Integrated stainless steel pipe production line

A stainless steel pipe and production line technology, which is applied in the direction of manufacturing tools, casting workshops, metal processing equipment, etc., can solve the problems of long production cycle, many production processes, and high labor intensity of workers, and achieve short forming cycle, high production efficiency, good use foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to deepen the understanding of the present invention, the following further describes the present invention with reference to the accompanying drawings and embodiments. The embodiments are only used to explain the present invention and do not limit the protection scope of the present invention.

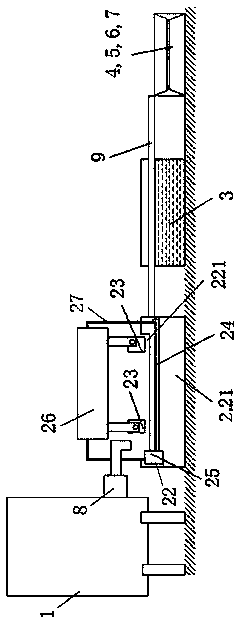

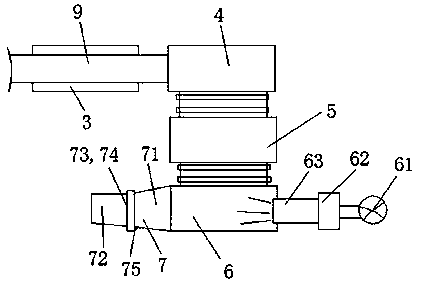

[0015] Such as figure 1 As shown, the integrated stainless steel pipe production line includes a smelting furnace 1, steel pipe forming equipment 2, water cooling pool 3, infrared correction workbench 4, tempering treatment equipment 5, air cooling equipment 6 and collection device 7 connected in sequence; among them: The steel pipe forming equipment 2 includes a steel pipe forming table 21, a steel pipe lower mold 22, a mandrel 23, and a transparent sliding cover 27. The steel pipe lower mold 22 is automatically controlled on the steel pipe forming table 21 through a slide rail 24 and a sliding power source 25 Slide and unload the molded steel pipe; the mandrel 23 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com