Automatic tea leaf sorting device

An automatic sorting and tea technology, which is applied in grading, solid separation, tea treatment before extraction, etc., can solve the problems of increased workload and inability to remove impurities such as sand and stones, and achieve less energy loss, faster rotation acceleration, and friction The effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

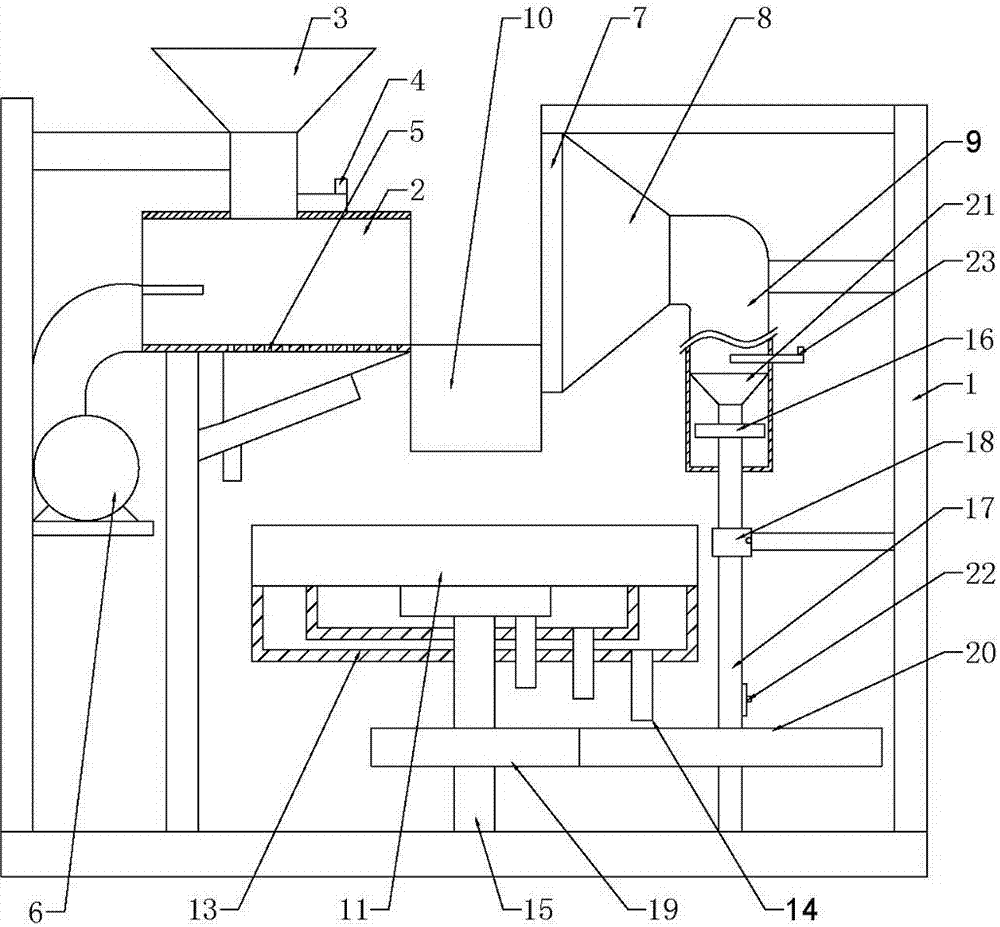

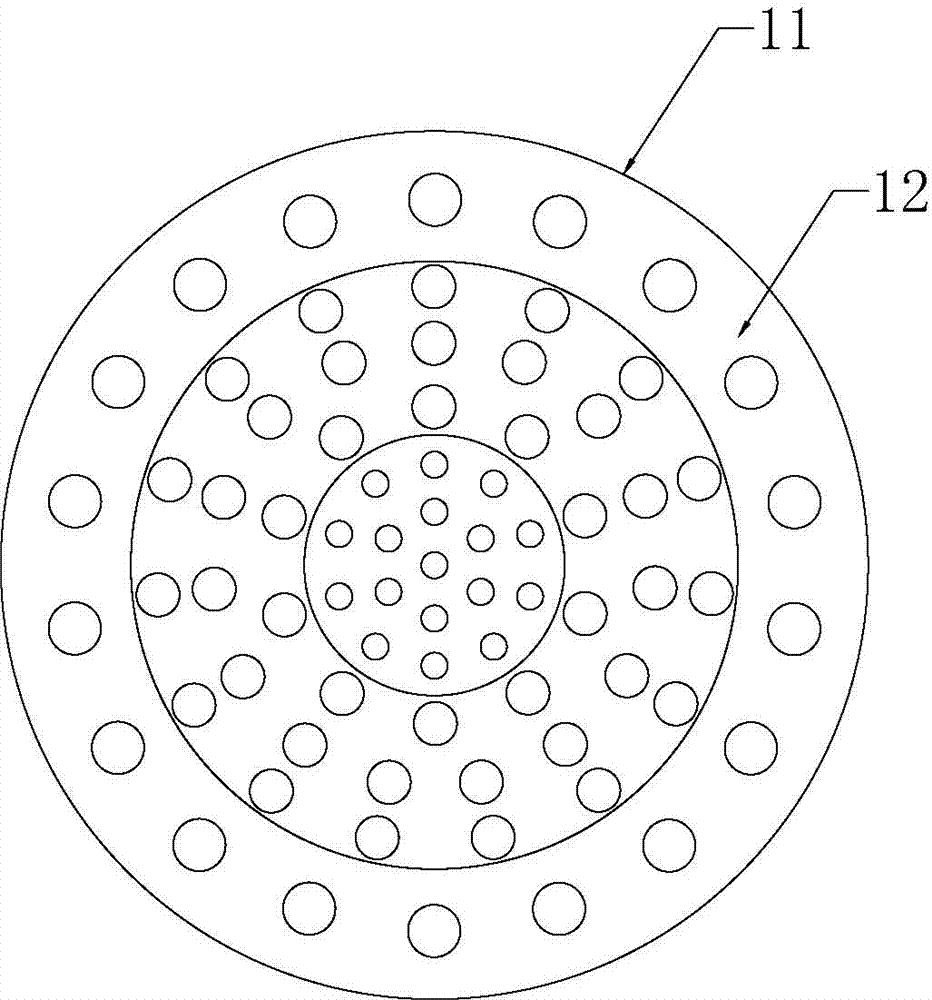

[0019] The reference signs in the drawings of the description include: frame 1, sand removal pipe 2, hopper 3, regulating valve 4, through hole 5, fan 6, filter screen 7, wind collecting hood 8, ventilation pipe 9, drop pipe 10, Disc 11, filter plate 12, collection box 13, slideway 14, first rotating shaft 15, windmill 16, second rotating shaft 17, collar 18, first gear 19, second gear 20, conical filter cover 21, outlet Shakou 22, air flow regulating valve 23.

[0020] Example basic reference figure 1 and figure 2 Shown: the tea automatic sorting device, including a frame 1, on which a sand removal pipe 2 is fixed horizontally through bolts, and the upper side of the sand removal pipe 2 is connected to a hopper 3, which is in an inverted cone shape, and the hopper 3 The upper slide is provided with a regulating valve 4 for adjusting the falling flow of tea leaves, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com