by bolts, a water storage cavity 7 is formed under the water blocking net 6, and the air inlet pipe 3 is arranged through the water blocking net 6, and the inlet The end of the air pipe 3 is located in the water storage cavity 7, and the head end of the air inlet pipe 3 is in communication with the outside. The sides of the water baffle 4 and the side of the water blocking net 6 are both bonded with a sealing tape 8. The sides of the water blocking plate 4 and the sid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap