Multi-motor electric vehicle driving axle structure

A technology for electric vehicles and drive axles, applied in the field of vehicles, can solve problems such as difficult high-efficiency conversion of electric energy, inability of vehicles to drive, large installation space, etc., to achieve the effects of flexible arrangement of installation space, realization of motor efficiency, and reduction of motor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

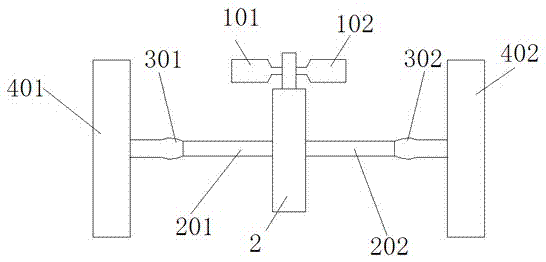

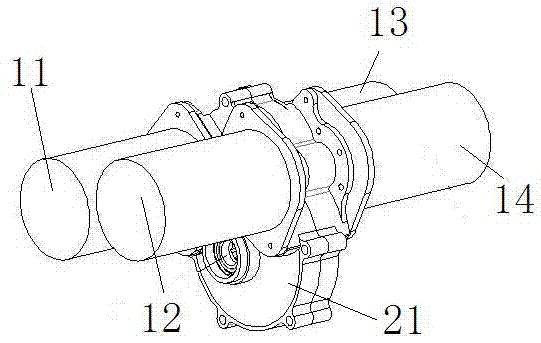

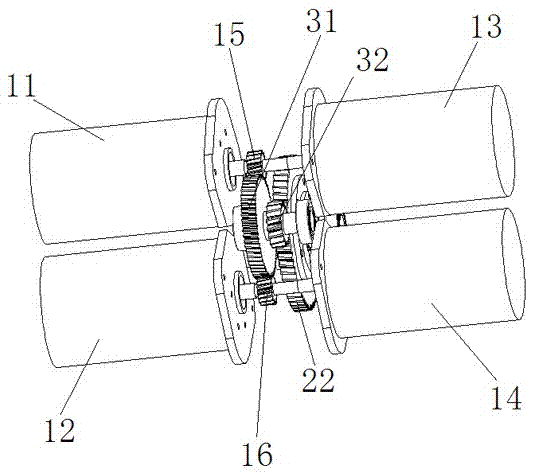

[0010] The present invention is further explained in detail in conjunction with the accompanying drawings. In the accompanying drawings, each mark is: 101: motor A; 102: motor B; 2: differential; 201: left half shaft; 202: right half shaft; 301: left universal 302: right universal joint; 401: left drive wheel; 402: right drive wheel; 11: motor one; 12: motor two; 13: motor three; 14: motor 4; 15: output gear one; 16: output Gear two; 22: differential input wheel; 31: intermediate wheel one; 32: intermediate wheel two; 21: differential housing. As shown in the figure, the drive axle structure of a multi-motor electric vehicle includes a differential 2, the output shafts of more than two motors are dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com